Airflow leaching novel technique and equipment thereof

A new process and gas flow technology, applied in chemical instruments and methods, solvent extraction, separation methods, etc., can solve the problems of separation technology difficulties, increased equipment investment and production costs, and difficult application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

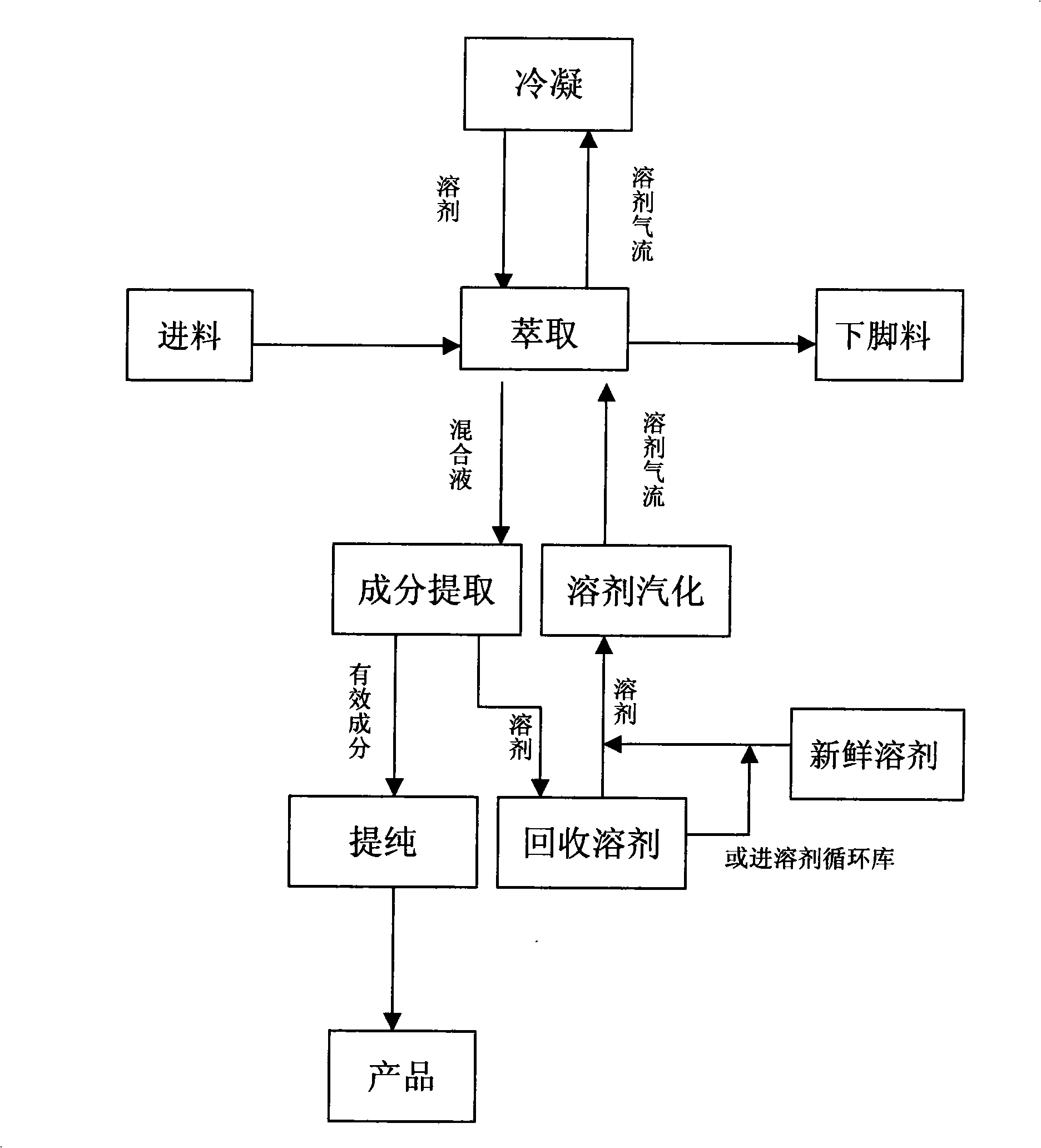

[0008] combine figure 1 , a new airflow leaching process consists of the following steps: firstly, the selected solvent is measured and stored according to a certain material-solubility ratio, and then the solvent is heated to vaporize the solvent into an airflow according to the specified vaporization rate, and then the solvent airflow is introduced into the room temperature In the solid raw material, the solvent gas flow is fully contacted and mixed with the solid raw material. At this time, the temperature of the solvent gas flow will drop and condense into liquid droplets, and the active ingredient will be dissolved to form a mixed solution of the solvent and the active ingredient. The solvent mixture of the active ingredient is separated, and then the active ingredient in the solvent mixture is extracted and the solvent is recovered. The main process parameters that affect airflow leaching are: material-solubility ratio, vaporization speed, mixed liquid concentration, sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com