Heat exchanger

A heat exchanger and heat exchange tube technology, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as reducing heat exchange efficiency, low efficiency of heat exchanger use, and affecting reuse. , to reduce production costs and operating costs, improve heat exchange efficiency, and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

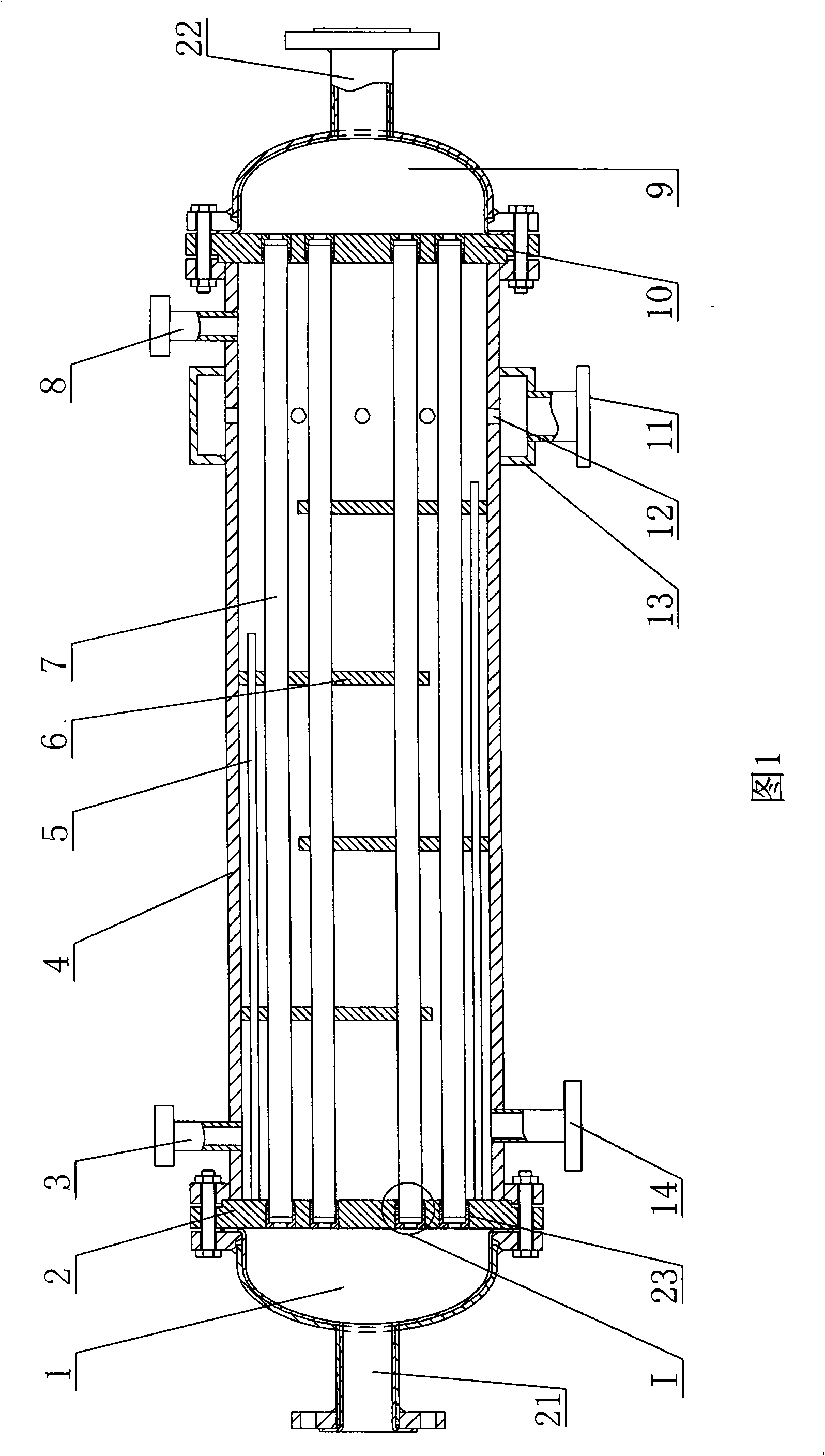

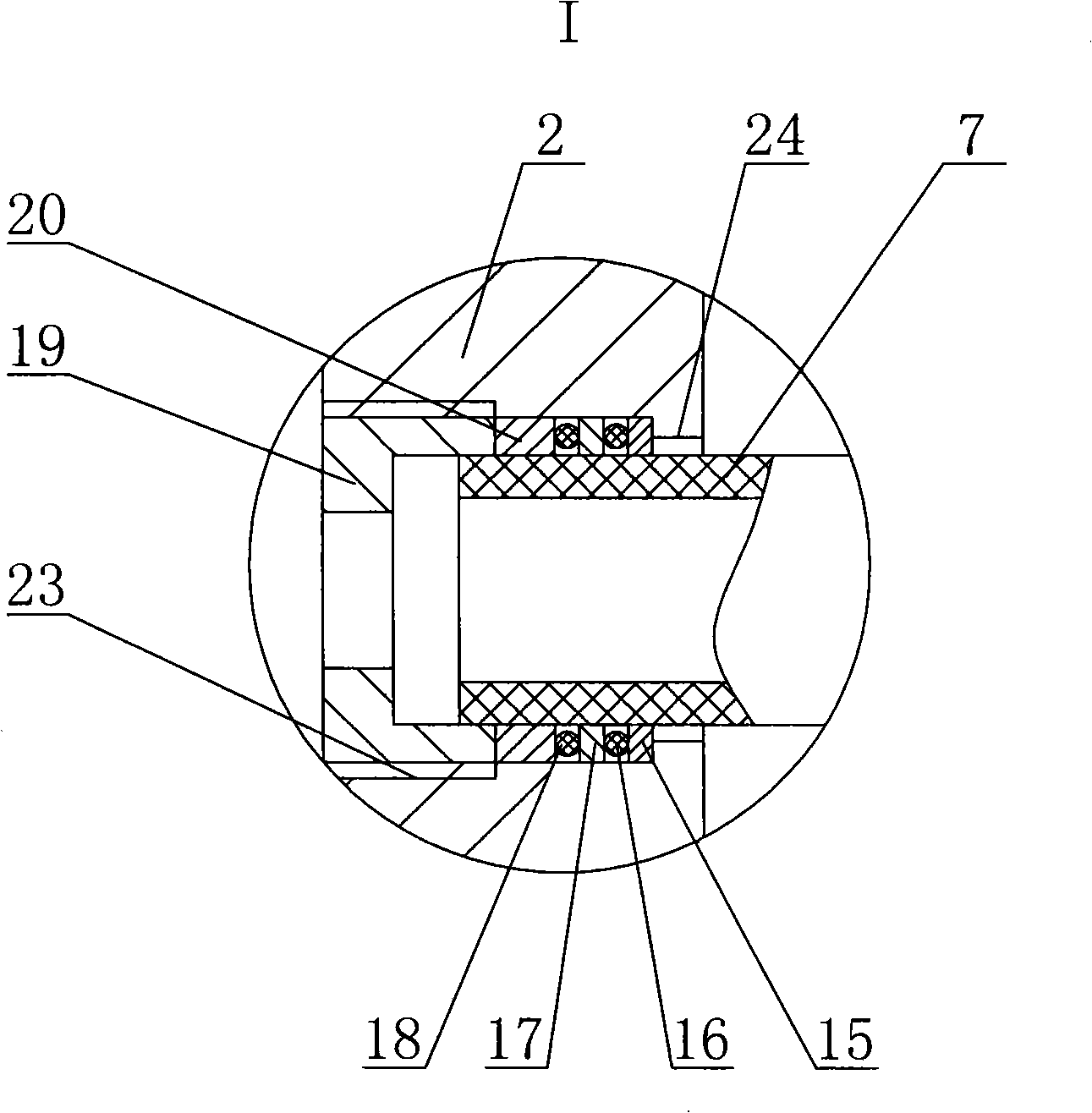

[0014] The present invention includes a tube shell 4, which is a barrel-shaped hollow structure. The tube shell 4 can be made of different materials according to the medium liquid used, such as carbon steel or stainless steel. The first tube plate 2 and the second tube plate 10 are respectively installed at both ends of the tube shell 4, the first head 1 is installed on one side of the first tube plate 2, the second head 9 is installed on the side of the second tube plate 10, and the first seal A first liquid outlet 21 is provided on the head 1 , and a second liquid outlet 22 is provided on the second head 2 . The first tube sheet 2 and the second tube sheet 10 are provided with corresponding through holes 23 , and the heat exchange tubes 7 are installed in the through holes 23 . The heat exchange tube 7 is made of silicon carbide or silicon nitride. The number of heat exchange tubes 7 is determined according to the liquid flow rate, and generally 5-10 heat exchange tubes are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com