Soft magnetic automobile antilocking system gear ring and method for manufacturing the same

An anti-lock braking system and soft magnetic technology, which is applied in the field of sensor signal components of the anti-lock braking system of automobiles, can solve the problems of not involving materials and difficult implementation, and achieve material saving, labor productivity improvement, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of 512078ABS ring gear:

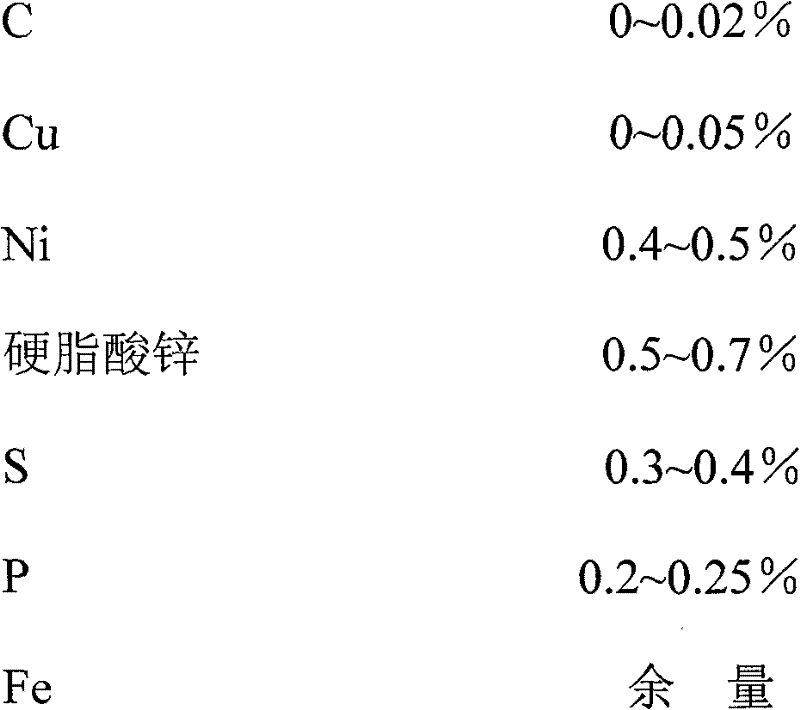

[0020] Component weight percentage formula:

[0021] Fe 98.1%

[0022] Cu 0.05%

[0023] Ni 0.5%

[0025] S 0.4%

[0026] P 0.25%

[0027] The preparation method of the above-mentioned soft magnetic automobile anti-lock braking system ring gear comprises the following steps:

[0028] After mixing the above-mentioned various materials, molding is carried out through a mold. The temperature of molding is normal temperature, and the pressure of molding is 25Mpa. After the product blank is formed, it is sintered and formed. The sintering temperature is 1130°C, preferably 1050°C, and the sintering time is 13 hours. Then carry out repressing through the plastic mold to improve its compactness and dimensional accuracy, and then use mechanical processing methods for finishing, and finally apply Dacromet coating to the product to obtain the finished product.

[0029] Required materials: (blank) outer diamet...

Embodiment 2

[0031] The preparation of 512078ABS ring gear: structure is the same as embodiment 1.

[0032] Component weight percentage formula:

[0033] Fe 99.0%

[0034] C 0.02%

[0035] Cu 0%

[0036] Ni 0.4%

[0038] S 0.3%

[0039] P 0.21%

[0040] The above-mentioned method for preparing the ring gear of the soft magnetic automobile anti-lock braking system comprises the following steps in turn:

[0041] After mixing the above-mentioned various materials, molding is carried out through a mold. The temperature of molding is normal temperature, and the pressure of molding is 7Mpa. After the product blank is formed, it is sintered and formed. The sintering temperature is 1050 ° C, and the sintering time is 11 hours. The mold is repressed to improve its compactness and dimensional accuracy, and then the machining method is used for finishing, and finally the product is dacromet-coated to obtain the finished product.

[0042] Required materials: (blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com