Valve controlled sealing type golf battery and manufacturing method therefor

A golf, sealed technology, used in lead-acid batteries, final product manufacturing, lead-acid battery construction, etc., can solve the problems of acid mist pollution, electrolyte leakage, large self-discharge and other problems, achieve high hydrogen evolution overpotential, The effect of reducing internal resistance and small self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

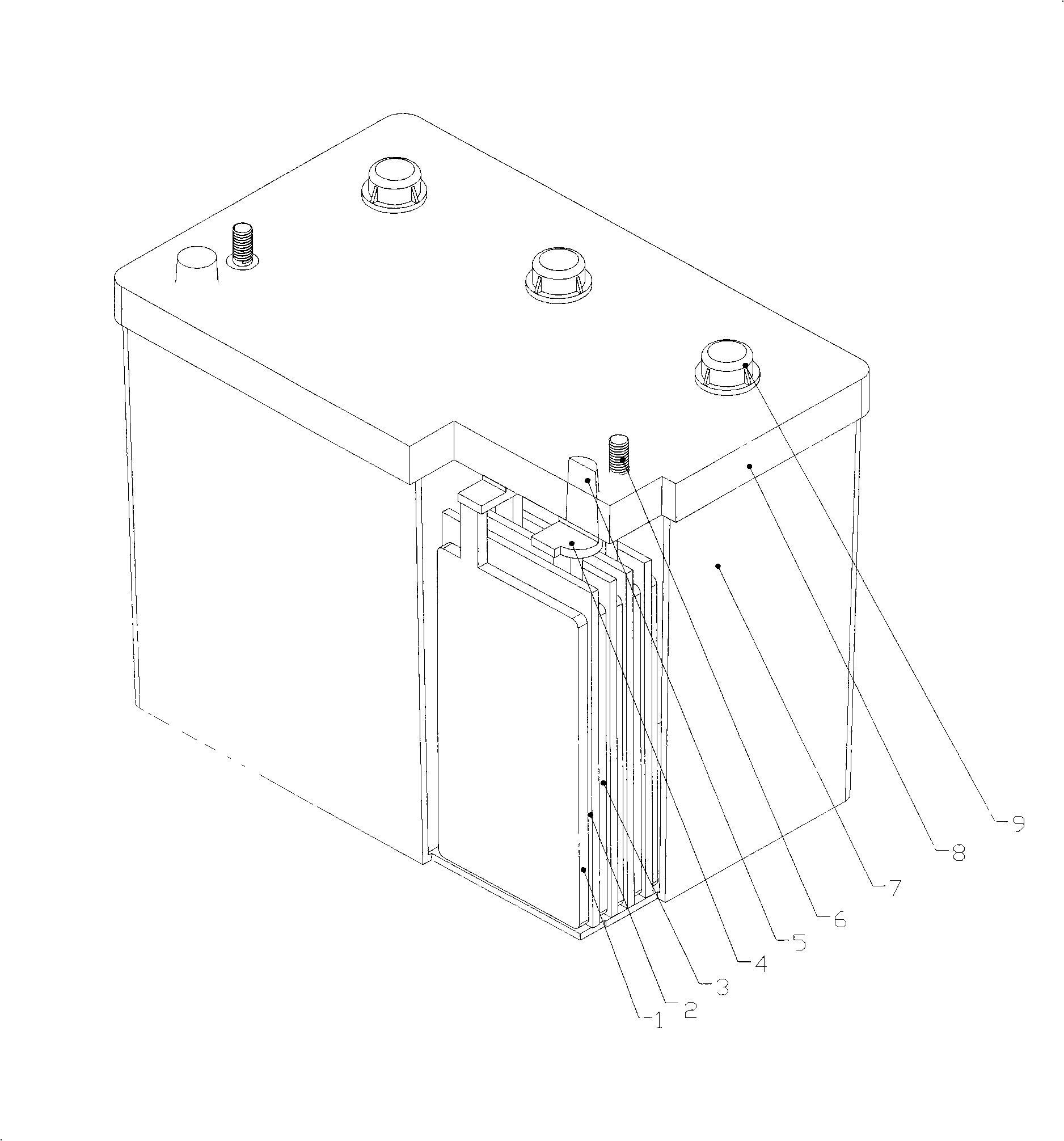

[0013] As shown in Figure 1, the golf battery is mainly composed of a battery case 7, a battery cover 8, an electrode group, an electrolyte, terminals 5, 6 and a safety valve 9, and the electrode is placed in the cavity formed by the battery case 7 and the battery cover 8. Each monomer pole group is connected in series through wall welding. The monomer pole group is composed of positive and negative plates 1, 3 and AGM separator 2. The battery is tightly assembled, and the battery cover 8 is provided with Pole terminal 5, screw terminal 6 and safety valve 9.

[0014] The manufacturing method of the golf battery of the present invention: at first, produce pole plate 1,3 and battery shell 7, adopt lead-calcium multi-component alloy to produce pole plate, PP plastics produce battery shell; Secondly, coat on positive and negative plate 1,3 The AGM separator 2 is assembled into pole groups according to the design requirements, and the pole groups are formed into single pole groups ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com