Full size ring type parts quenching equipment

A quenching equipment and full-scale technology, applied in the field of quenching equipment for full-scale snare parts, to ensure normal work, reduce the difficulty of processing and assembly, and ensure the accuracy of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

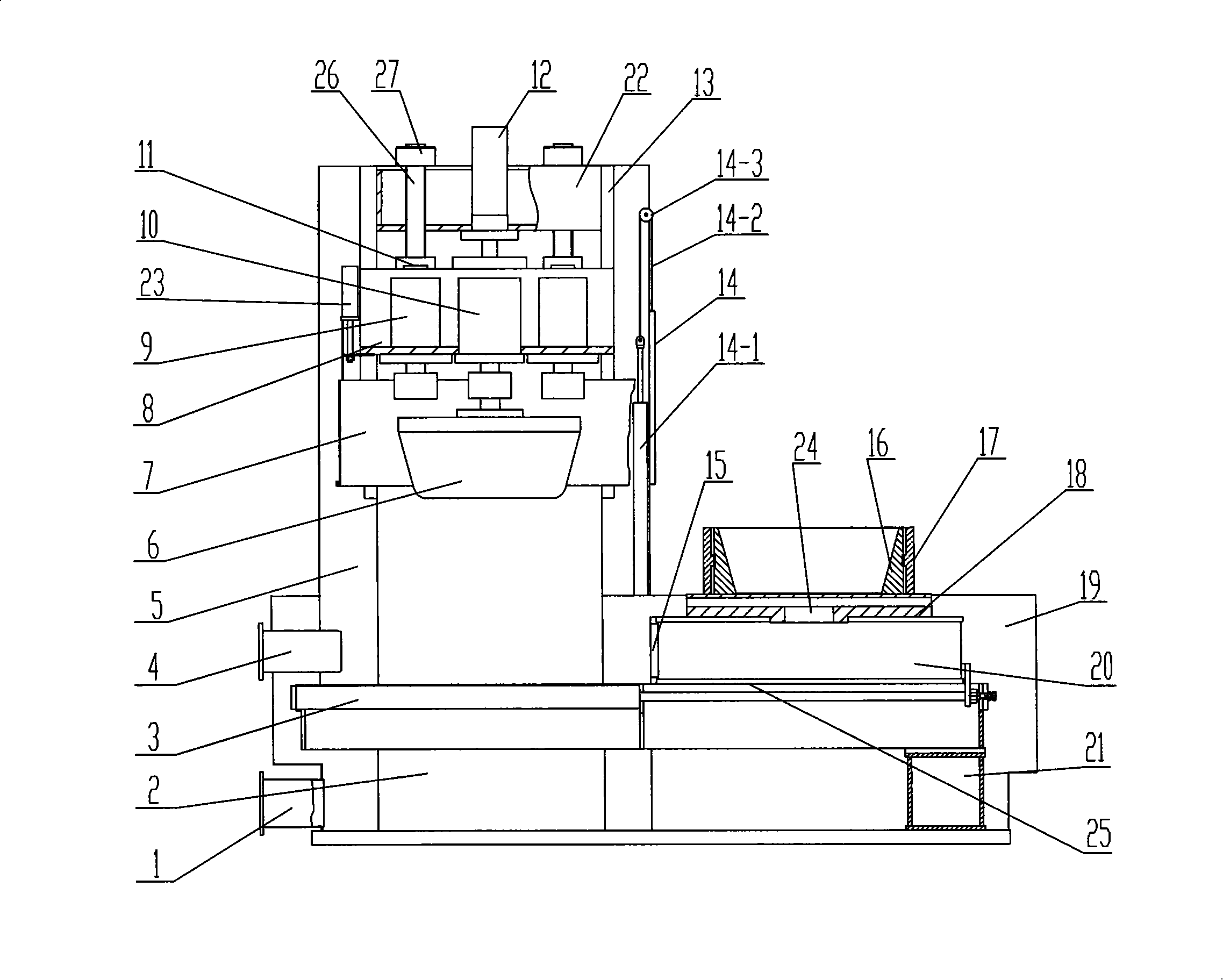

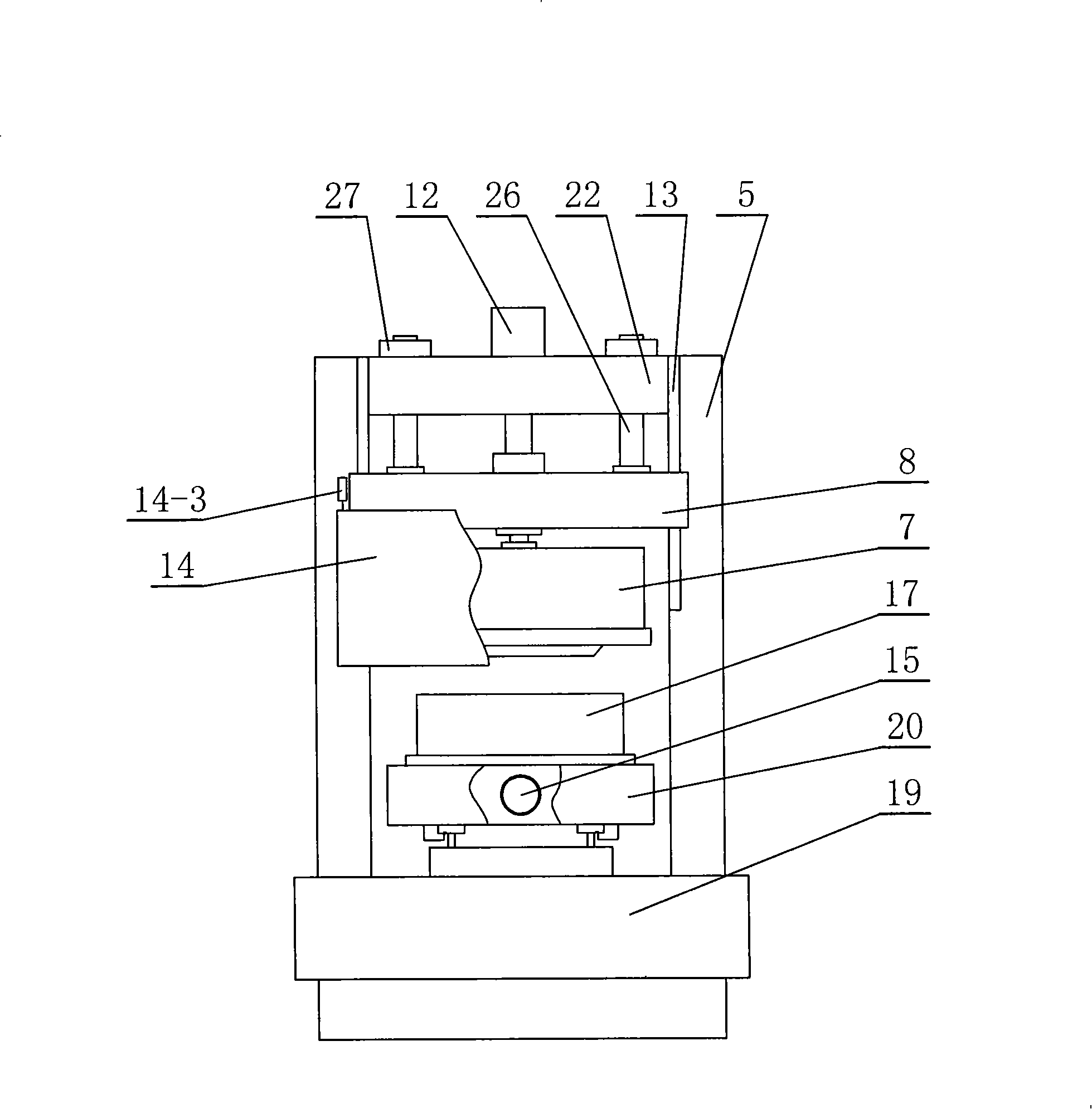

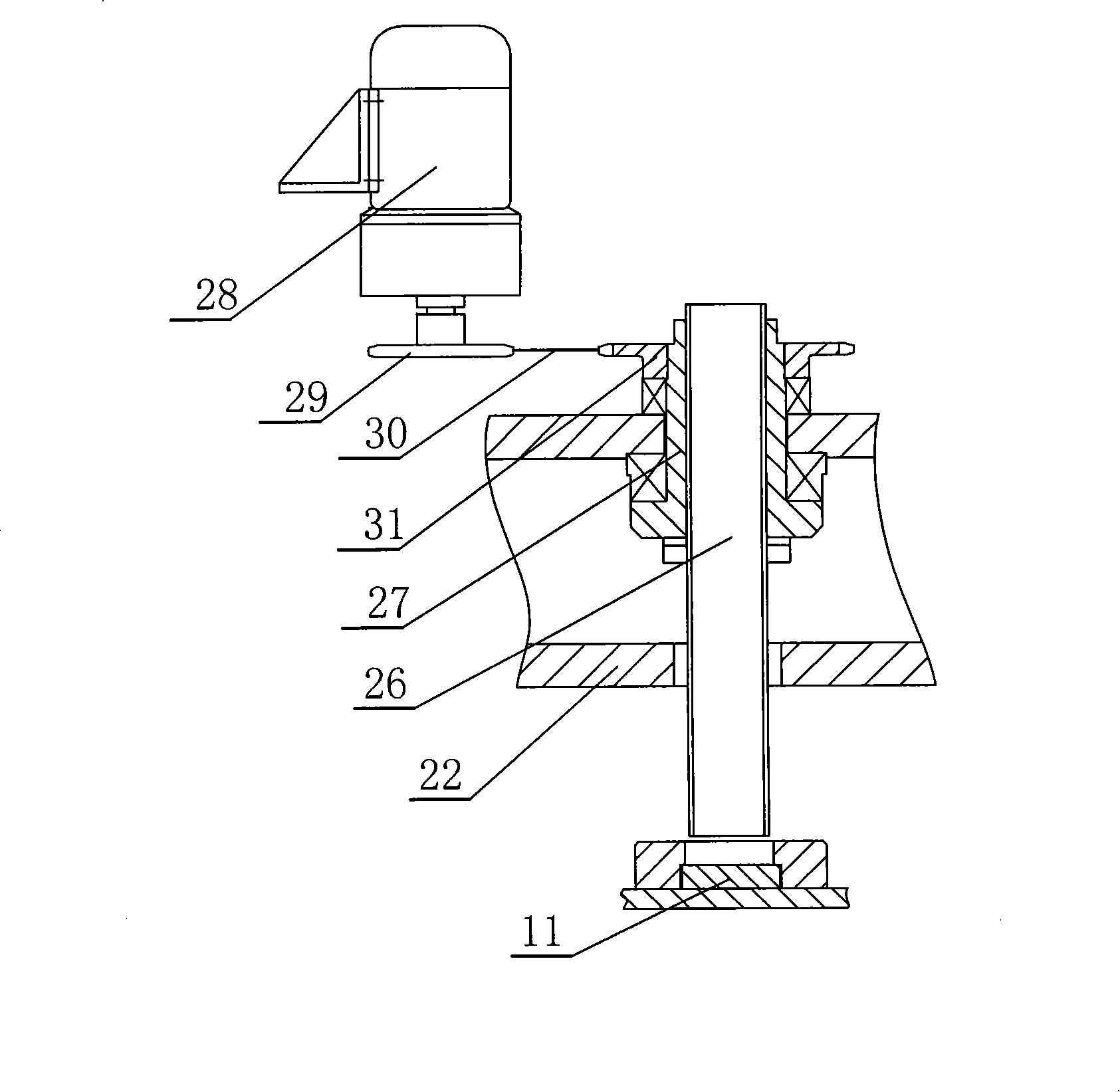

[0019] figure 1 , 2 , 3, 1-oil return port, 2-base, 3-table mobile cylinder, 4-oil inlet, 5-column, 6-upper mold, 7-telescopic oil cover, 8-moving beam, 9- Small and medium mold cylinders, 10-large mold cylinders, 11-movable inserts, 12-moving beam lifting cylinders, 13-vertical guide rails, 14-moving doors, 14-1-moving door cylinders, 14-2-wire ropes, 14- 3-fixed pulley, 15-oil inlet, 16-quenching workpiece, 17-lower mold, 18-mold bottom plate, 19-oil tank, 20-box workbench, 21-bed leg, 22-fixed beam, 23-oil Cover mobile oil cylinder, 24-oil outlet, 25-table guide rail, 26-leading screw, 27-nut, 28-nut driving motor, 29-driving sprocket, 30-chain, 31-passive sprocket.

[0020] Such as figure 1 , 2 , 3, the "door"-shaped assembly frame bed composed of the columns 5 fixedly connected to both sides of the base 2 and the fixed beam 22 fixedly installed on the top of the two columns is located in the oil tank 19 of the machine tool, and the two columns 5 are respectively insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com