Power supply switch and control device for implementing nought power consumption standby

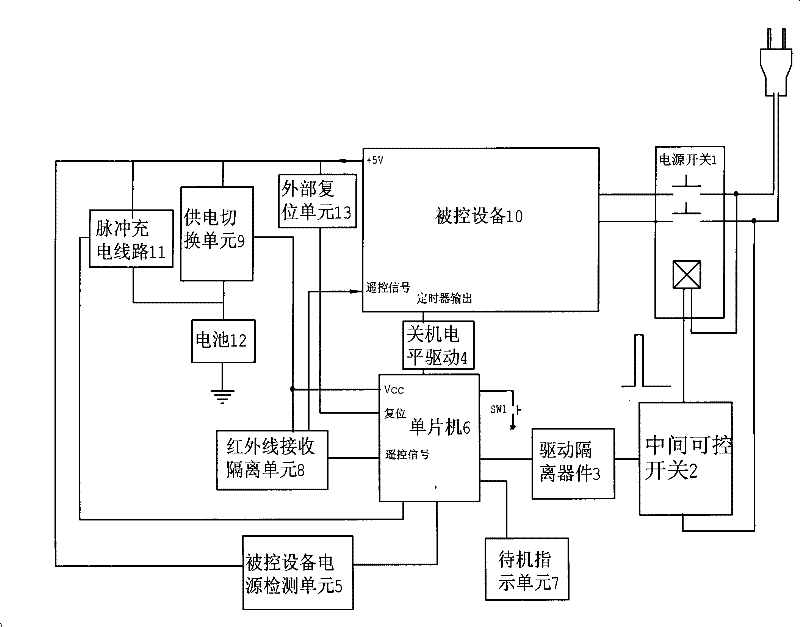

A zero-power consumption standby and control device technology, applied to computer control, power device inside the switch, program control, etc., to achieve the effect of simple structure and production process, low cost and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The action of the power switch of the present invention is described below:

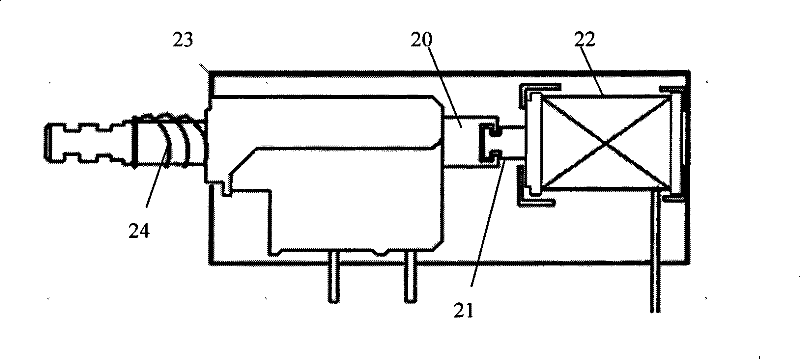

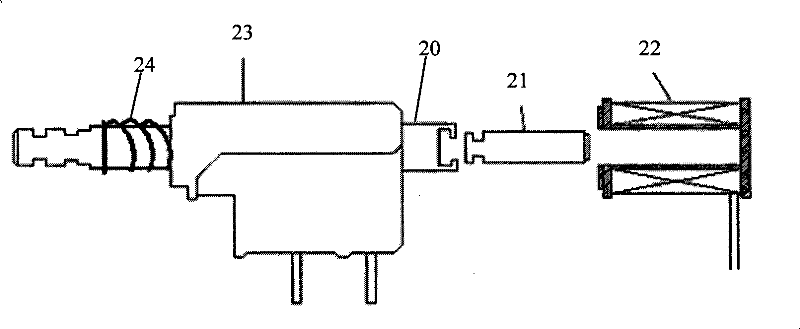

[0045] 1. Apply pulse current to make it connected: when the solenoid coil 22 is fed with pulse current, the iron core 21 will make a pull-in linear motion along the direction in which the push rod 20 is pushed in, driving the self-locking button push rod 20 Push in, the self-locking shrapnel locks the switch in the closed position, and the switch contacts remain connected after the pulse current ends;

[0046] 2. Apply pulse current to make it disconnect: when the solenoid coil 22 is fed with pulse current, the iron core 21 makes a pull-in linear motion along the pushing direction of the push rod 20, driving the self-locking button push rod 20 Push in, the self-locking shrapnel locks the switch in the off position, and the switch contacts remain open after the pulse current ends.

[0047] The above operation process is similar to manually pressing the push rod 20. After the power switch is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com