Method for measuring iron ore crystal water content

A determination method and technology of crystal water, applied in the field of detection, can solve the problems of complex experimental equipment, burning loss analysis, high cost, and achieve the effect of accurate experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1. Take the ore sample A and put it into an oven for baking, the baking temperature is 100° C., and the baking time is 180 minutes. After taking it out, it is pulverized and sieved to obtain particle size samples.

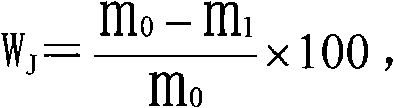

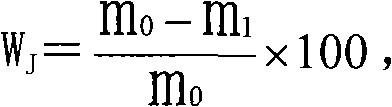

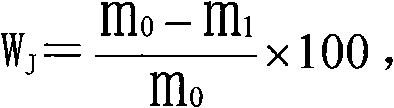

[0019] Weigh 500g soil and 0.1g sample, record it as m 0 , put the sample into the reaction tube, cover the upper cover of the reaction tube tightly, and then put the reaction tube into the constant temperature zone of the heating furnace. The heating rate is 20°C / min. In order to prevent the re-oxidation of ferrous iron in the ore, nitrogen gas is supplied to the reaction tube at a flow rate of 2L / min for protection. When the temperature reaches 380°C, the flow rate of nitrogen gas is increased to 10L / min. When the temperature reaches 400°C, keep the temperature constant for 60 minutes; after the constant temperature is over, take out the reaction tube from the furnace, continue to flow nitrogen into the reaction tube, the flow rate is controll...

Embodiment 2

[0024] Embodiment 2. Take the ore sample B and put it into an oven for baking, the baking temperature is 120°C, and the baking time is 100min. After taking it out, it is pulverized and sieved to obtain diameter sample.

[0025] Weigh 500g soil and 0.1g sample, record it as m 0 , put the sample into the reaction tube, cover the upper cover of the reaction tube tightly, and then put the reaction tube into the constant temperature zone of the heating furnace. The heating rate is 20°C / min. In order to prevent the ferrous iron in the ore from being re-oxidized, nitrogen gas is supplied to the reaction tube at a flow rate of 3L / min for protection. When the temperature reaches 380°C, the nitrogen flow rate is increased to 10L / min, and the temperature is maintained 120min; after the constant temperature is over, take out the reaction tube from the furnace, continue to pass nitrogen gas to the reaction tube, the flow rate is controlled at 5L / min, stop the nitrogen gas flow when the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com