Superfine denier polyamide short fibre and producing method thereof

A production method and polyamide technology, applied in fiber processing, conjugated synthetic polymer artificial filament, filament/thread forming, etc., can solve problems such as unstable physical performance indicators, inability to form sea-island structures, and organic matter discharge environment , to achieve the effects of easy dyeing, stable structure, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

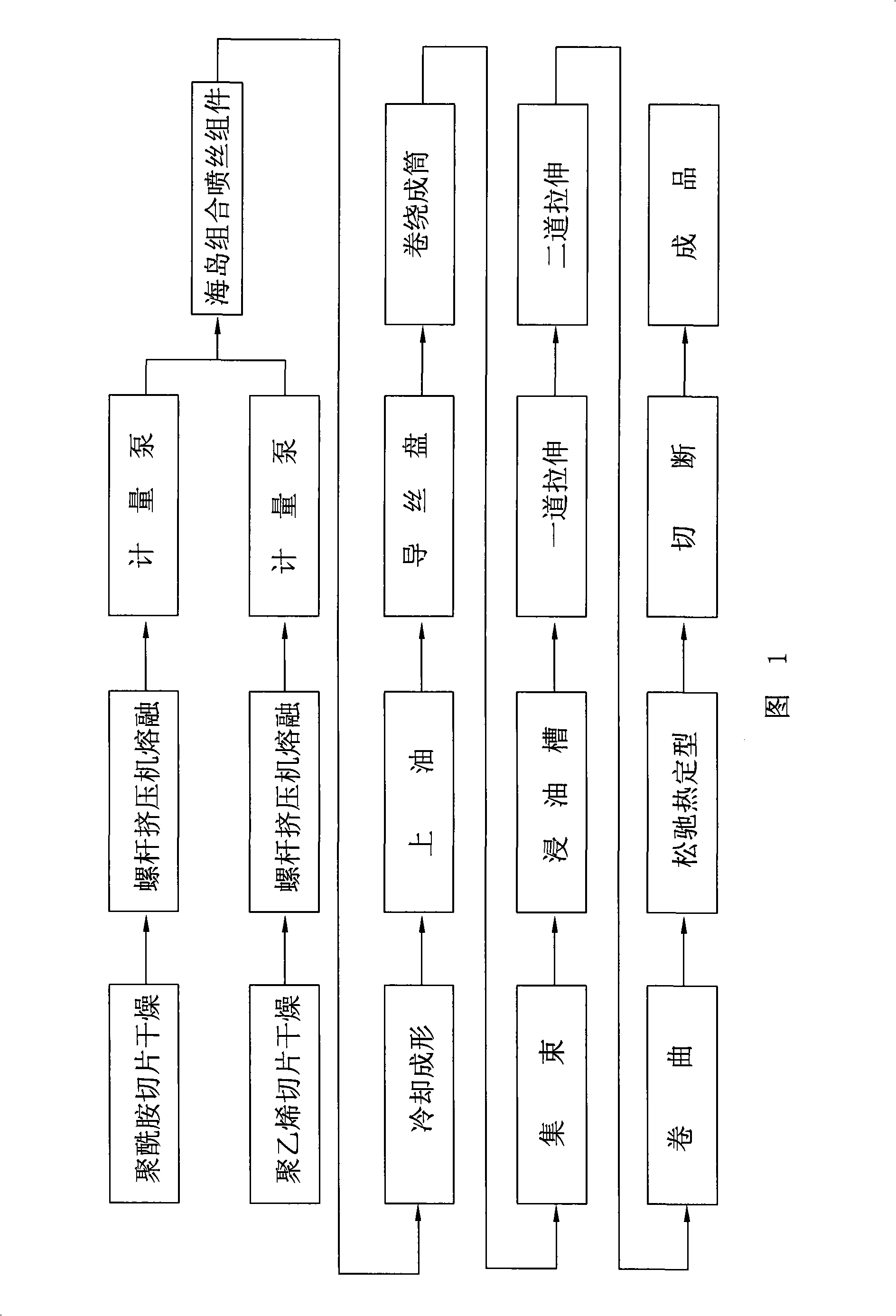

Method used

Image

Examples

Embodiment 1

[0076] PA6 / LDPE (MI=50) spinning process

[0077] The PA6 pump supply is 13.5g / min, the melt spinning temperature is 220-270°C, the screw speed is 12r / min, and the screw pressure is 70kg / cm 3 .

[0078] LDPE pump supply is 9.56g / min, melt spinning temperature is 170-275°C, screw speed is 21-22r / min, screw pressure is 52-62kg / cm 2 .

[0079] The spinning speed is 300m / min. After the spinning is normal, continue to increase the spinning speed to 600m / min and 800m / min to wind smoothly. Fuzz appears when the spinning speed is increased to 900m / min, so the spinning speed should be controlled below 800m / min.

[0080] The above-mentioned winding yarn with a spinning speed of 300m / min is stretched 2.5 times, the fiber breaking strength is 2.26CN / dtex, and the breaking elongation is 145.5%. Stretched 3 times, the fiber breaking strength is 2.73CN / dtex, and the breaking elongation is 121.7%. Stretched 3.5 times, the fiber breaking strength is 3.28CN / dtex, and the breaking elongatio...

Embodiment 2

[0083] PA6 / LDPE (MI=50) spinning process

[0084] The PA6 pump supply is 13.5g / min, the melt spinning temperature is 220-270°C, the screw speed is 12r / min, and the screw pressure is 97kg / cm 3 .

[0085] LDPE pump supply is 11.5g / min, melt spinning temperature is 170-275°C, screw speed is 29r / min, screw pressure is 60kg / cm 2 .

[0086] The above spinning process stretches 3.5 times, the fiber breaking strength is 3.05CN / dtex, and the breaking elongation is 122.7%. Bundle the above coiled filaments into 40,000 deniers, pass through the oil immersion tank (the concentration of oil agent is 8-10%), enter the first and second drafting rollers for room temperature stretching, and then the filament bundles enter the crimping machine through a 70°C preheating box . The crimped tow is relaxed and shaped for 10 minutes at a drying temperature of 70-75°C by a chain plate dryer, and then cut by a cutting machine. The number of crimps is 11.5 pieces / 25mm.

Embodiment 3

[0088] PA6 / LDPE(MI=38) spinning industry sesame

[0089] The PA6 pump supply is 13g / min, the melt spinning temperature is 220-270°C, the screw speed is 12-13r / min, and the screw pressure is 67kg / cm 3 .

[0090] The LDPE pump supply rate is 8.5g / min, the melt spinning temperature is 170-275°C, and the screw speed is 29r / min. The ratio is 115.6%, the fiber PA6 content is 60%, the fiber strength is high, and the elongation is large. The product is extracted with toluene, the sea component is dissolved, and the island monofilament fineness is 0.3dtex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com