Printing machine ink amount supply automatic control system

An automatic control system and printing machine technology, applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of complex system configuration and connection, inconvenient installation and maintenance, low reliability and precision, etc., to achieve Improve detection and control accuracy, facilitate installation and maintenance, and make up the effect of simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

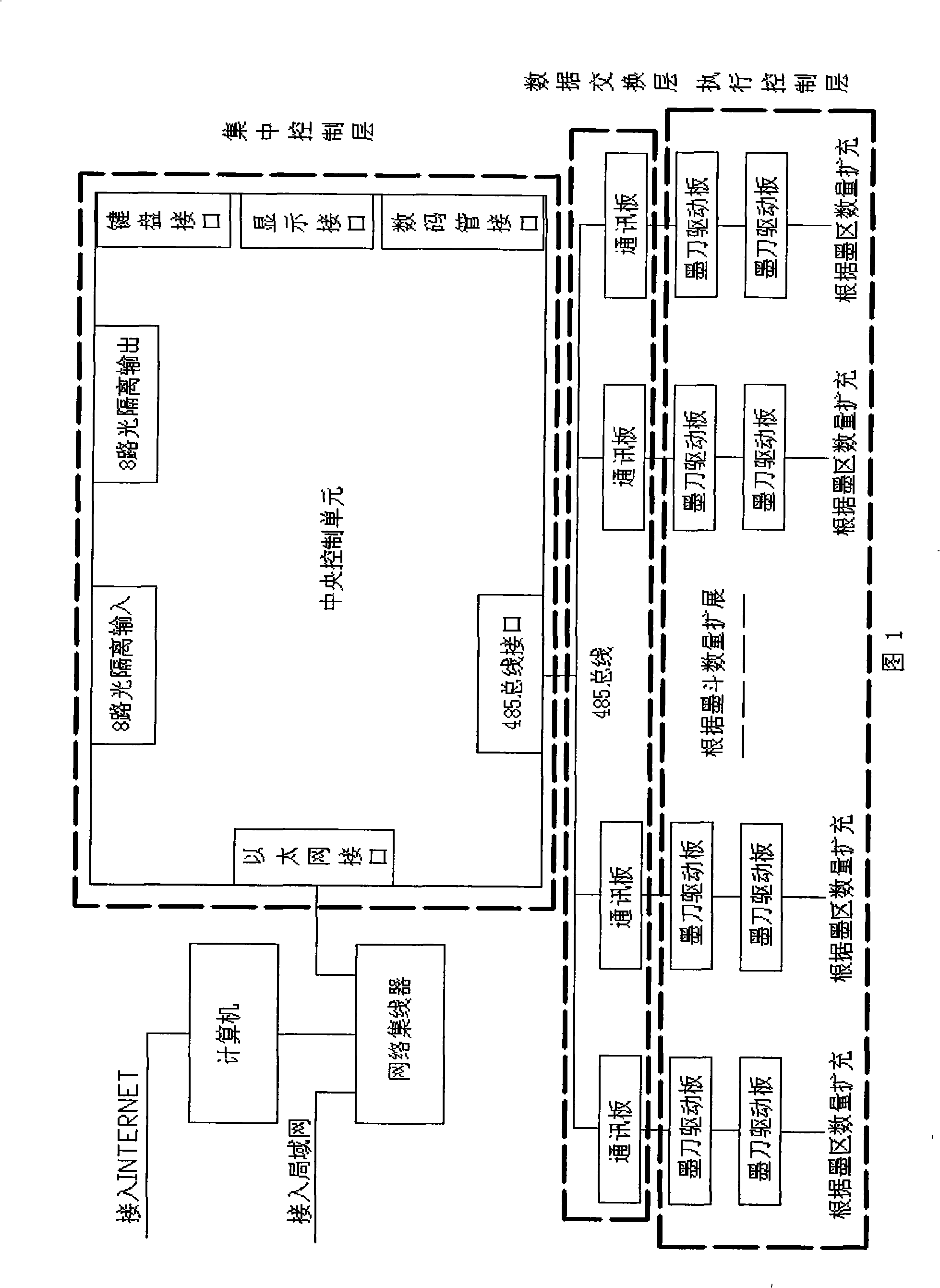

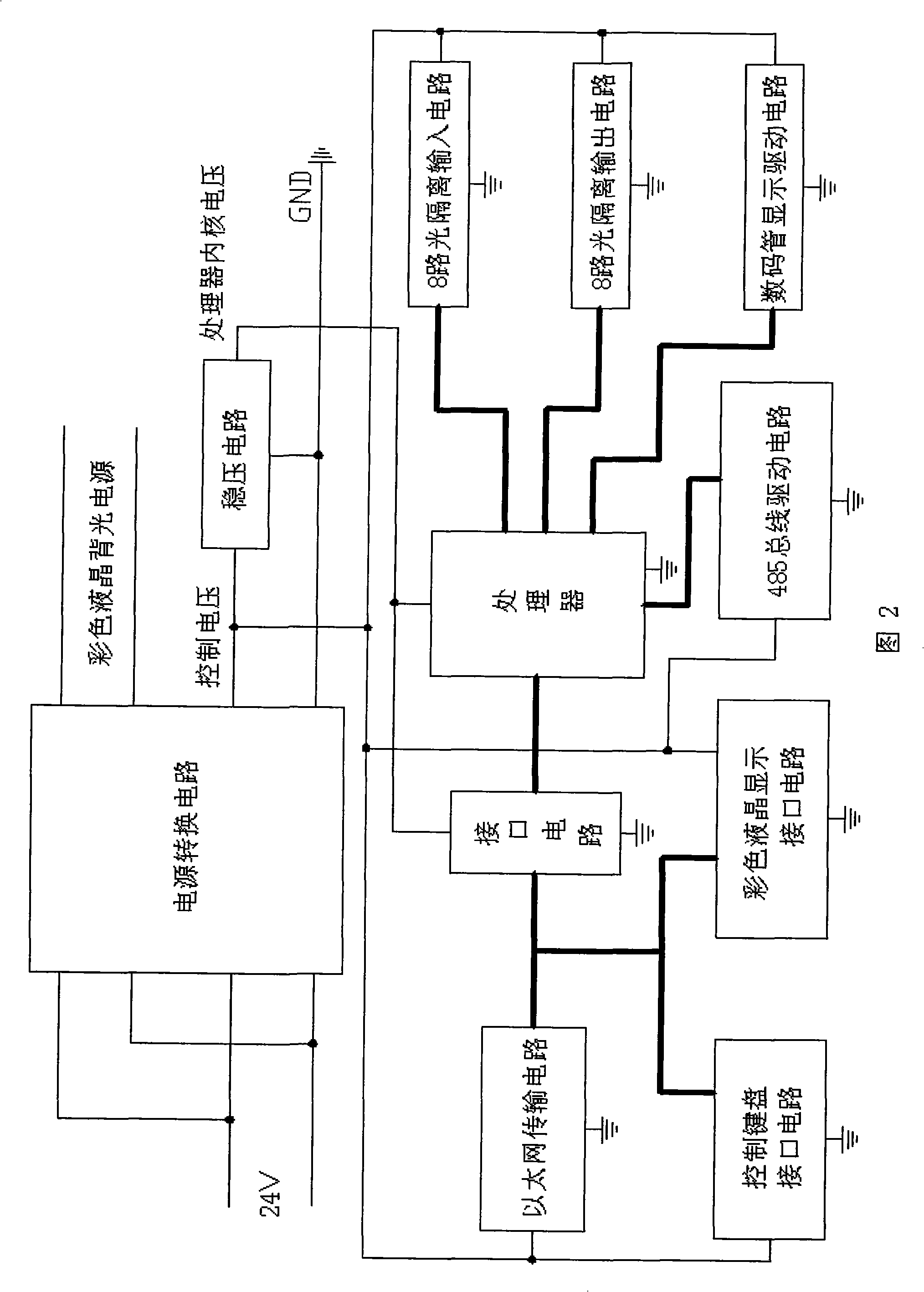

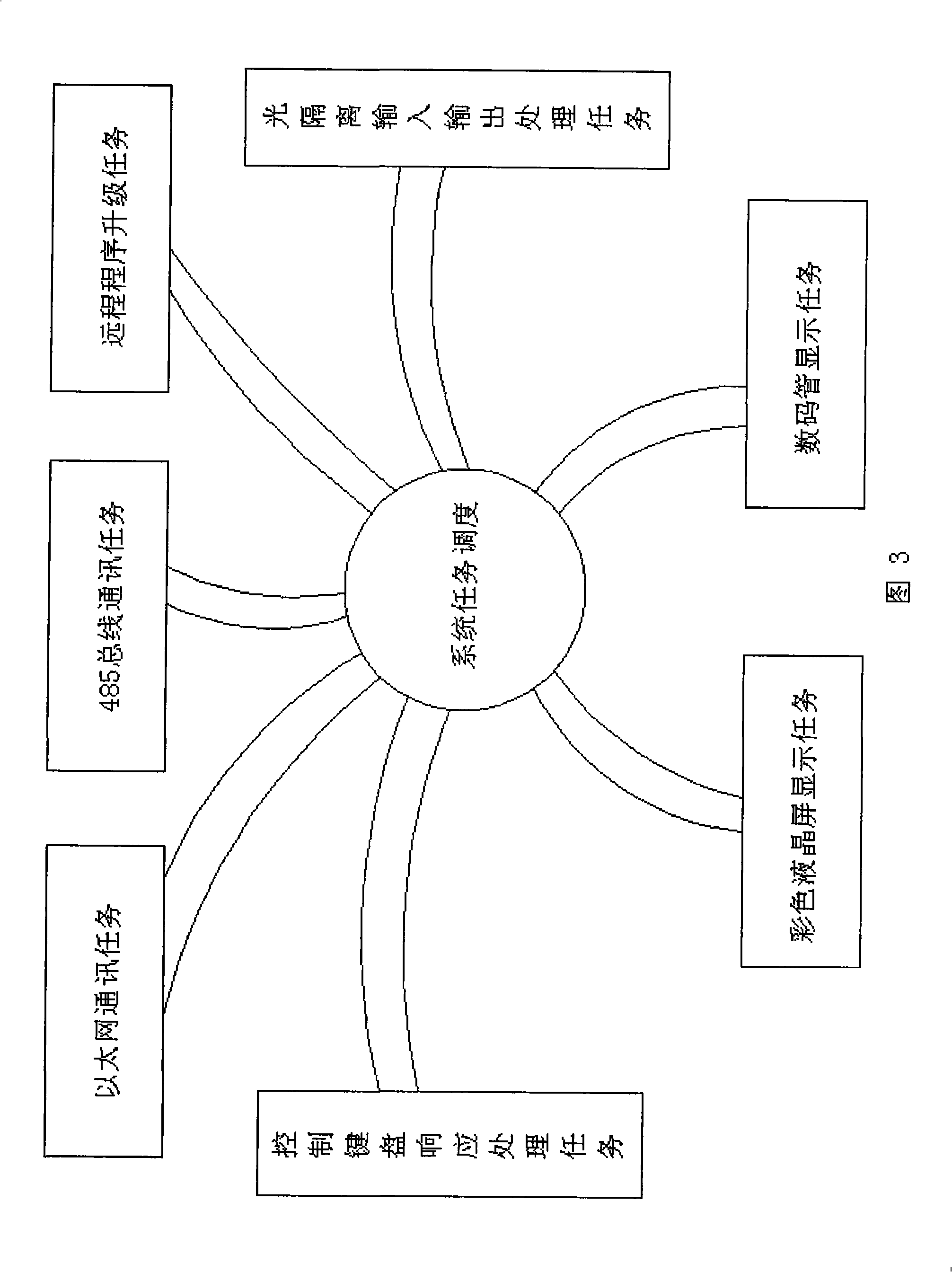

[0034] Referring to Figure 1, the electrical control system of the printing machine ink supply control system adopts a dedicated control computer and a multi-layer embedded control system. The special control computer is equipped with special control software, which realizes remote monitoring, diagnosis and maintenance through the internet, and realizes remote updating of each control layer program of the multi-layer structure embedded system. Figure 12 It is a flow chart for the local implementation of the remote update of each control layer program of the multi-layer structure embedded system. Ethernet communication is used between the dedicated control computer and the multi-layer embedded system to monitor and control the multi-layer embedded system in real time, to realize initialization, zero point adjustment, ink volume adjustment in the ink area, mechanical gap compensation adjustment, status query, Fault monitoring and diagnosis, printing ink volume preset and other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com