Longitudinal spiral inner fin tube

A technology of inner fins and longitudinal, applied in the field of enhanced heat transfer elements, can solve the problems of increased flow resistance, increased fin heat transfer area, fluid longitudinal flow disturbance, etc., to enhance disturbance, inhibit fouling in the tube, and enhance convective heat transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

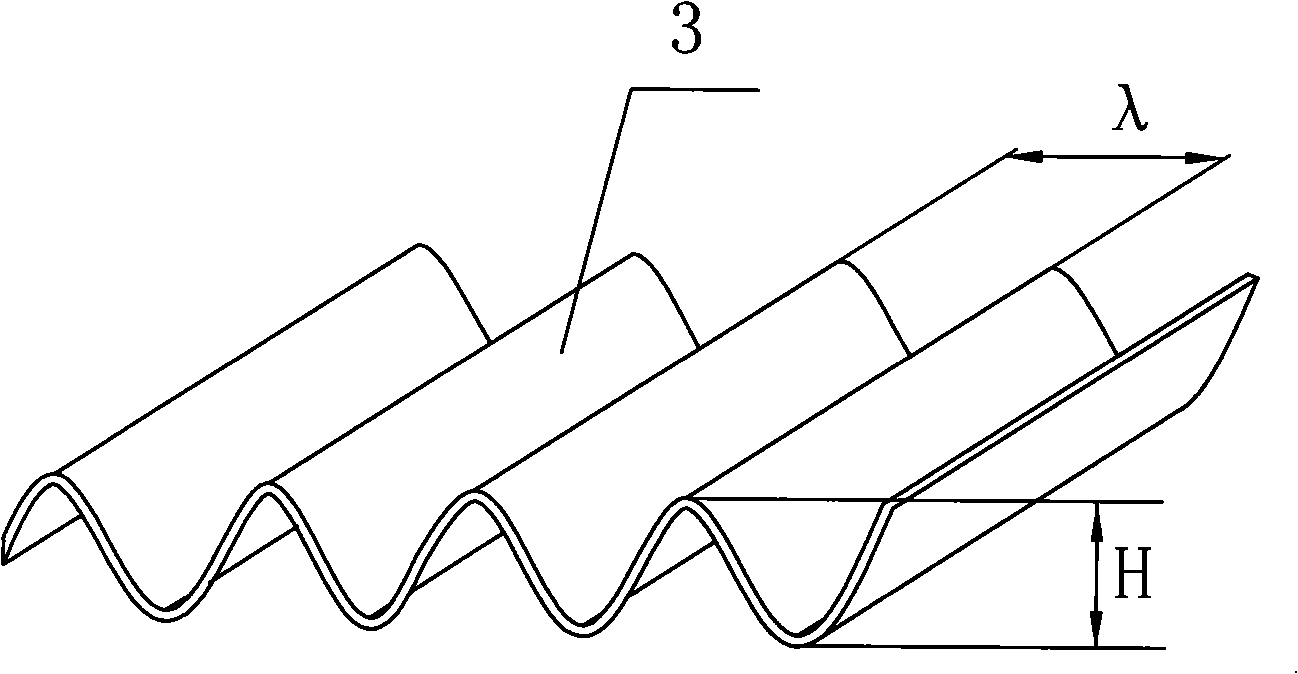

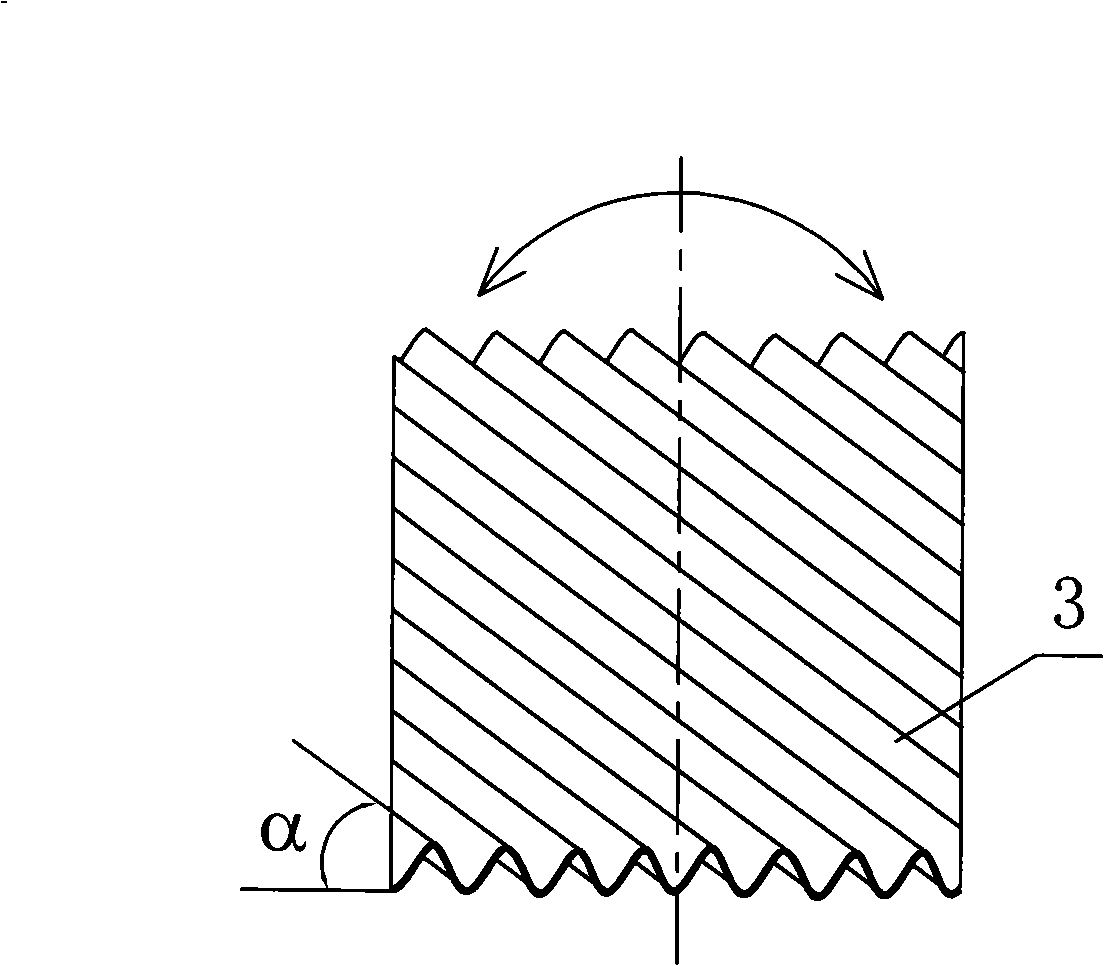

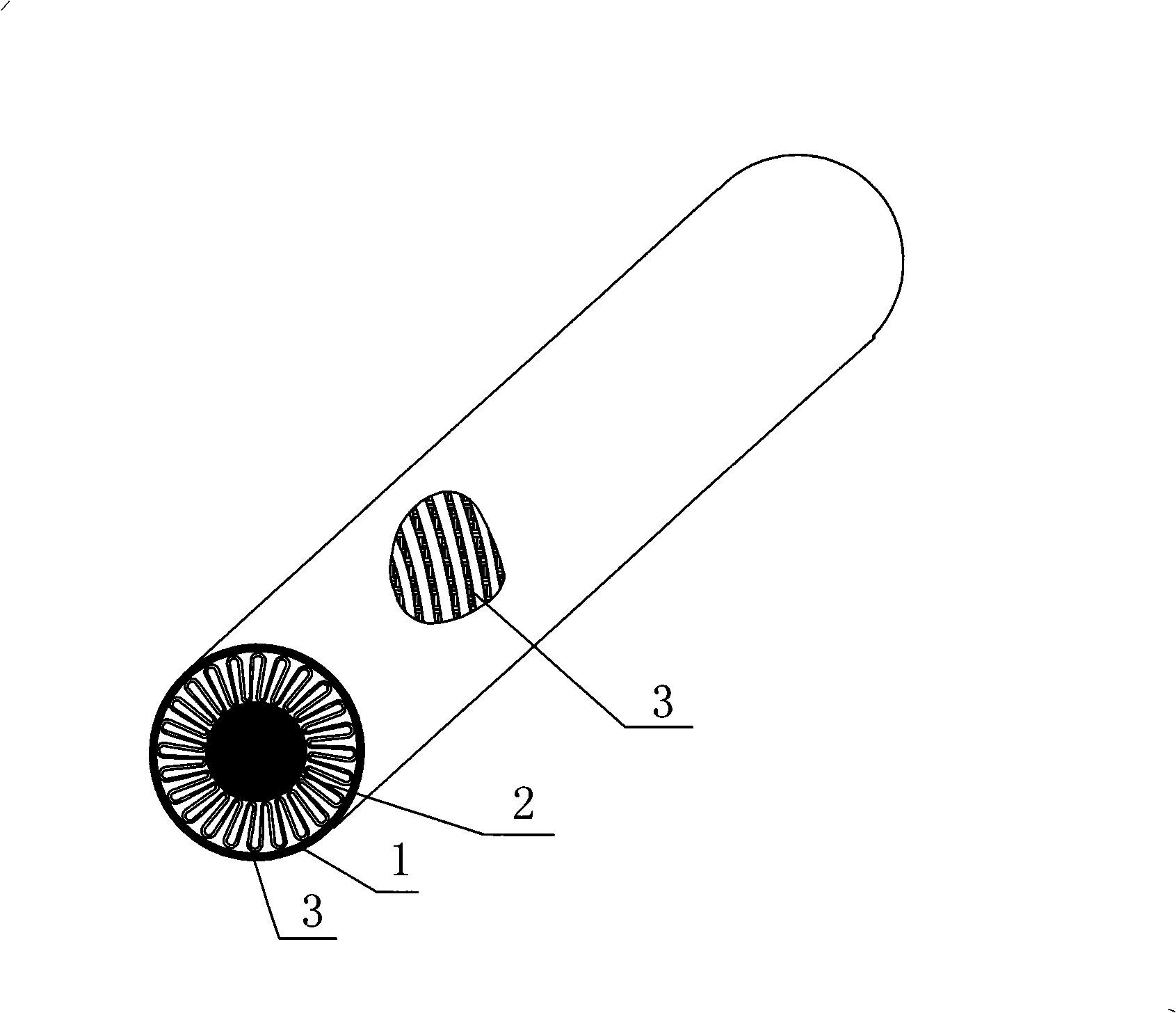

[0021] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes an outer tube 1 and a core tube 2 that are sheathed concentrically and an inner fin 3 that is embedded around the tube core between the two, and between the inner fin 3 and the outer tube 1 and the core tube 2 The connection is made by brazing. Wherein, the inner fin 3 is formed by bending a corrugated inner fin plate and forms a cylindrical longitudinal spiral inner fin tube between the outer tube 1 and the core tube 2, and the longitudinal spiral inner fin tube A plurality of longitudinal spiral circulation channels are distributed. And the included angle between the corrugated pattern of the corrugated inner fin plate and the horizontal direction is α, wherein 15°≤α≤85°. Moreover, the corrugation shape of the corrugated inner fin plate is a continuous periodic function, and the longitudinal height H of the corrugation is equal to the distance between the outer tube 1 and the core t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com