Corrosion-protection and soil-protection method for watercraft

A ship and anti-fouling technology, which is applied in the direction of ship hull, ship construction, ship cleaning device, etc., can solve the problems of affecting long-term use effect, non-corrosion resistance, high density of metal powder, etc., so as to increase ship operation economy and reduce operation resistance , the effect of long-term use

Inactive Publication Date: 2009-01-14

DALIAN MARITIME UNIVERSITY

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Japanese patent No. 58-11564 reports that the conductive paint mixed with metal powder or conductive carbon black can be used as conductive antifouling paint under the weak current, but the metal powder has a large density and is not corrosion-resistant, and the conductive carbon black easily migrates to the surface and escapes. Into the seawater to reduce the volume conductivity, thus affecting the long-term use effect

Chinese patent 97115977.7 discloses a preparation method of conductive polyaniline anti-fouling anti-corrosion coating. This method uses cuprous oxide as an anti-fouling additive instead of producing hypochlorous acid anti-fouling through electrolysis of seawater. Although it can prevent pollution, it will destroy the ocean. ecosystem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

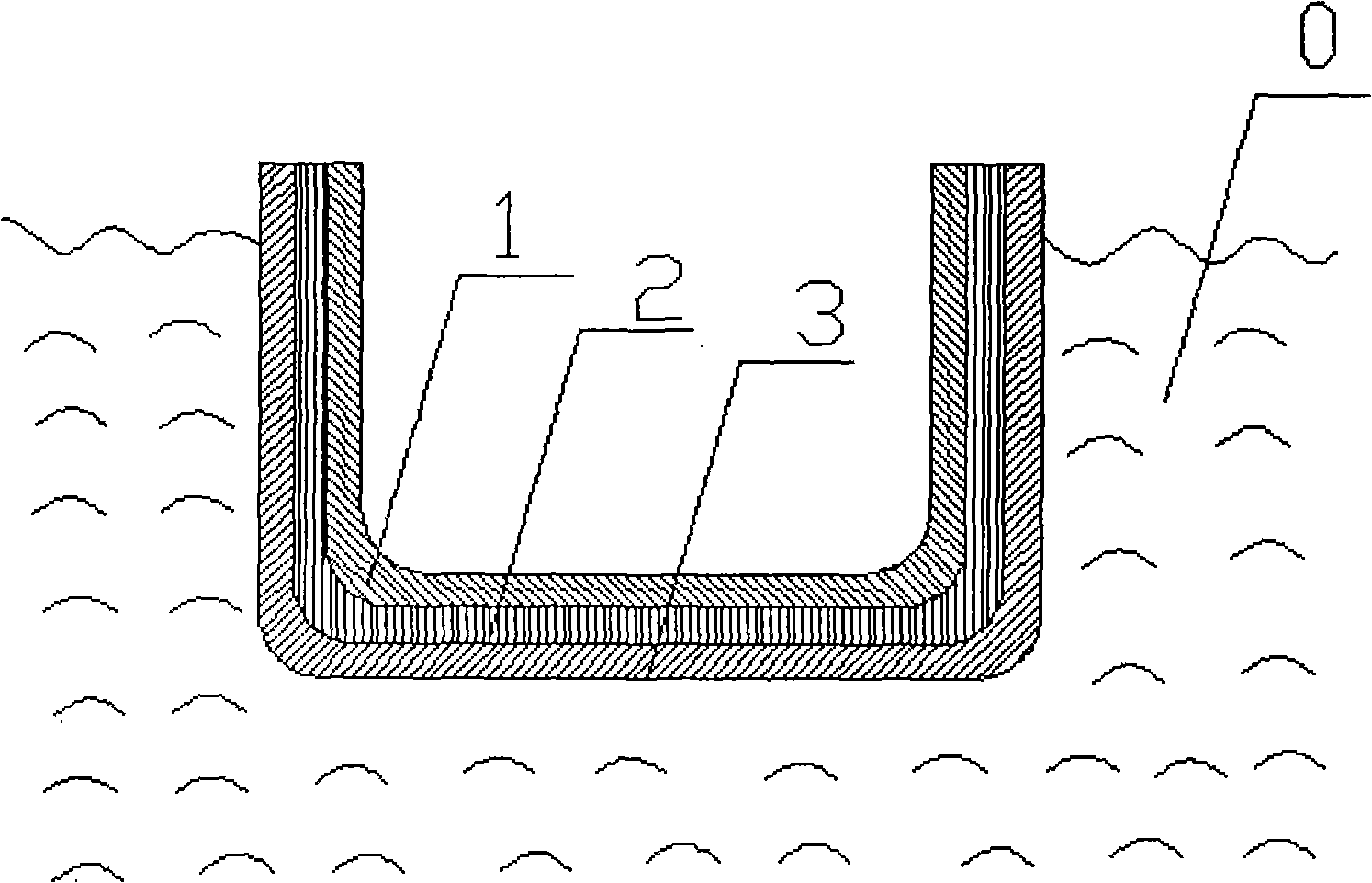

[0012] The bottom of the ship is made of 2 mm aluminum oxide ceramic patch, which is pasted on the metal base material 1 of the ship with epoxy resin, and the ceramic patch 3 and the ceramic patch 3 are seamlessly connected with epoxy resin 2, so that both Prevent seawater from permeating the ship's metal base material and prevent marine organisms from adhering.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a watercraft anticorrosion and antifouling method. Firstly, the material of the watercraft is processed with buffing treatment so as to enable the material to be capable of combining with ceramic wafers; then the ceramic wafers are tightly combined with the material of the watercraft through epoxy resin, electric welding, plating or adhesive. The ceramic wafers are adhibited at the underside of the watercraft and the part of the watercraft underwater or above waterline, including the area of the bulbous bow, the area of the screw-shaft tube of the propeller, the area of the rudder, the area of the ballast tank and the double-deck underfloor. The ceramic wafers are interconnected through epoxy resin, electric welding, plating or adhesive, or are interconnected mechanically, forming a watercraft shell. The invention has the good effects that the ceramic wafers are arranged at the exterior of the watercraft to withstand corrosion from seawater and halobios to the watercraft and makes use of the intensity of the substrate material of the watercraft and the characteristics of corrosion resistance and fouling resistance. The invention causes no pollution to marine environment and is effective in a long time and can reduce the resistance to the watercraft during sailing and increase the economical efficiency of the operation of the watercraft.

Description

technical field [0001] The invention relates to an anti-corrosion and anti-fouling method for a ship. The ceramic patch is closely combined with the ship hull material as the ship shell, and is especially suitable for effectively preventing corrosion of ships submerged in sea water and adhesion of marine organisms for a long time. Background technique [0002] Hull material is one of the important aspects to ensure the excellent performance, safety and reliability of the hull structure, and it is extremely vulnerable to corrosion, mainly including chemical corrosion, electrochemical corrosion and biological corrosion. The ship is in the marine environment, and its underwater part is not only subjected to strong electrochemical corrosion of seawater, but also fouled by marine organisms. Many marine organisms and microorganisms can adsorb on the surface of the hull or other metal structures, and grow and multiply. Especially in warm sea areas and in spring and summer, harmful...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B63B59/04

Inventor 沈岩单英春徐久军张银东

Owner DALIAN MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com