Sintered ceramic product having a nitrogenous mold with improved surface properties

A technology for sintering ceramics and products, applied in transportation and packaging, thin material handling, etc., can solve the problems of time-consuming and expensive operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

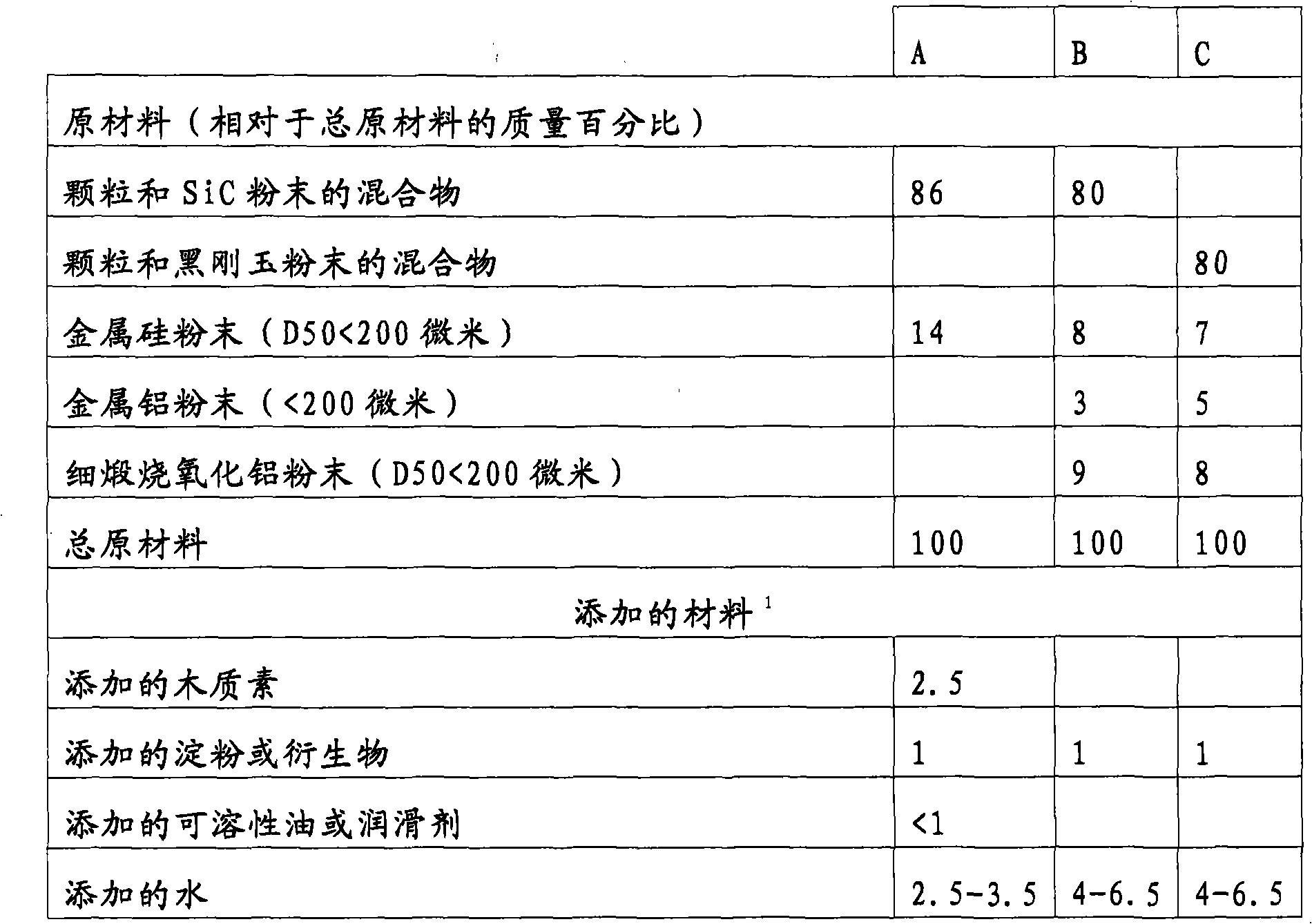

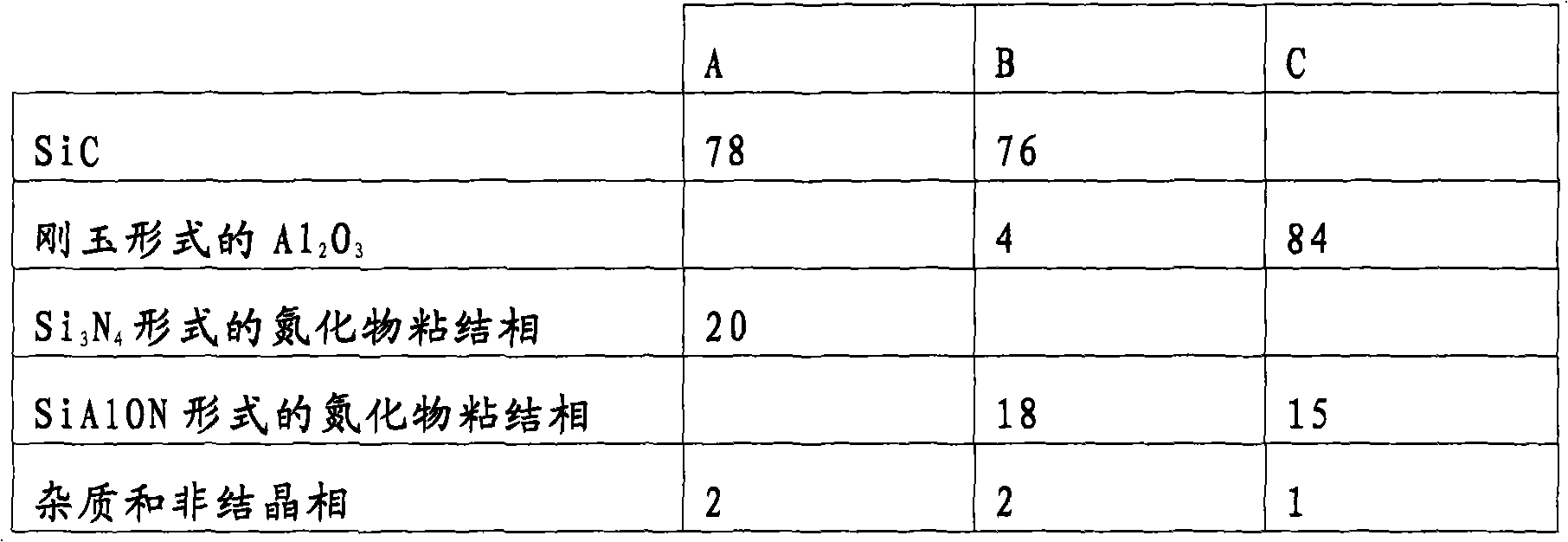

Method used

Image

Examples

Embodiment Construction

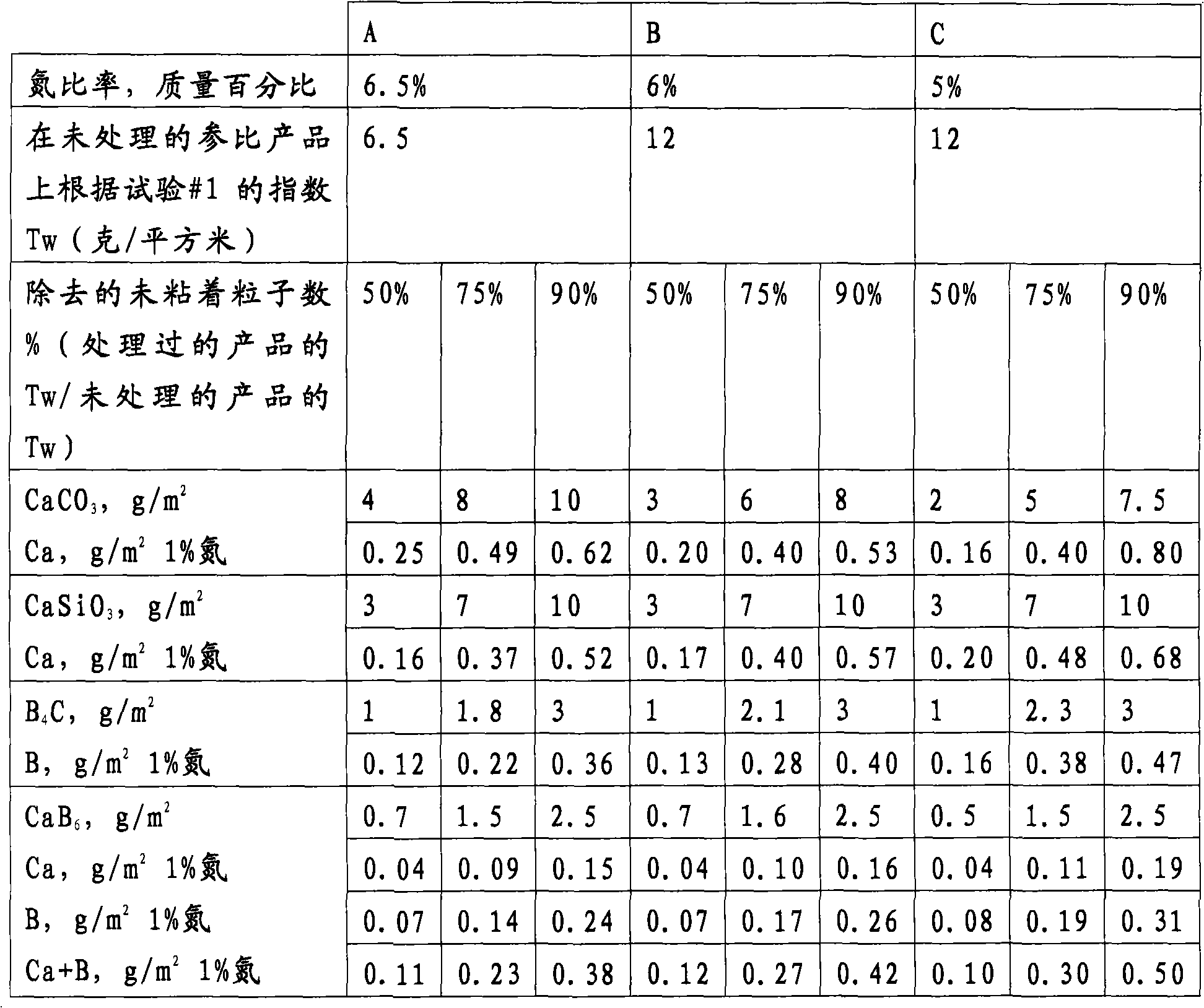

[0073] The invention is further illustrated in the following non-limiting examples.

[0074] · To characterize the ratio of unadhered particles (Test #1), a 48 mm wide adhesive tape, such as Scotch Box Sealing Tape 355 (polyester and synthetic rubber resin) was applied to the surface of the product under test and then peeled off. This operation is repeated until all unattached particles are removed from the surface. Observation of the adhesive surface of the tape with a scanning electron microscope confirmed that only unadhered particles were removed and not particles (having a diameter greater than 200 microns). Thereafter, the peeled material was weighed and divided by the surface area of the tape adhered to the surface of the product under test to obtain the Tw index in grams / square meter. This measurement is combined with observation of the surface of the product under test using a scanning electron microscope to verify that all non-adhered particles have been properl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap