High-efficiency leaching process of nickel from laterite-nickel ore

A laterite nickel ore and leaching technology is applied in the field of chemical beneficiation, which can solve the problems of serious pollution, serious corrosion and low cost, and achieve the effects of reducing production cost, ensuring production efficiency and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

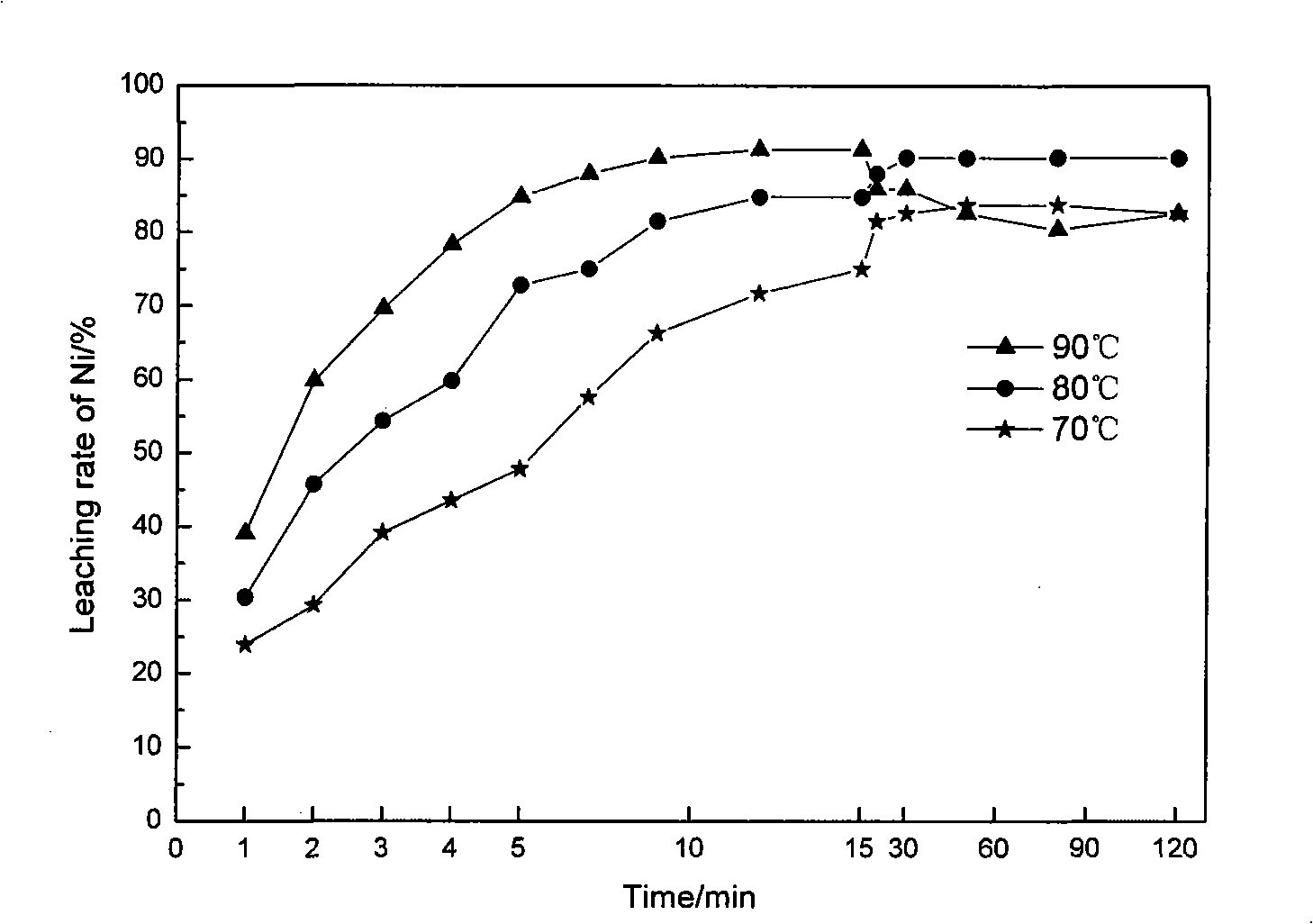

[0024] The silicate-type lateritic nickel ore is crushed and sieved to obtain leached materials with 59.9% materials<74um. Then add a certain amount of leached material into 5% (v / v) sulfuric acid solution to prepare a slurry system with a liquid-solid ratio of 3mL / g. The stirring and leaching reaction was carried out under the condition that the rotation speed of the mixer was 500 rpm, the reaction temperature was 90°C, and the reaction time was 240 minutes. After the reaction, the solid-liquid separation was carried out immediately, and the solid samples were dried, weighed, and reserved for sample preparation. The liquid was sampled for laboratory analysis, and the leaching rate of nickel was 31.2%.

Embodiment 2

[0026] The silicate-type lateritic nickel ore is crushed and sieved to obtain leached materials with 59.9% materials<74um. Then add a certain amount of leached material into 10% (v / v) sulfuric acid solution to prepare a slurry system with a liquid-solid ratio of 3mL / g. The stirring and leaching reaction was carried out under the condition that the rotation speed of the mixer was 500 rpm, the reaction temperature was 90°C, and the reaction time was 240 minutes. After the reaction, the solid-liquid separation was carried out immediately, and the solid samples were dried, weighed, and reserved for sample preparation. Liquid sampling was carried out for laboratory analysis, and the leaching rate of nickel was 68.2%.

Embodiment 3

[0028] The silicate-type lateritic nickel ore is crushed and sieved to obtain leached materials with 59.9% materials<74um. Then add a certain amount of leached material into 20% (v / v) sulfuric acid solution to prepare a pulp system with a liquid-solid ratio of 3mL / g. The stirring and leaching reaction was carried out under the condition that the rotation speed of the mixer was 500 rpm, the reaction temperature was 90°C, and the reaction time was 240 minutes. After the reaction, the solid-liquid separation was carried out immediately, and the solid samples were dried, weighed, and reserved for sample preparation. The liquid was sampled for laboratory analysis, and the leaching rate of nickel was 79.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com