Technical standard of cylinder cover inner hole platform honing reticulate pattern based on three-dimension

A technology for honing reticulate patterns and cylinder liners, which is applied in the field of technical standards, can solve problems such as inability to reflect essential characteristics, distortion of measurement results, and greater influence, and achieve the effects of reducing the number of parameters, preventing parameter explosion, and changing low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with specific embodiments. It should be understood that the examples are only for illustration of the present invention and are not intended to limit the scope of the present invention in any way.

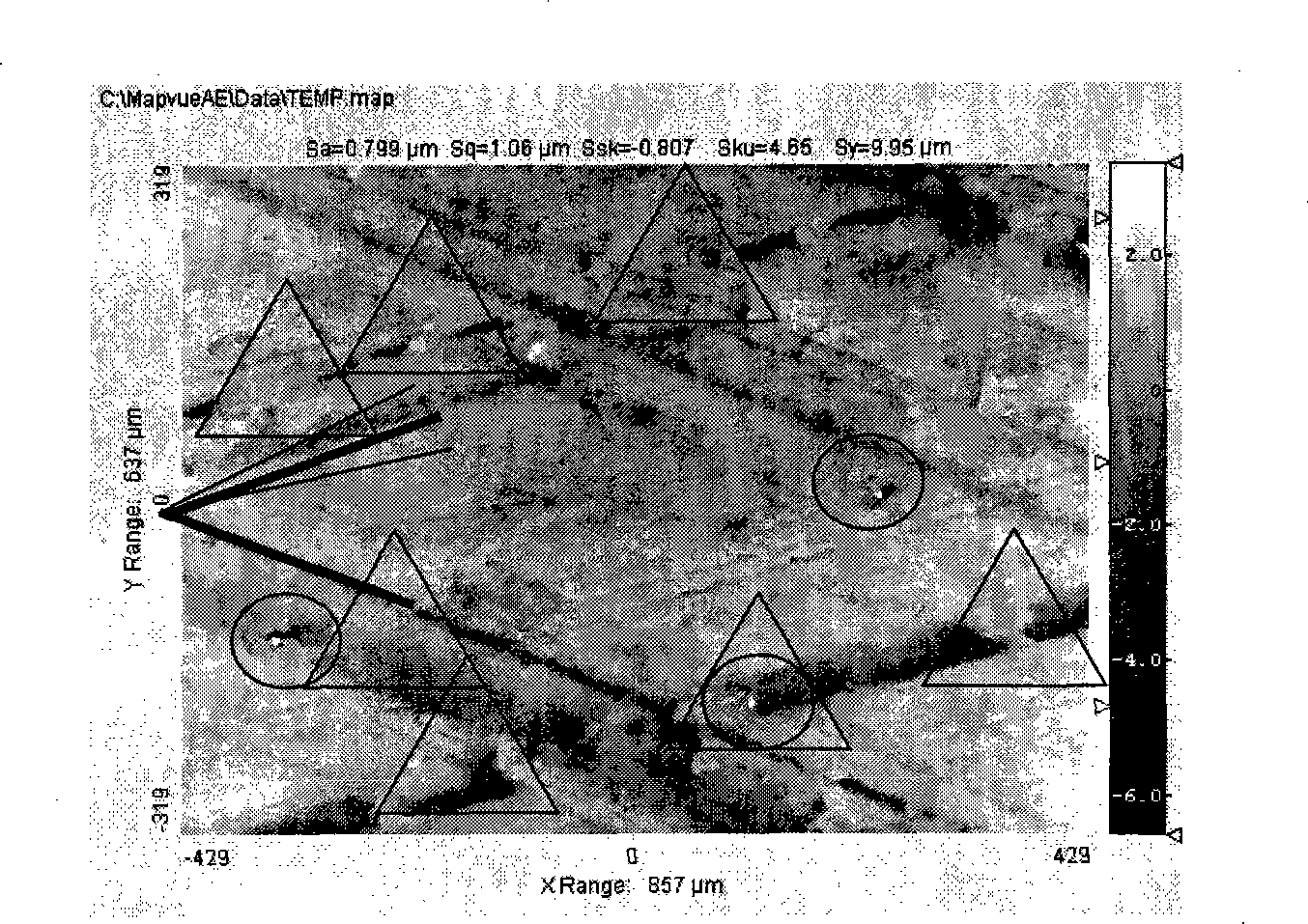

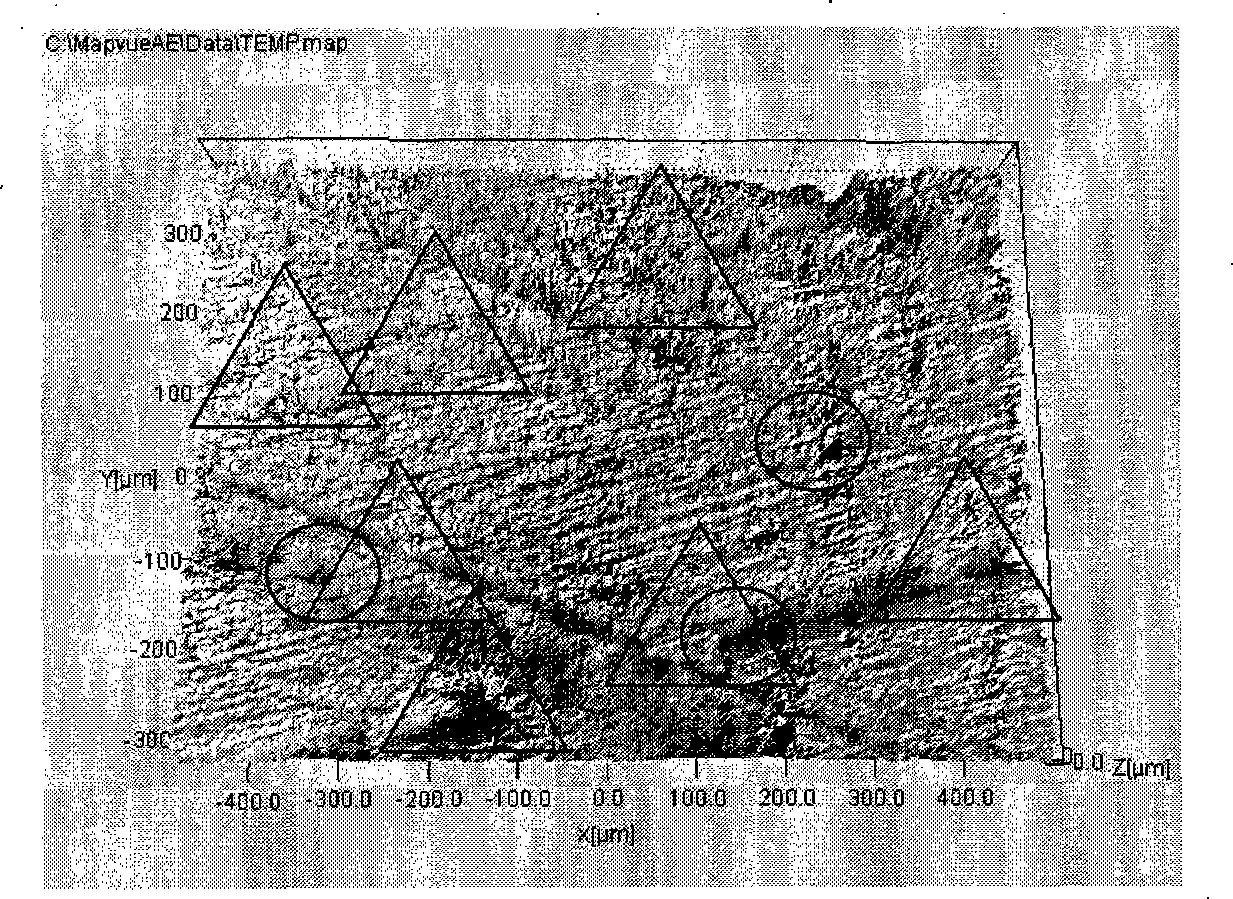

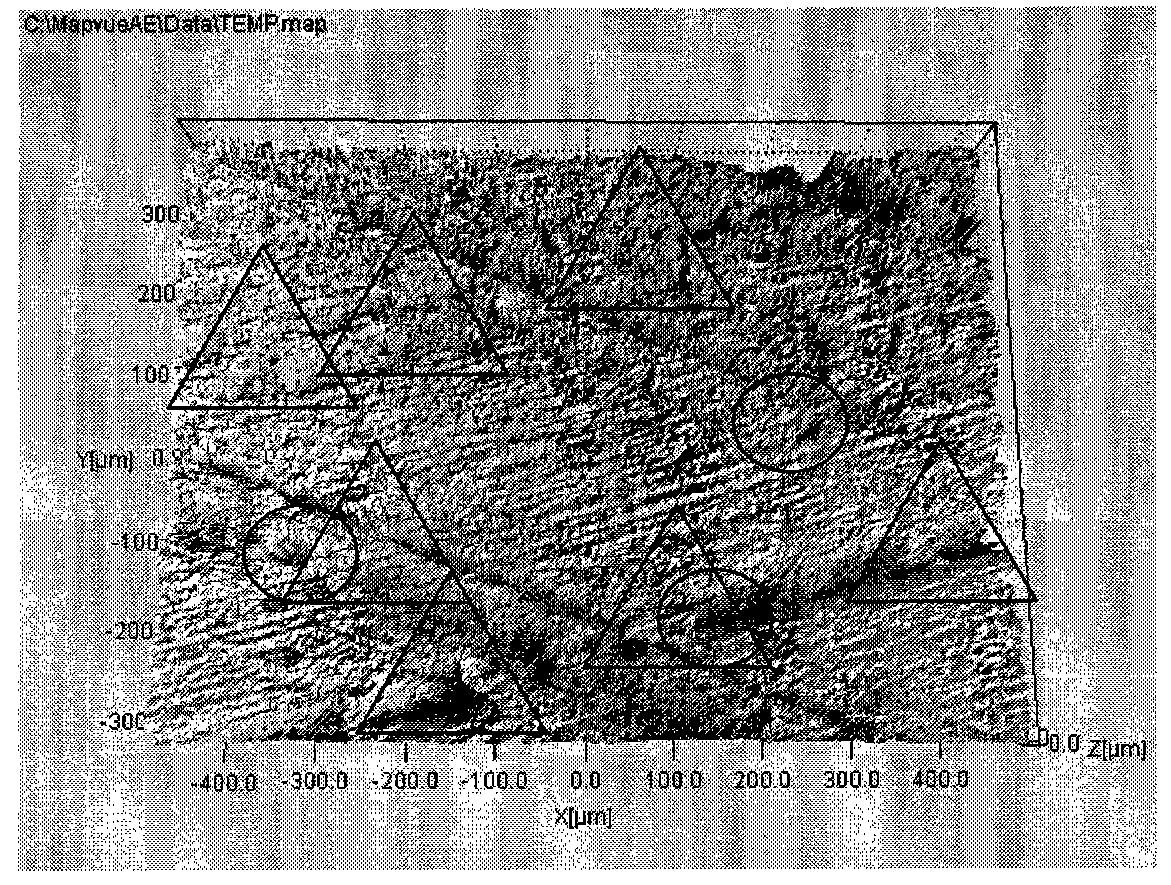

[0063] Using MicroXAM produced by American ADE Company TM The non-contact surface three-dimensional topography instrument scans the genuine cylinder liner and obtains figure 1 , figure 2 The two-dimensional and three-dimensional images of the platform honing anilox are shown, and the measurement conditions are set to the objective lens magnification of 10×, the scanning height of 80 μm, and the scanning range of 857 μm×637 μm.

[0064] Read out the following three-dimensional parameter values through the three-dimensional profiler:

[0065] 1. Evaluate surface defect parameters (take the average value of three places): the standard is that the texture is clear, and the unit area (mm 2 ) of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com