Nickel-based high-temperature alloy and preparation method thereof

A technology of nickel-based superalloy, mass percentage content, applied in the field of alloy smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

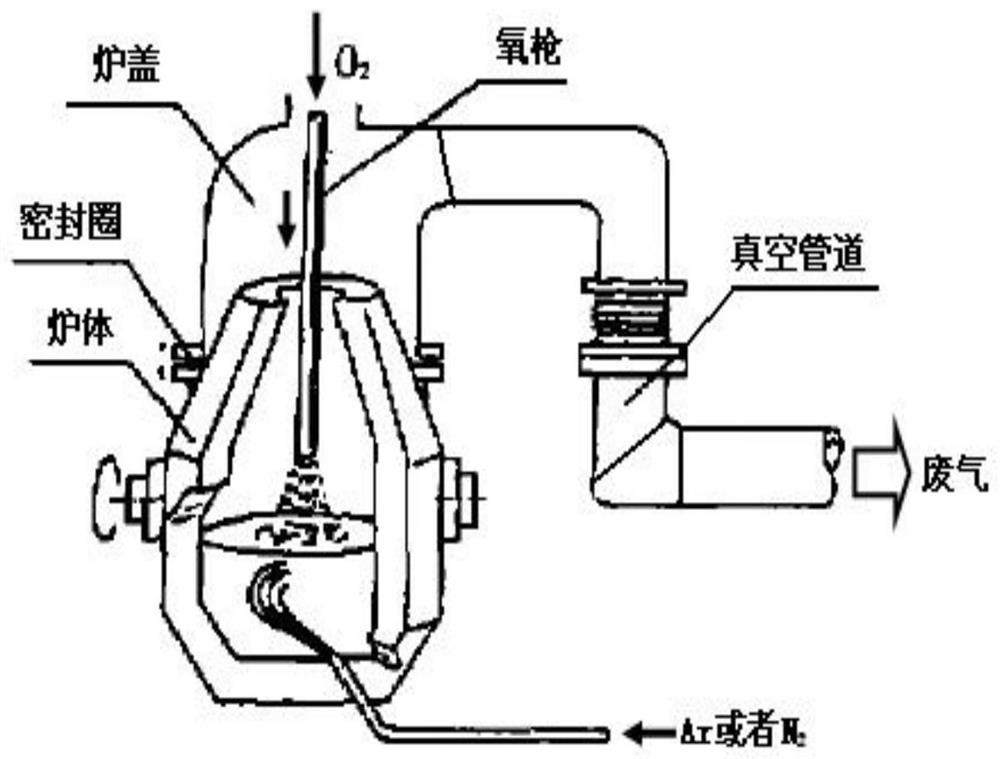

[0037] The present invention also provides a method for preparing the nickel-based superalloy described in the above technical solution, comprising the following steps:

[0038] The alloy raw materials are subjected to rough refining, refining, VODC method degassing and pouring in sequence to obtain steel ingots;

[0039] Annealing the steel ingot to obtain the nickel-based superalloy.

[0040] In the invention, alloy raw materials are sequentially subjected to rough refining, refining, VODC method degassing and pouring to obtain steel ingots.

[0041] In the present invention, the rough smelting preferably includes EAF electric arc furnace rough smelting; the EAF electric arc furnace rough smelting preferably includes melting, oxidation and reduction in sequence.

[0042] In the present invention, the melting power is preferably 4800-5000 kV·A, more preferably 4900 kV·A; the temperature is preferably ≥1620°C, more preferably 1620-1700°C. In the present invention, the mass p...

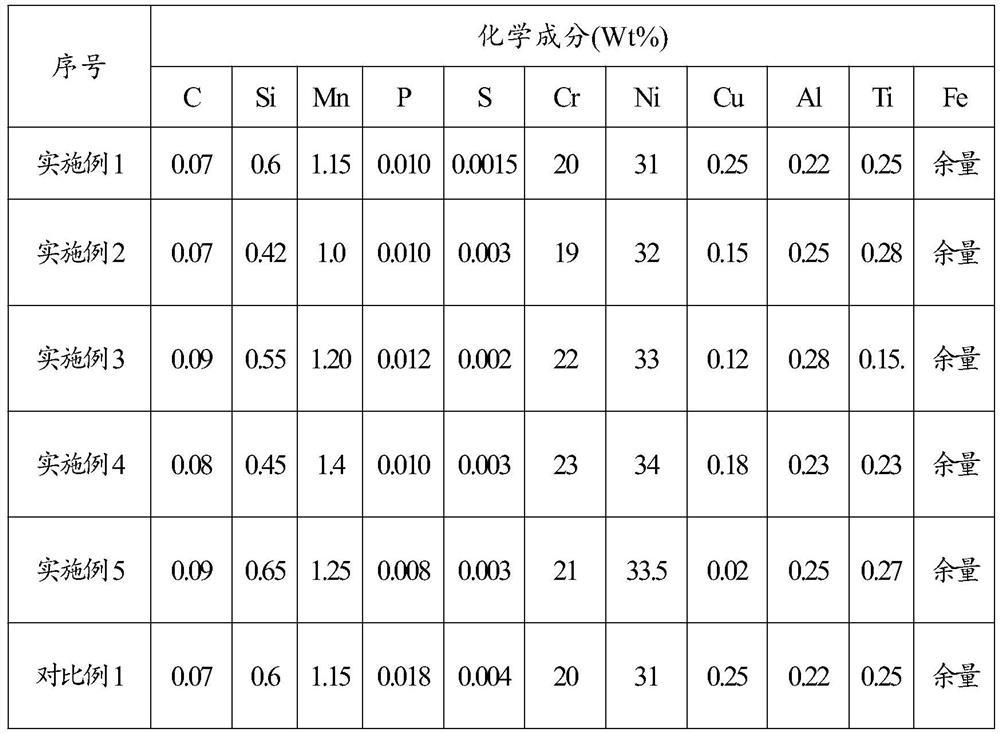

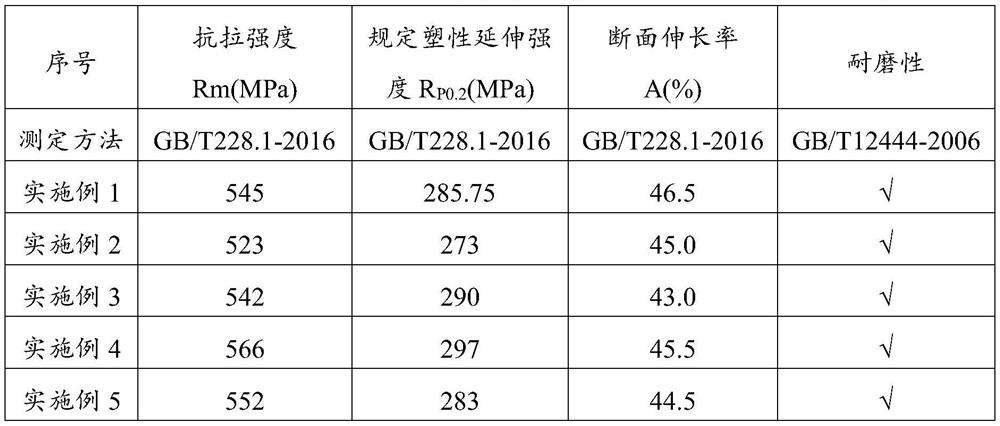

Embodiment 1

[0059] The ratio of raw materials is C 0.07%, Si 0.6%, Mn 1.15%, P 0.05%, S 0.01%, Cr 20.0%, Ni31.0%, Cu 0.25%, Al 0.22%, Ti 0.25%, and the balance is Fe raw material.

[0060] Preparation methods include:

[0061] Weigh the alloy raw material according to the above composition, place it in the EAF electric arc furnace for rough smelting in the EAF electric arc furnace; melting stage: the power is 4800KV·A, the temperature is 1620°C, the mass content of P in the system to be melted is ≤0.004%, and the oxidation stage is carried out ; The power in the oxidation stage is 4500KV·A, the temperature is 1650°C, the mass percentage of C in the system to be oxidized is ≤0.15%, and it enters the reduction stage; the power in the reduction stage is 4500KV·A, and the temperature is 1650°C; the system to be reduced The medium slag (FeO) is about 5%, S≤0.005%, and then enters the LF refining furnace for refining in the LF refining furnace; the conditions for refining in the LF refining fu...

Embodiment 2

[0064] The ratio of raw materials is: C 0.07%, Si 0.42%, Mn 1.0%, P 0.06%, S 0.02%, Cr 19.0%, Ni32%, Cu 0.15%, Al 0.25%, Ti 0.28%, and the balance Fe.

[0065] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com