Method of reflow soldering a printed circuit board wherein an electroconductive coating material is used

A technology of printed circuit substrate and conductivity, which is applied in the direction of assembling printed circuit with electrical components, printed circuit, and printed circuit manufacturing, etc. It can solve the problem of short preheating time, uneven flux, pad patterns that cannot be applied to conductive coatings, etc. Soldering problems, achieving excellent solder joint strength and good solder leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

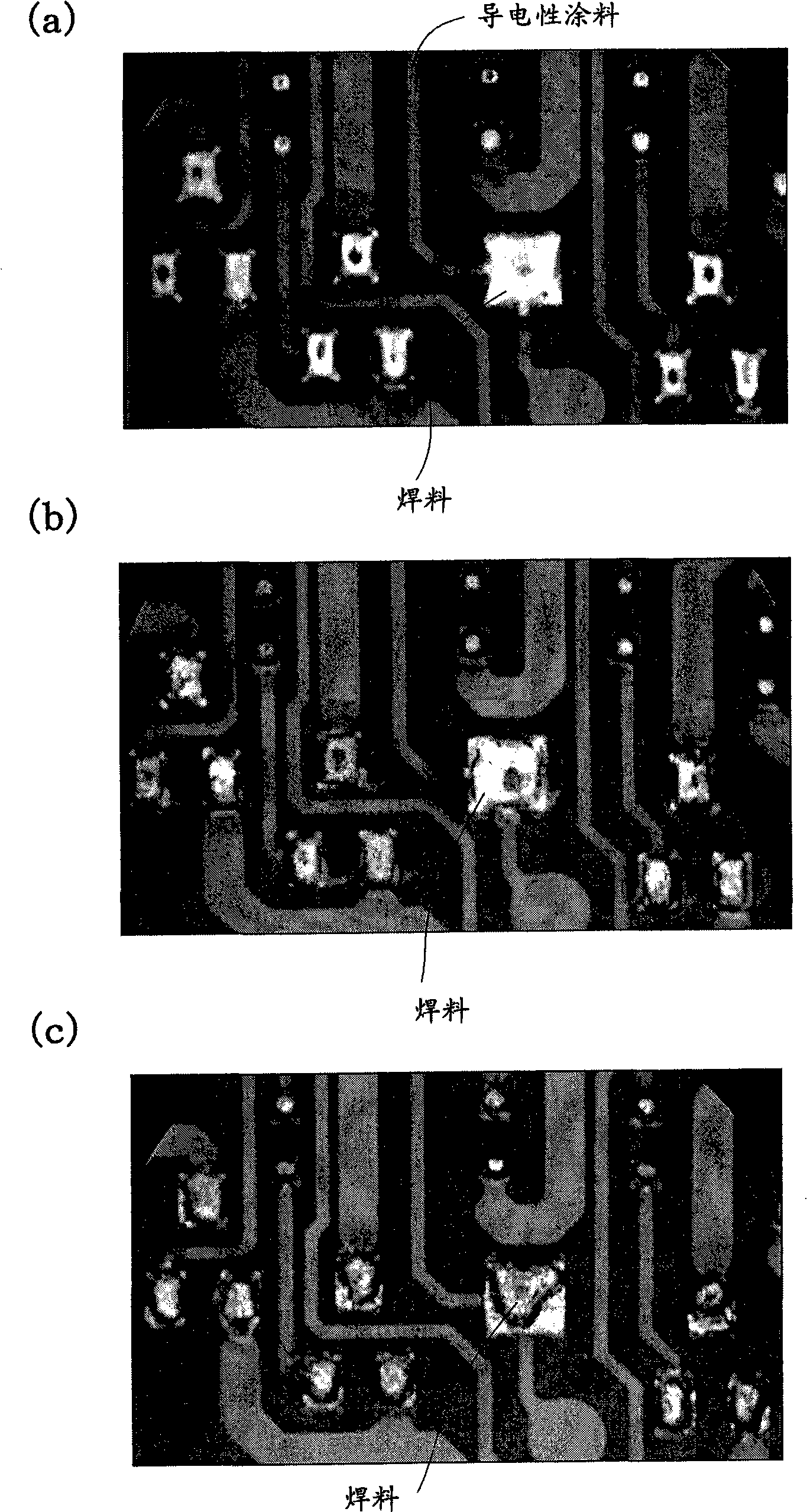

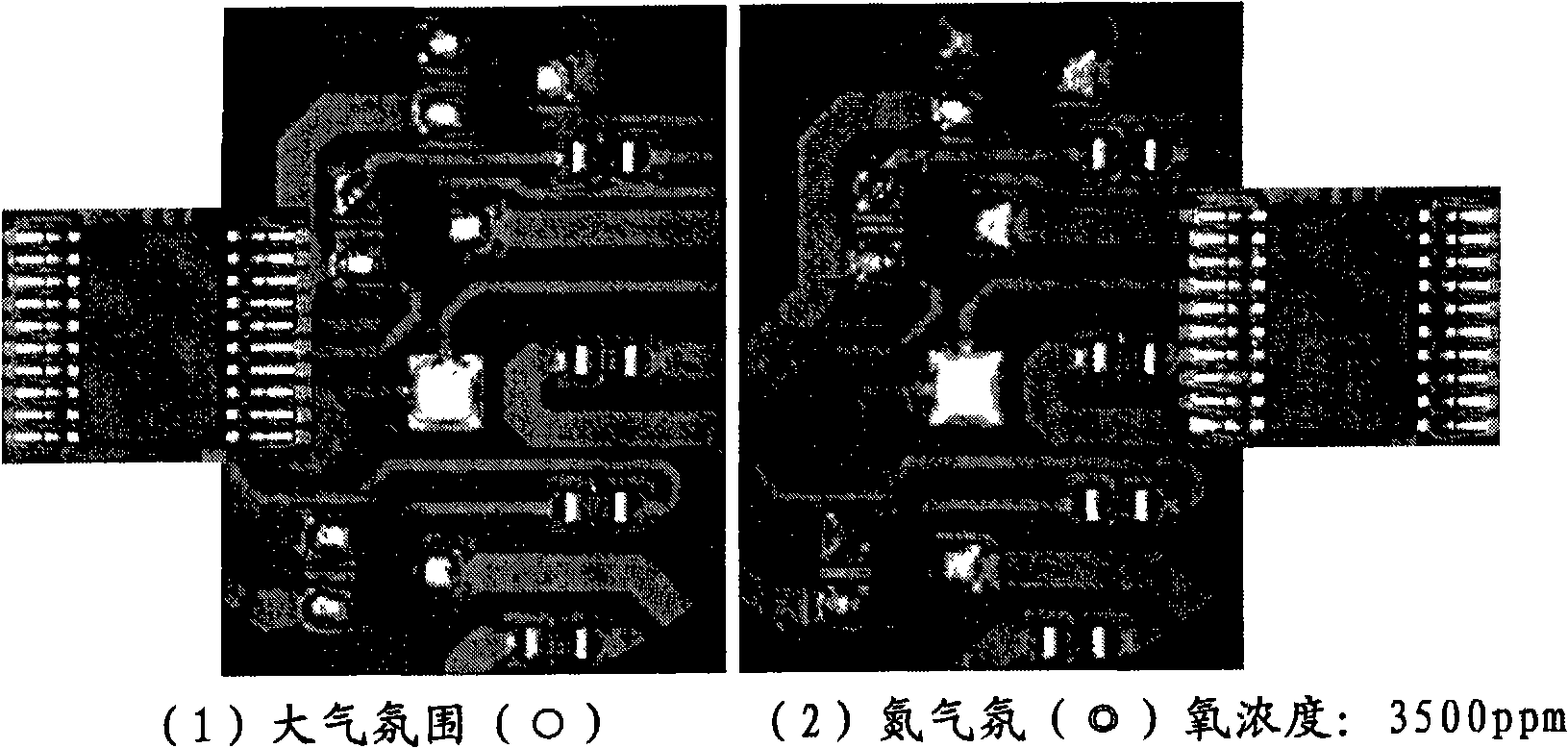

[0030] The reflow soldering method according to the present invention can be applied to various electronic substrates using conductive paint for land patterns, but in this embodiment, the case of using it as a substrate of a remote controller for remotely operating electronic equipment is used as an example. Evaluation was performed, and it demonstrates below.

[0031] As a phenolic paper substrate material in which a phenolic resin is permeated into a paper substrate, a substrate material with a thickness of 1.6 mm and an absorption rate of 2.0% (manufactured by Rishang Kogyo Co., Ltd., PS-1131) with a resist layer coated on it was prepared. (Resist manufactured by Tamura Manufacturing Co., Ltd., FINEDELDSR-330R14-13) is used as a substrate material, and a wiring pattern is screen-printed with a conductive paint.

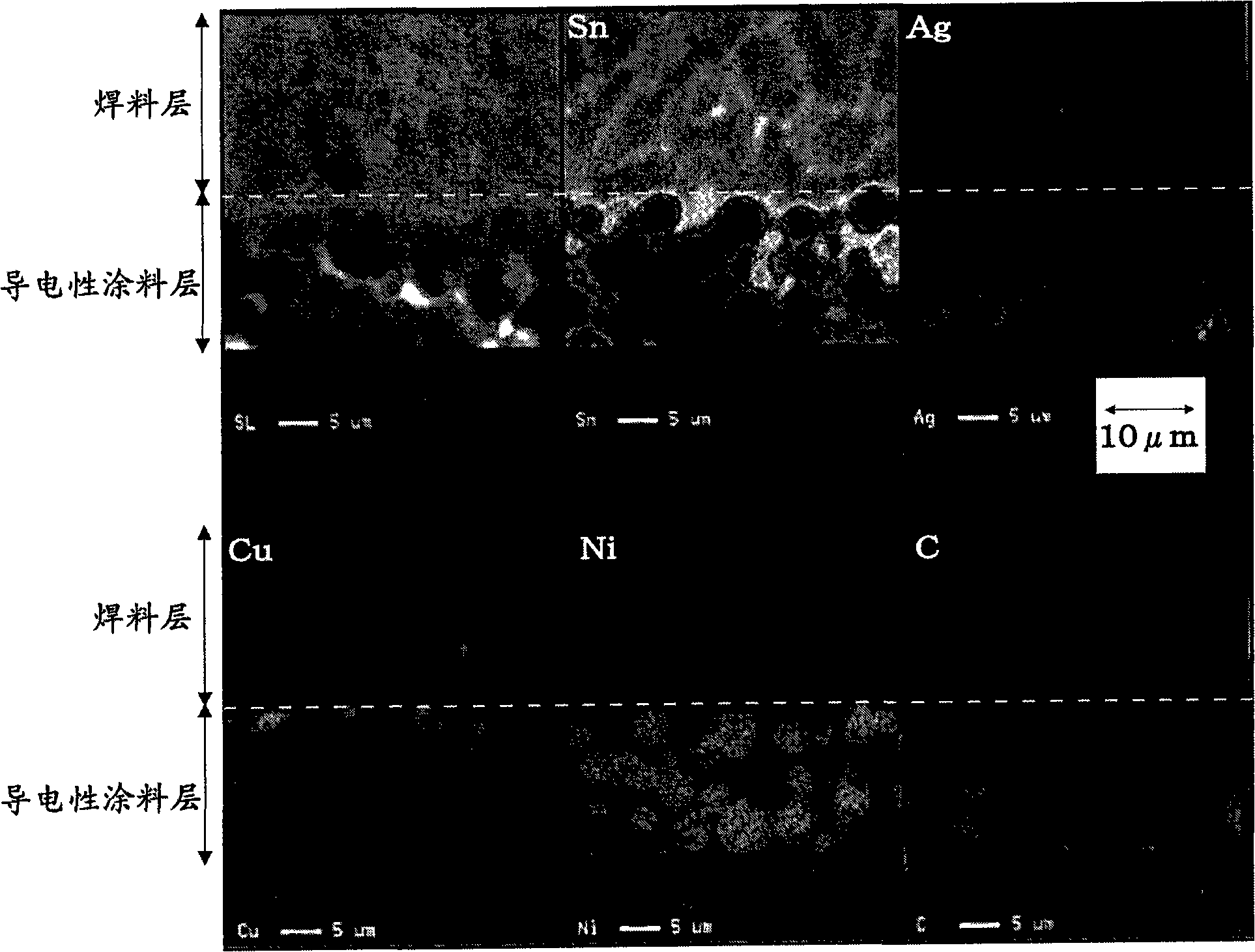

[0032] The conductive paint used in the evaluation is a conductive paint manufactured by Maxell Hokuriku Seiki Co., Ltd. Ni powder coated with Ag is mixed with Ag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com