Method for testing strength of diamond polyamide warp knitting net sheet for net cage

A technology of polyamide and diamond-shaped nets, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, strength characteristics, etc., can solve the difficulty of selecting net materials for net cages and restrict the sustainable and healthy development of fishing and fishery engineering , Inconsistencies in the quality indicators between the manufacturer and the user

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

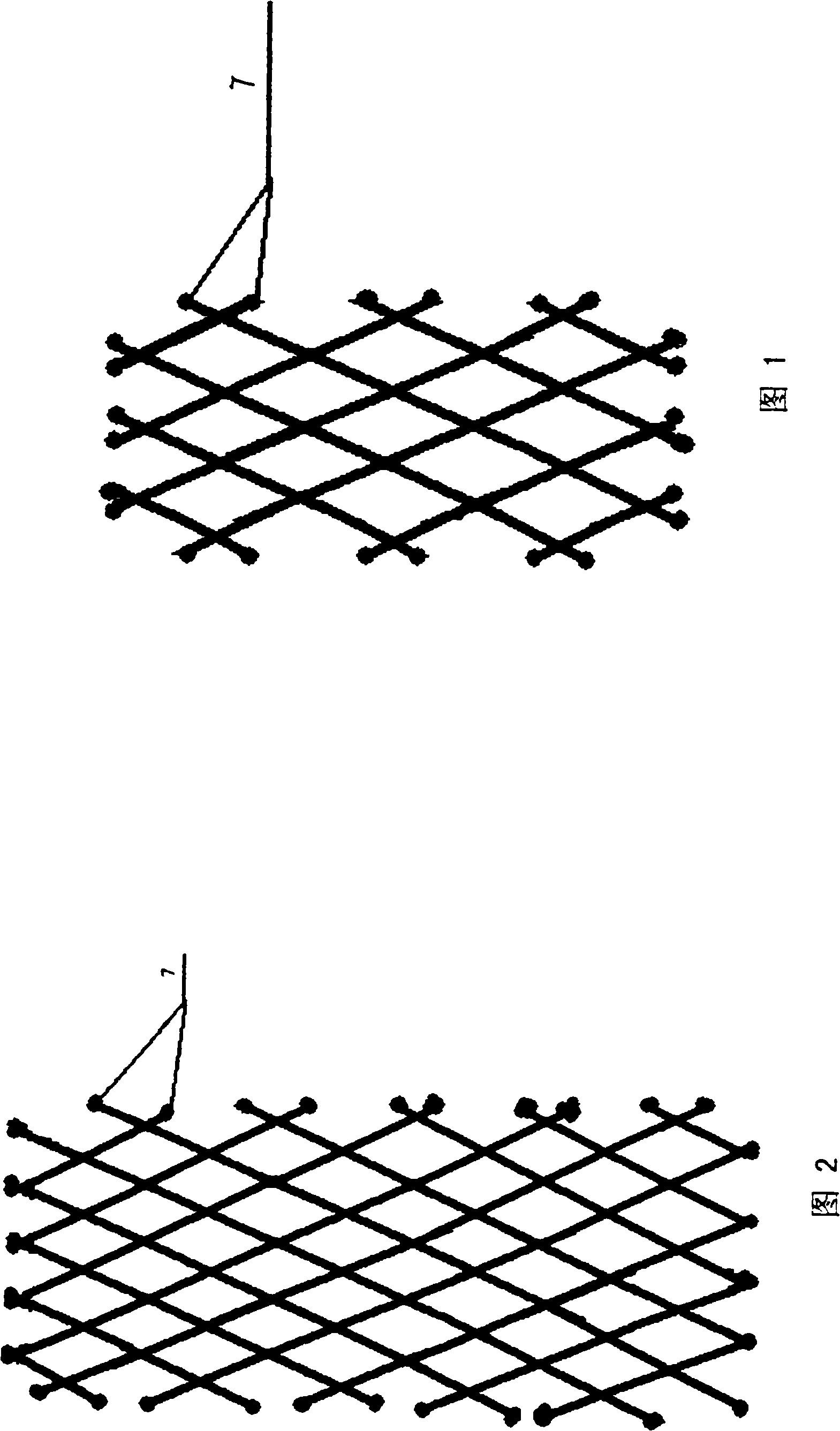

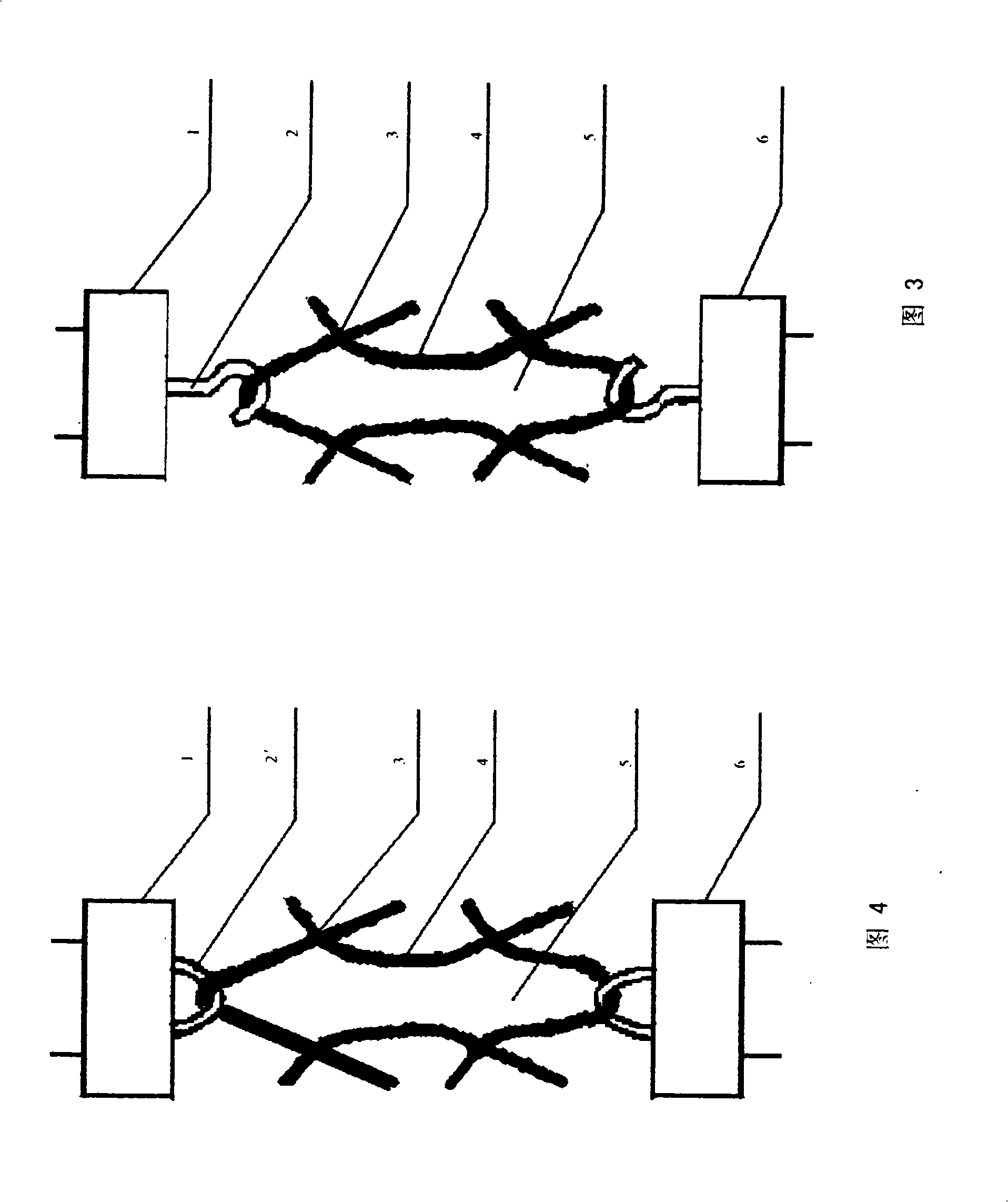

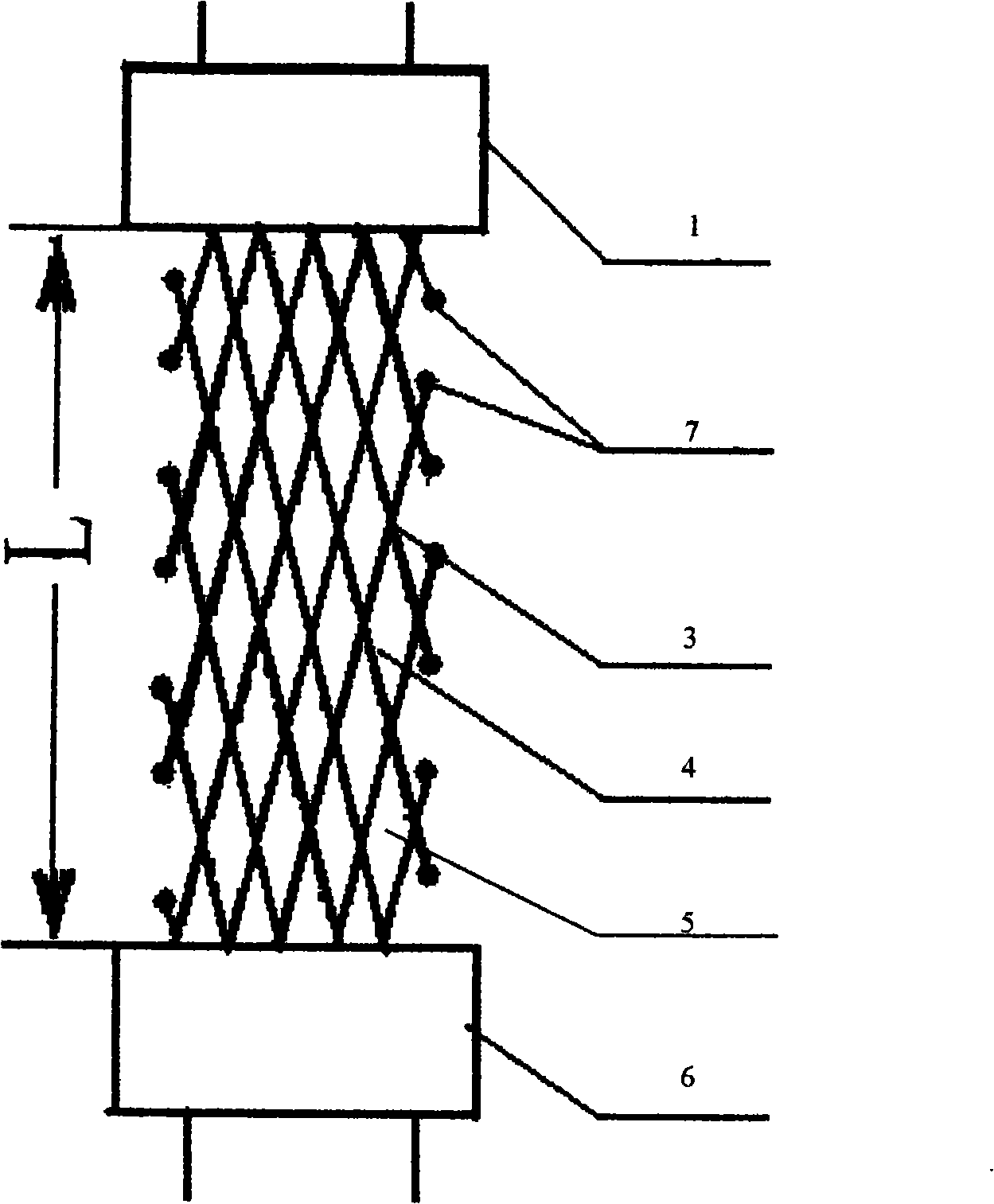

[0011] The atmospheric conditions, sampling and sample processing, test condition, test mode, data processing and result expression that influence net cage polyamide warp-knitted mesh strength test result with rhombus mesh, describe in detail the best way to implement the present invention:

[0012] During the mesh strength test of the mesh polyamide warp-knitted mesh with diamond mesh for the cage, the atmospheric conditions in the laboratory were controlled at temperature (20±3)°C and humidity (65±3)%.

[0013] Samples are obtained from various parts of the mesh edge more than 10 meshes away. Continuous sampling in the direction in which the sample is stretched is not allowed during the same project test. However, when cutting dry and wet samples at the same time, it must be The direction in which the sample is stretched is to cut two samples continuously each time, so that each pair of tensile breaking strength test is carried out on the sample containing the same yarn, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com