Non-positive clamping connection and method for its production

A technology for clamping connections and clamping elements, applied in the direction of connection members, friction-clamped detachable fasteners, connections, etc., which can solve the problem of reduced friction coefficient, surface roughness, loosening of clamped connections, and reduced coating. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

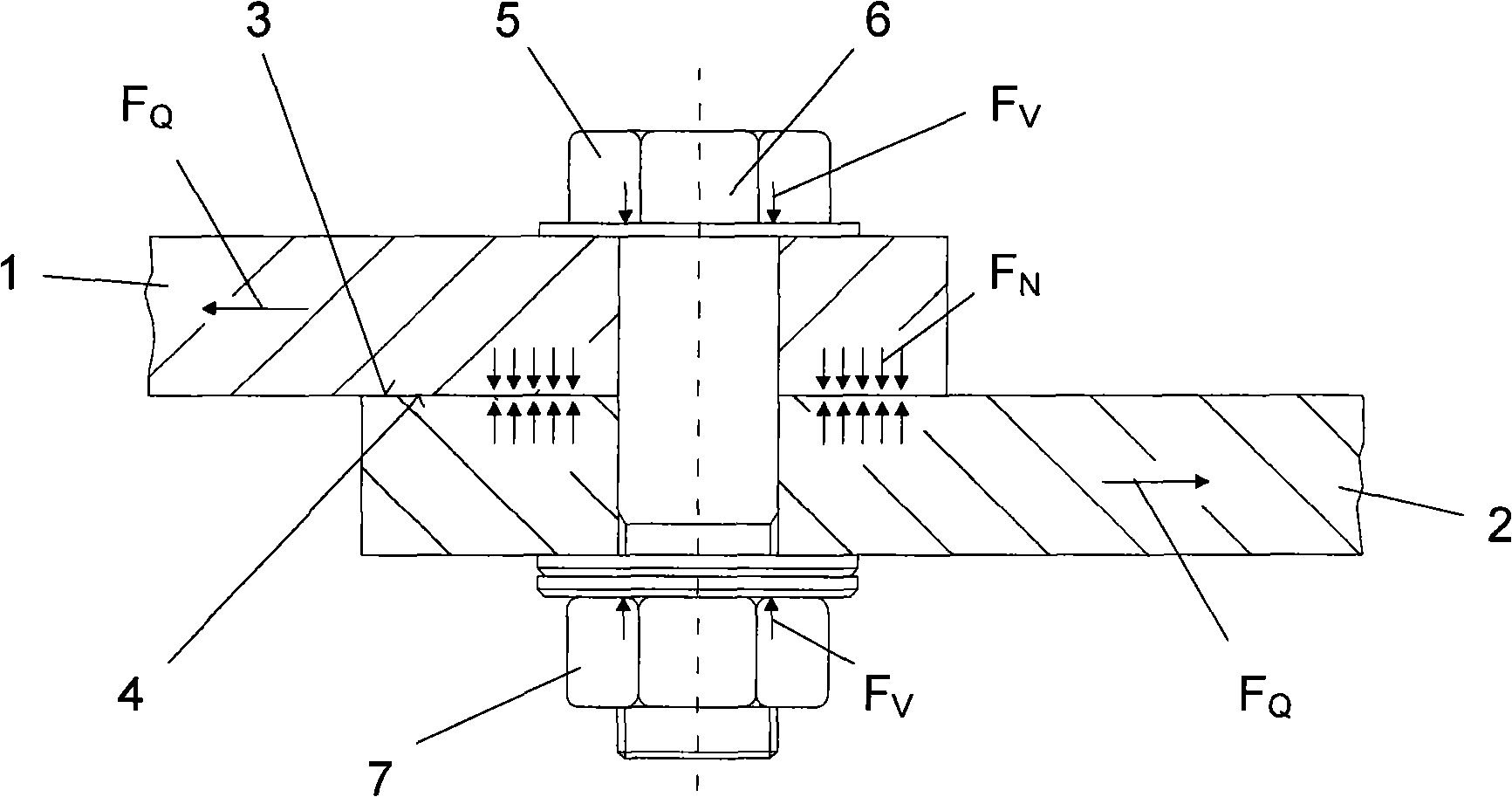

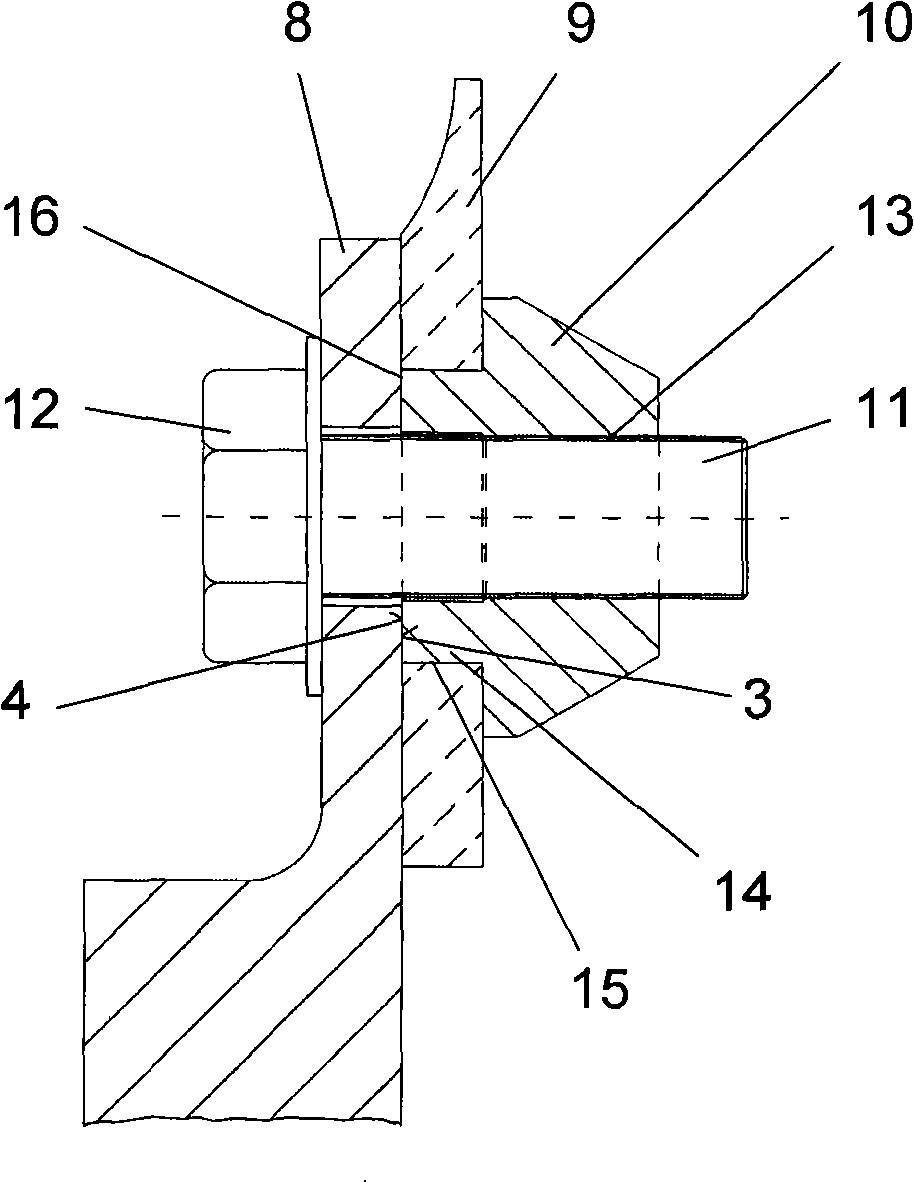

[0034] Embodiment Example 1 demonstrates a method for transmitting a transverse force F between two flanges 1 and 2 Q Press-fit clamp connections. The two flanges 1 and 2 are pressed against each other via respective metal clamping surfaces 3 and 4 and are clamped together by a clamping element 5 , here designed as a bolt 6 with a nut 7 .

[0035] Prestress F of clamping element 5 V The selection method is to make the adhesion effect between the clamping surfaces 3 and 4 take effect, the resulting normal force F N and the transmitted lateral force F Q The following conditions:

[0036] f N ·μ>·F Q

[0037] The higher the coefficient of friction μ, the transmissible lateral force F Q bigger. Thus, according to the invention, one of the clamping surfaces 3 or 4 has an increased surface roughness compared to conventional clamping surface pairs, in order to obtain a fine surface structure comprising microreliefs and microdepressions. This structure with increased roughnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com