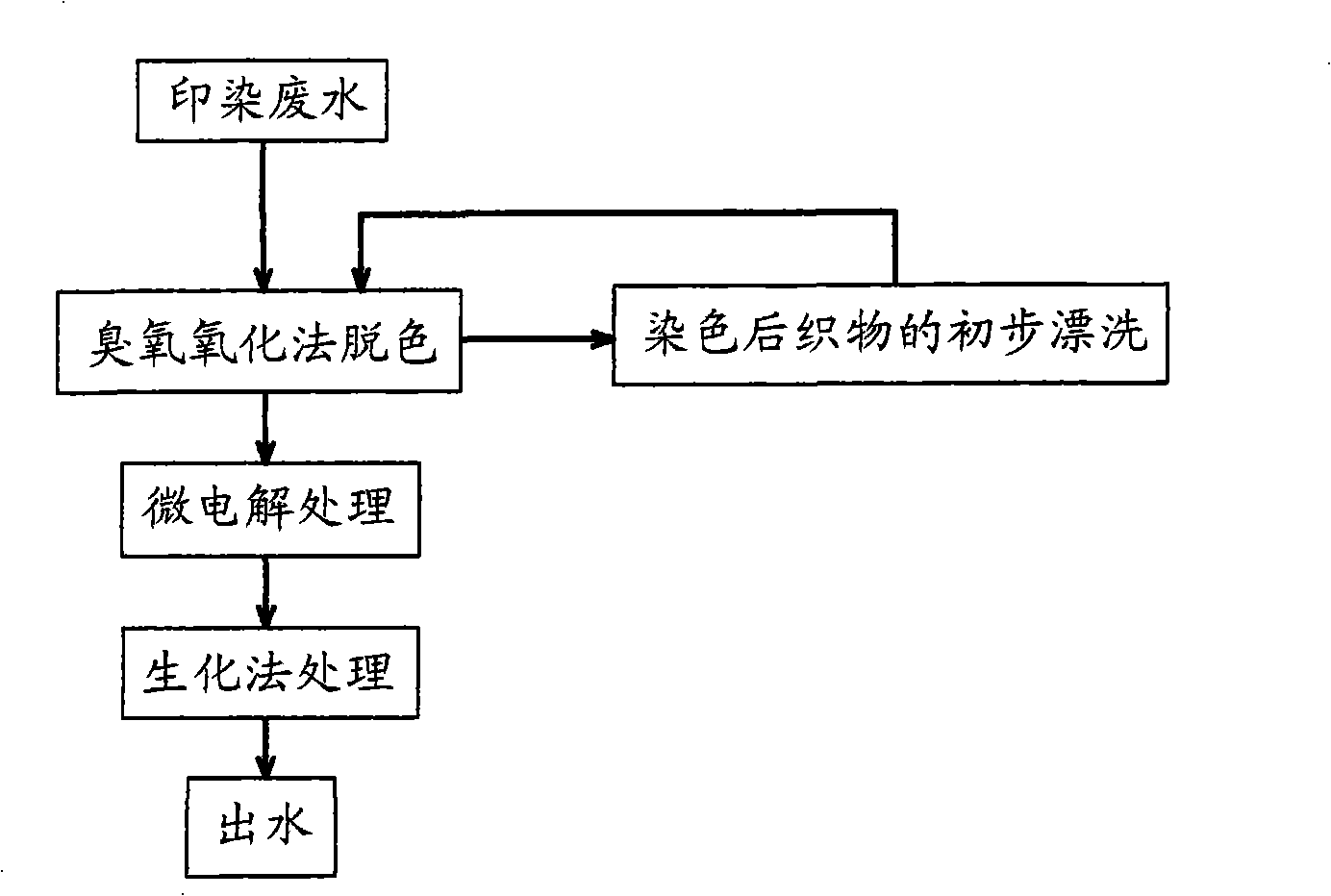

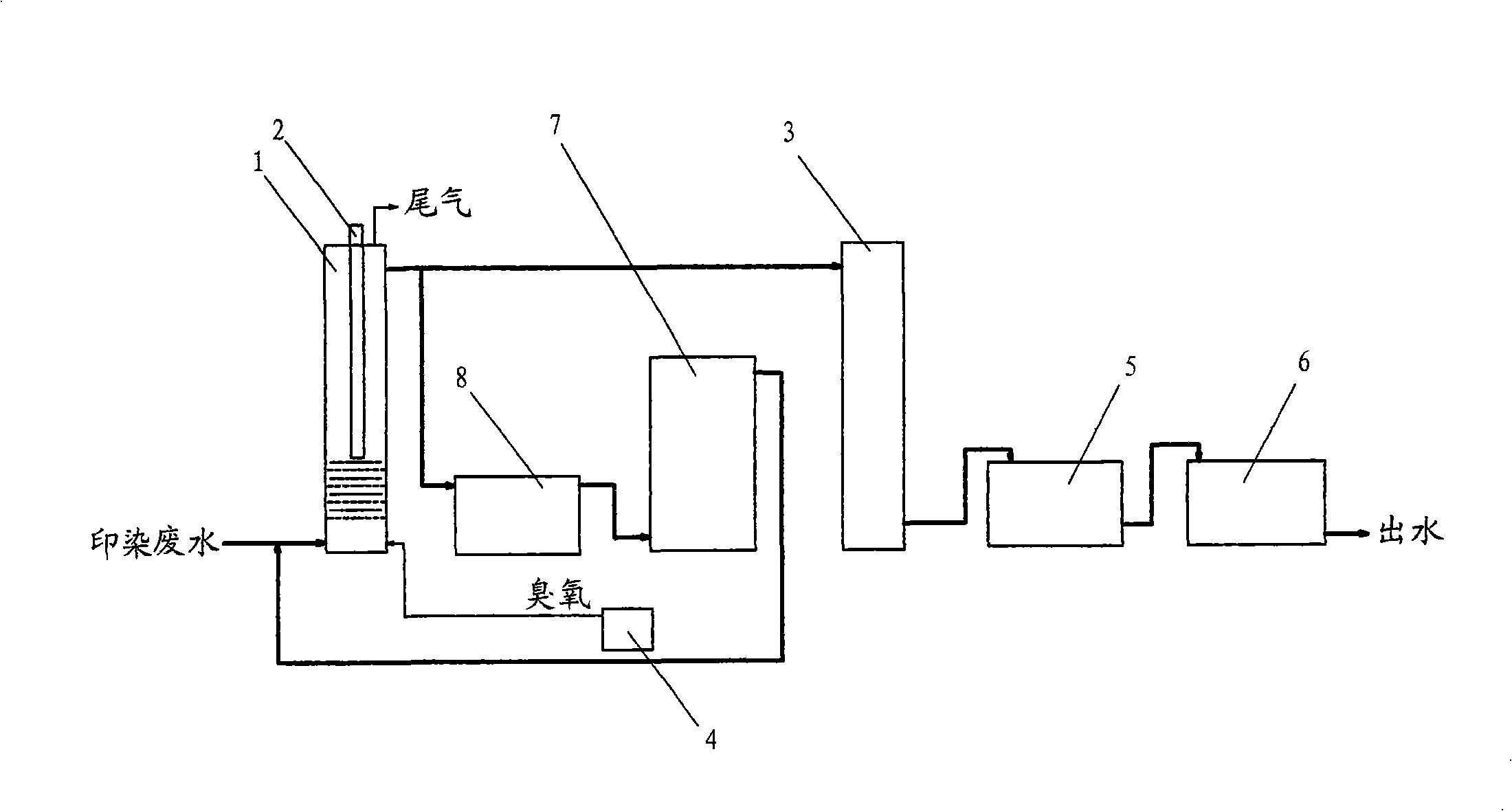

Multi-stage combined degradation and recycle method for printing and dyeing wastewater

A technology for printing and dyeing wastewater and its usage is applied in the field of degradation and reuse of printing and dyeing wastewater, which can solve the problems of high process requirements, high cost, and many technical influencing factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] ① COD of printing and dyeing wastewater before treatment Cr =850, chroma 180.

[0027] ② Adjust the pH value of the wastewater to approximately equal to 9, pour 50L of wastewater into the ozone-UV-activated carbon oxidation tower (adding 2000g of activated carbon), irradiate with a 50W ultraviolet lamp, and blow ozone from the bottom of the oxidation tower for 0.2 hours , stop blowing ozone. The chromaticity is reduced to 10, and the amount of ozone depletion is about 0.7mg. The calculated ozone depletion per cubic waste water is about 0.14kg.

[0028] ③ Leave the waste water obtained in the previous step for 1 hour to decompose the excess ozone, and then pour it into the rinse tank. After the dyed fabric is initially rinsed, the chromaticity of the waste water rises to 160, COD Cr up to 1300. The sewage is decolorized through an ozone-UV-activated carbon oxidation tower, and the chromaticity is reduced to 15.

[0029] ④ Treat the waste water obtained in the previou...

Embodiment 2

[0034] ① COD of printing and dyeing wastewater before treatment Cr =1300, chroma 220.

[0035] 2. Adjust the pH value of the wastewater to approximately equal to 7, inject 50L of wastewater into the ozone-UV-activated carbon oxidation tower (wherein 2000g of activated carbon is added), blow into ozone from the bottom of the oxidation tower, and stop blowing into the ozone after 0.25 hours. The chromaticity is reduced to 20, and the amount of ozone depletion is about 1.05 mg. The calculated ozone depletion per cubic waste water is about 0.21 kg.

[0036] ③Put the wastewater obtained in the previous step into the rinsing tank, and perform preliminary rinsing on the dyed fabric. After reuse once, the chromaticity of the wastewater rises to 210, COD Cr up to 1950. After being decolorized by the ozone-UV-activated carbon oxidation tower, the chroma is reduced to 28, and then put into the rinsing tank for preliminary rinsing of the dyed fabric, and the chroma of the wastewater ris...

Embodiment 3

[0042] ① COD of printing and dyeing wastewater before treatment Cr =710, chroma 350.

[0043] ②Adjust the pH value of the wastewater to approximately equal to 9, put 50L of wastewater into the ozone-UV-activated carbon oxidation tower, blow in ozone from the bottom of the oxidation tower, and stop blowing in ozone after 0.25 hours. The chromaticity is reduced to 12, and the amount of ozone depletion is about 0.85 mg. The calculated ozone depletion per cubic waste water is about 0.17 kg.

[0044] ③Put the wastewater obtained in the previous step into the rinsing tank, and perform preliminary rinsing on the dyed fabric. After reuse once, the chromaticity of the wastewater rises to 380, COD Cr up to 1250. After being decolorized by the ozone-UV-activated carbon oxidation tower, the chroma is reduced to 18, and then poured into the rinse tank for preliminary rinsing of the dyed fabric, and the chroma of the wastewater rises to 385 after being reused twice, COD Cr up to 1640. R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com