Underwater dry type soldering camera

A technology for cameras and color cameras, which is applied to cameras, image communications, camera bodies, etc., can solve problems such as products that have not yet been found, and achieve the effects of low cost, easy use, maintenance and repair, and convenience for underwater work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

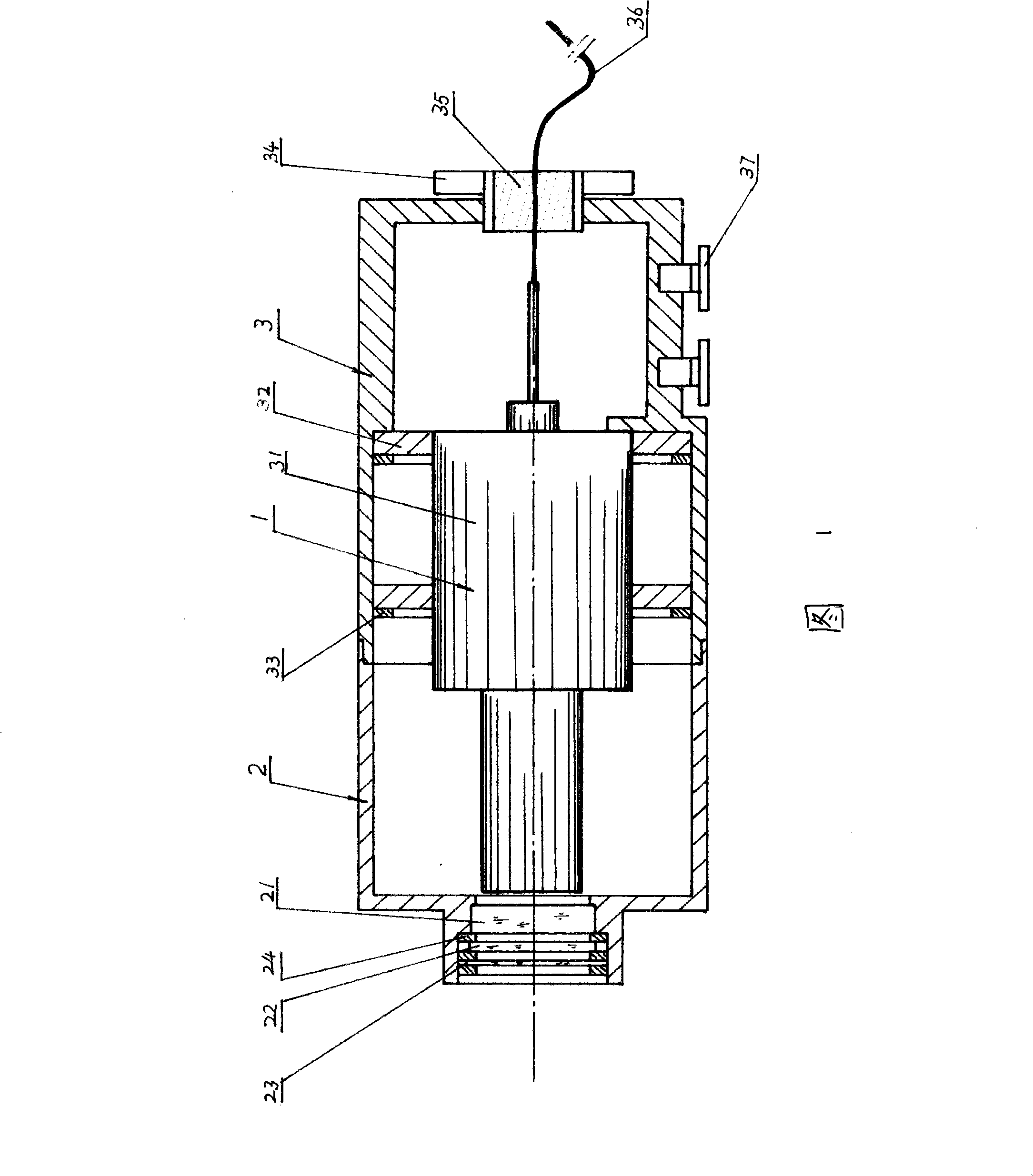

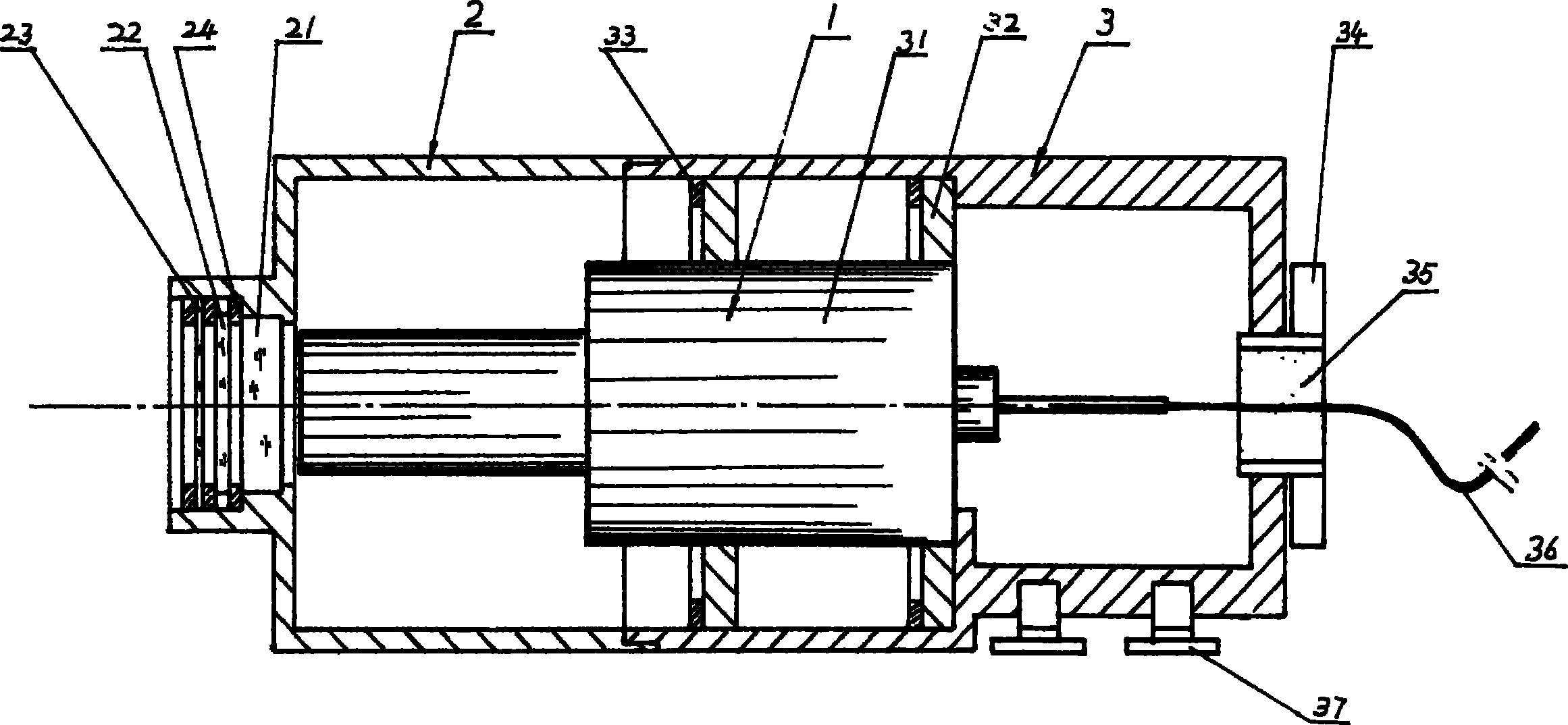

[0011] As shown in Figure 1, an underwater dry welding camera is mainly composed of a camera 1, a lens protection tube 2 and a camera protection tube 3, wherein: the lens protection tube 2 is a cylindrical structure with a double diameter, and its front ends are installed in sequence Optical filter 21, attenuation sheet 22 and protective mirror 23 are fixed with lens collar 24 respectively; Two snap rings 32 are fixed in the camera protective tube with collar 33, and color camera 31 passes through the interference with snap ring 32 Fitted and fixed in the camera protection tube 3, the bottom of the camera protection tube 3 is equipped with a sealing bolt 34, in which a moisture-proof sealing ring 35 is embedded, and the power supply and video line 36 of the color camera 31 are drawn out of the camera protection tube 3 through the moisture-proof sealing ring 35 , the other side of the bottom is provided with a fixing bolt 37, and the lens protection tube 2 and the camera protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com