Depth detection method for steel surface hardening layer

A hardened layer depth and detection method technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of material surface damage, difficulty in obtaining exact data of the surface hardened layer depth profile, non-destructive testing requirements, etc., to achieve good results consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

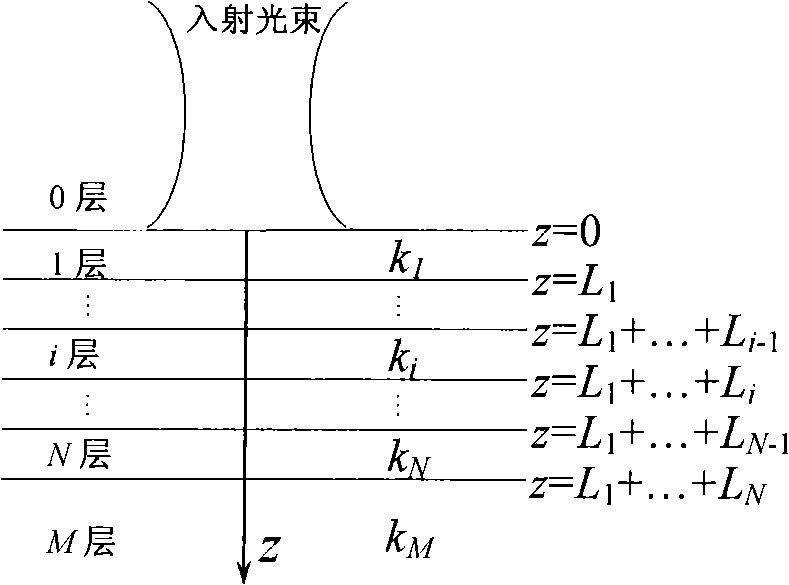

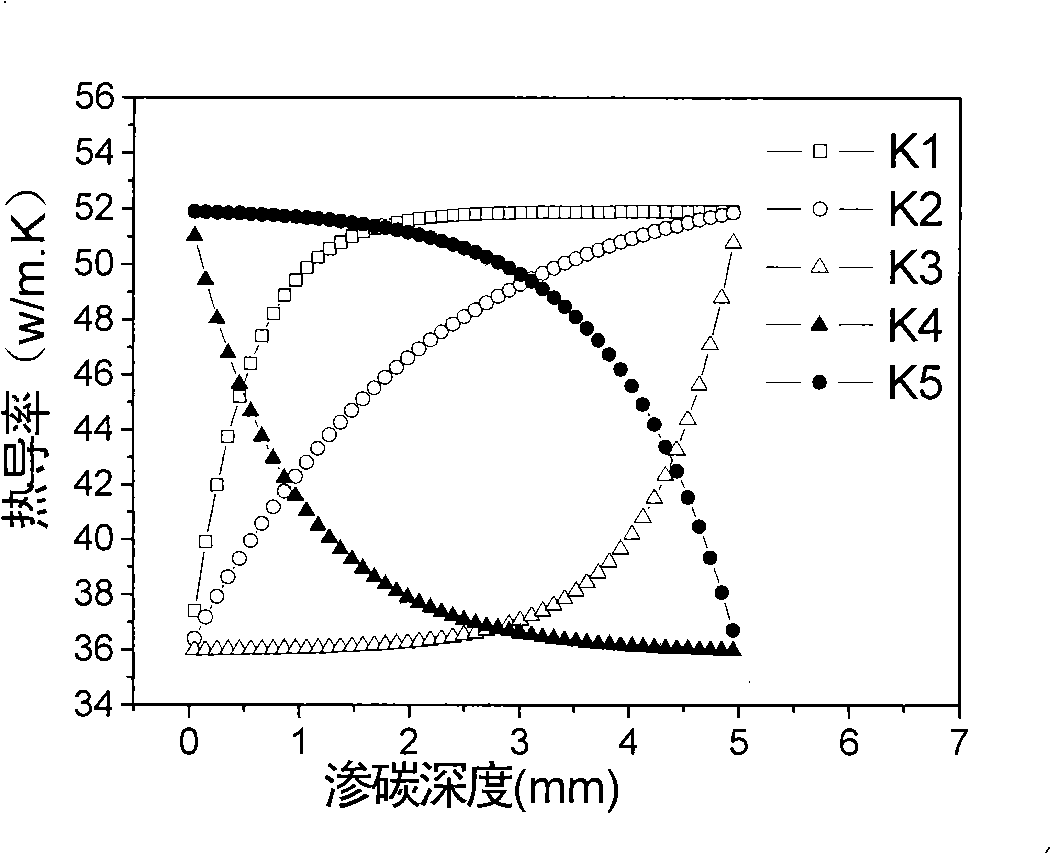

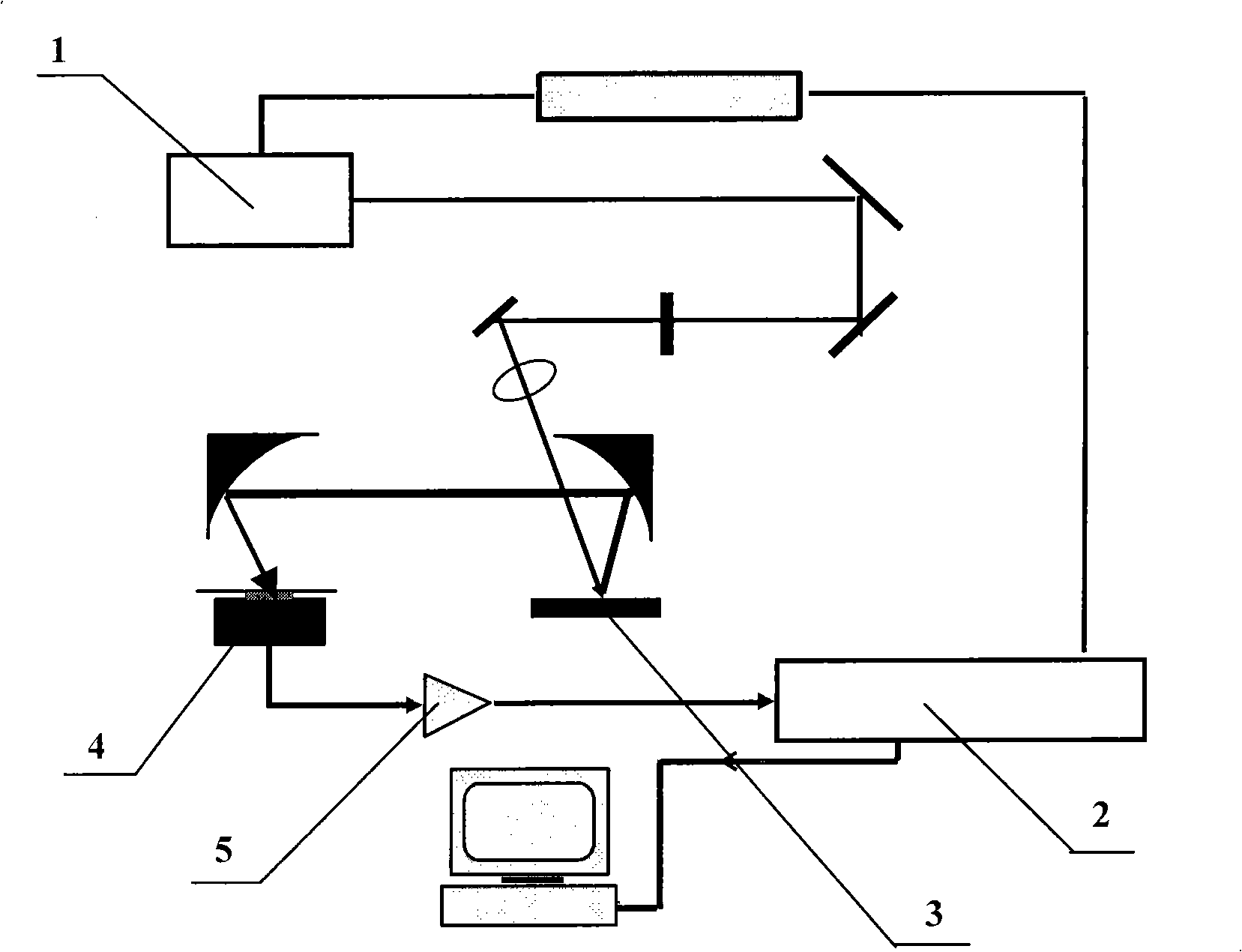

[0025] A hardened steel sample can be considered as an inhomogeneous system consisting of an inhomogeneous layer (hardened layer) and a base layer (unhardened core layer). The physical property parameters of the inhomogeneous layer, such as microhardness, thermal conductivity, and thermal diffusivity, are all functions of depth and have different distributions along the depth direction. In order to quantitatively measure the inhomogeneity system, a multi-layer thermal wave propagation model is proposed and used to simplify the complex inhomogeneity. See attached figure 1 As shown, the inhomogeneous layer is divided into N layers, and each layer can be considered as uniform. When the number of layers is selected properly (for example, the number of layers is large enough), the multi-layer model is very close to the continuous model. from figure 1 It can be seen from the figure that the whole system includes N+2 layers, the 0 layer and the M layer are the air and the base lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com