Inorganic Si-Ca-Al alloy thermal insulation composite board and making method thereof

A technology of thermal insulation composite board and calcium-aluminum alloy, which is applied in thermal insulation, metal layered products, building components, etc., can solve the problem of high cost, and achieve the effect of low cost, good thermal insulation effect and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

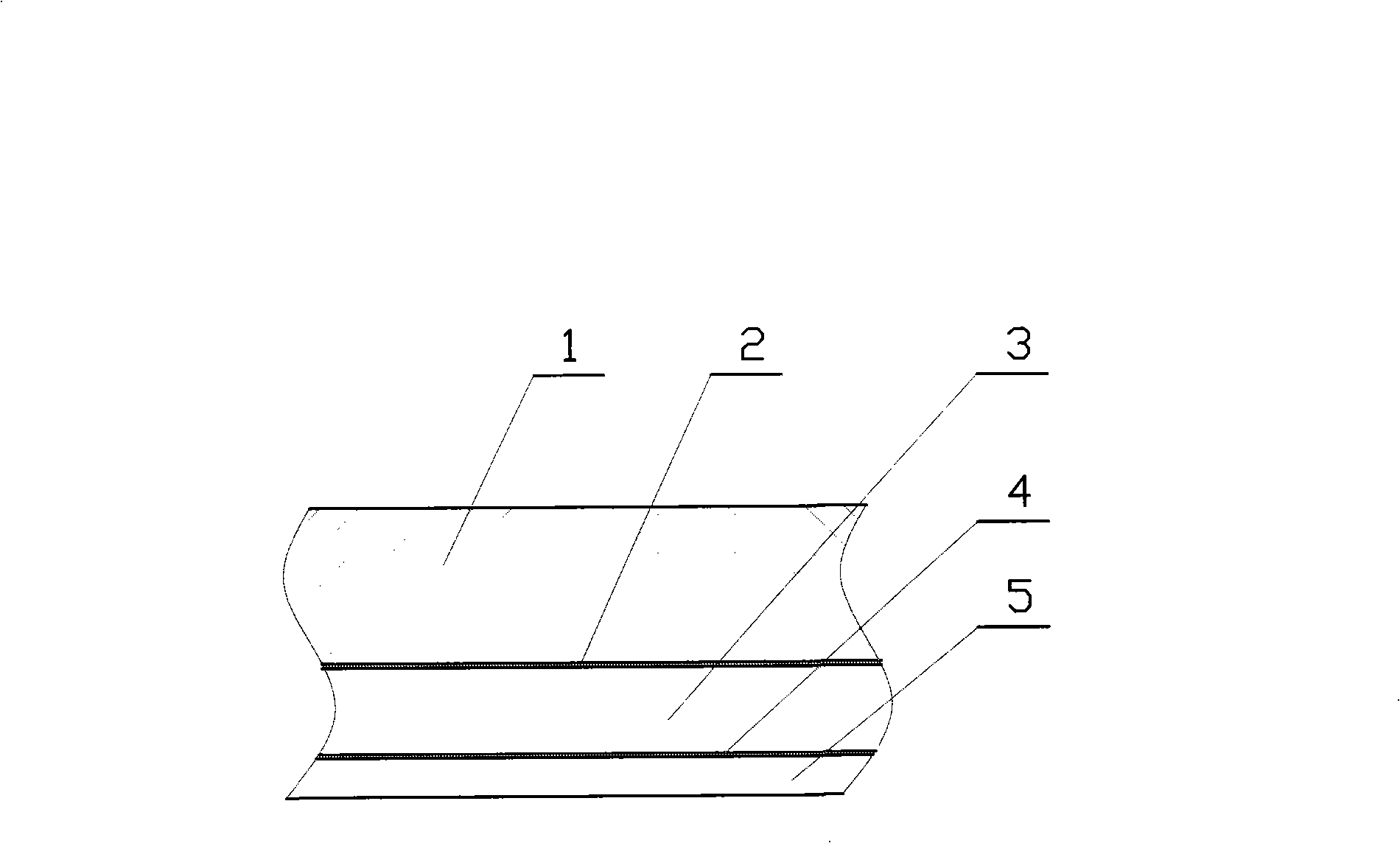

[0012] An inorganic silicon-calcium-aluminum alloy thermal insulation composite board, as shown in the figure, includes an XPS or EPS thermal insulation board 1 and an aluminum alloy thin plate 5, and an inorganic silicon-calcium is also included between the XPS or EPS thermal insulation board 1 and the aluminum alloy thin plate 5 plate 3.

[0013] Its production process includes,

[0014] 1) Paste the inorganic silicon-calcium board 3 and the aluminum alloy sheet 5 with an epoxy resin adhesive 4;

[0015] 2) The above-mentioned pasting board is pressed under the action of a cold press until the epoxy resin is completely dried to form an aluminum-calcium composite board;

[0016] 3) After taking out the aluminum-calcium composite board, spray water-based neoprene 2 on the bottom surface of the silicon-calcium composite board and the surface of the EPS or XPS board to compound the insulation board to form an insulation composite board;

[0017] 4) Put the thermal insulation c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com