Multi-electrode rotary arrester switch for high-voltage impulse power source

A technology of high-voltage pulse power supply and spark gap switch, which is applied in the direction of rotary spark gap, spark gap, circuit, etc., to achieve the effect of improving stability and reliability, convenient disassembly and maintenance, and reliable opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

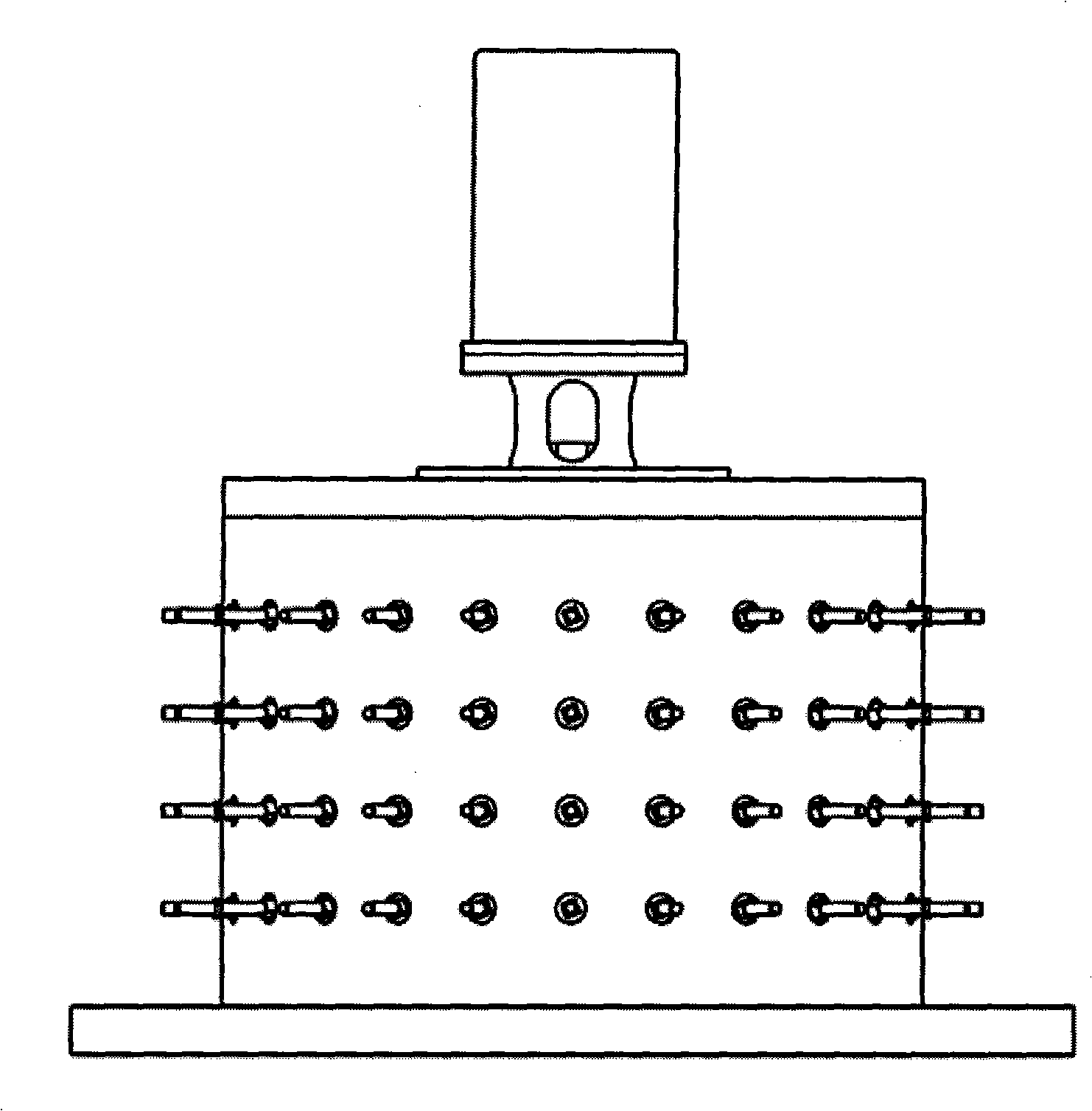

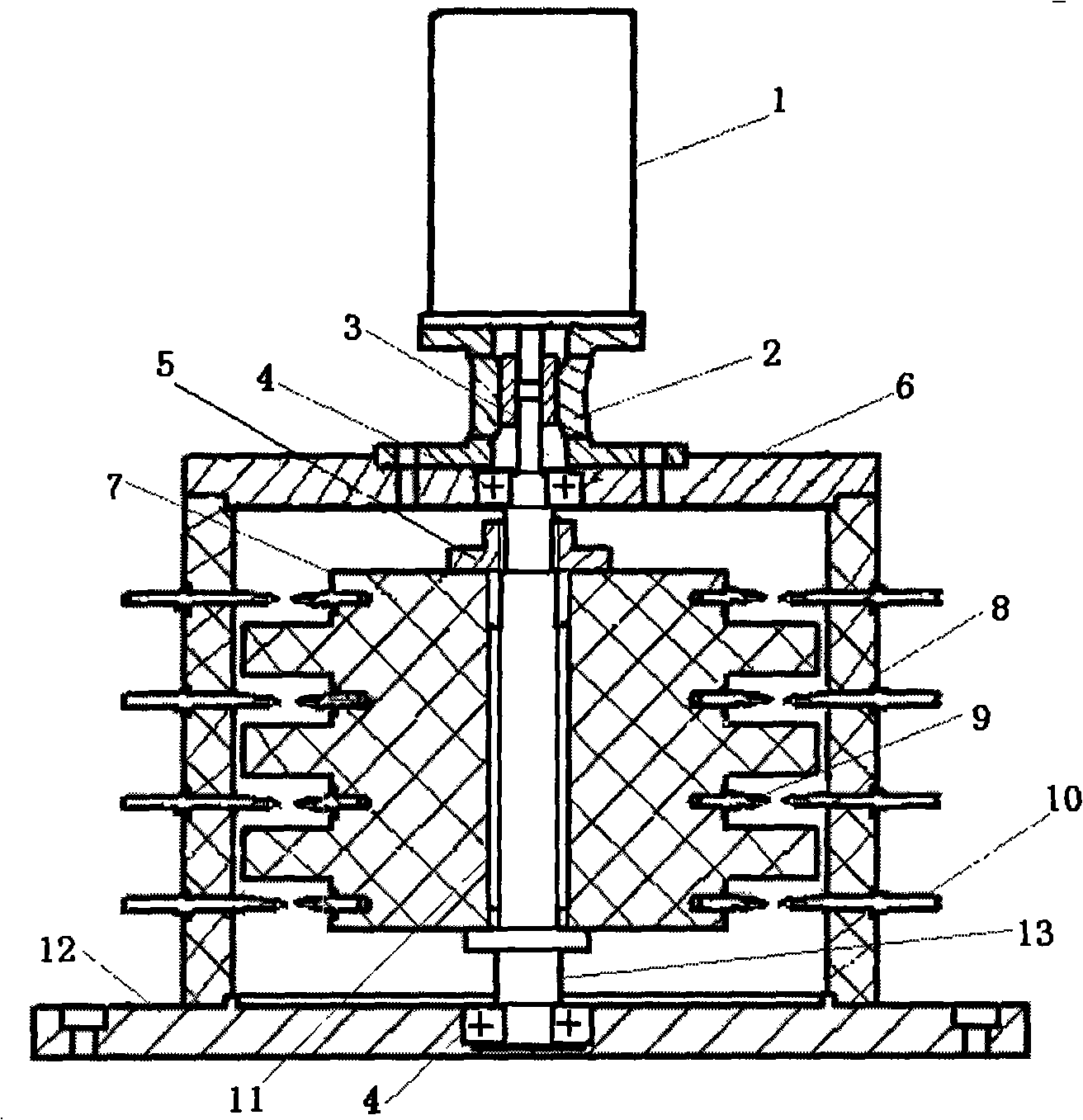

[0042]Multi-electrode rotary spark gap switch for high-voltage pulse power supply (suitable for high voltage > 20Kv, compact structure) (such as figure 1 ), the switch includes: stator 8, rotor 7, rotor needle electrode 9, stator needle electrode 10, drive motor 1, shaft 13, bearing 4, coupling 3, coupling sleeve 2, upper end cover 6, lower end cover 12.

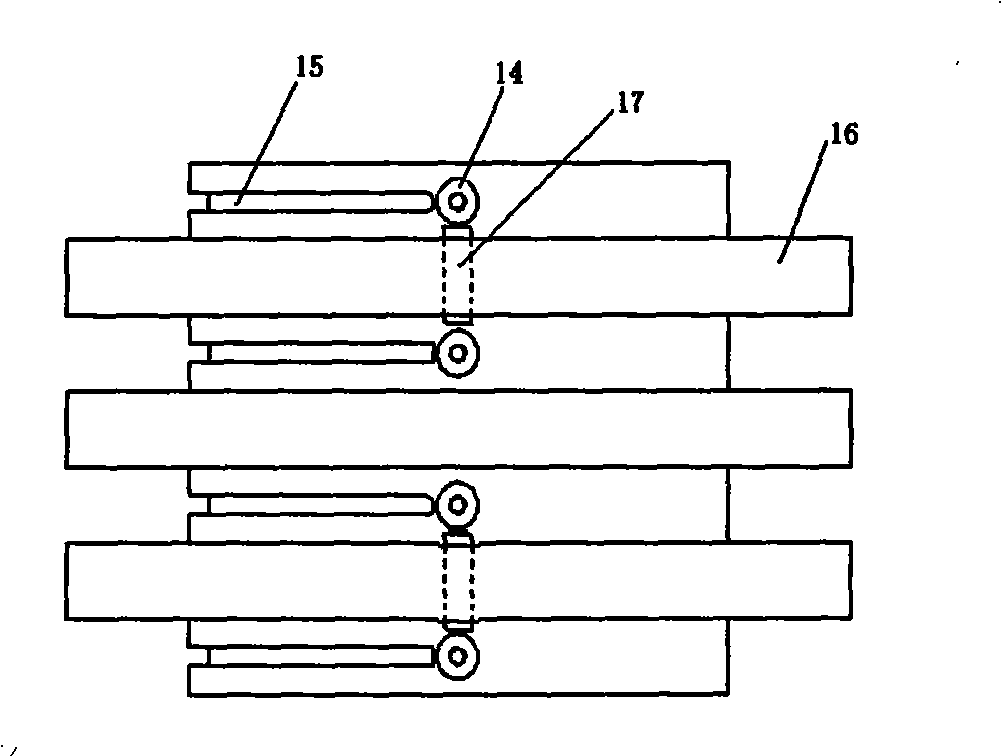

[0043] Four layers of stator needle electrodes 10 and rotor needle electrodes 9 are respectively installed on the stator 8 and the rotor 7 through screw connections. Let d be the insulation distance between the upper and lower needle electrodes of the stator. In order to ensure the reliable operation of the switch, d should satisfy d ≥ U ( kV ) 30 × 40 ( mm ) , Where U (kV) is the switch operating volta...

Embodiment 2

[0054] The four-switch multi-electrode rotary spark gap switch is suitable for high voltage < 20kV and compact structure. Its structure is the same as that of the two-switch multi-electrode rotary spark gap switch in Embodiment 1, except that the wire connection method is different.

[0055] Four layers of needle electrodes are respectively installed on the stator 8 and the rotor 7 . Let d be the insulation distance between the upper and lower needle electrodes of the stator. In order to ensure the reliable operation of the switch, d should satisfy d ≥ U ( kV ) 30 × 40 ( mm ) , Where U (kV) is the switch operating voltage.

[0056] On the stator 8, 24 stator needle electrodes 10 are evenly installed on each layer, which are divided into two groups, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com