Motor

A wire and winding technology, applied to the shape/style/structure of winding conductors, can solve problems such as cumbersome process, increased cost, and prolonged production cycle, and achieve the effects of simple process structure, increased output voltage, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] One of the embodiments: a single-phase AC motor.

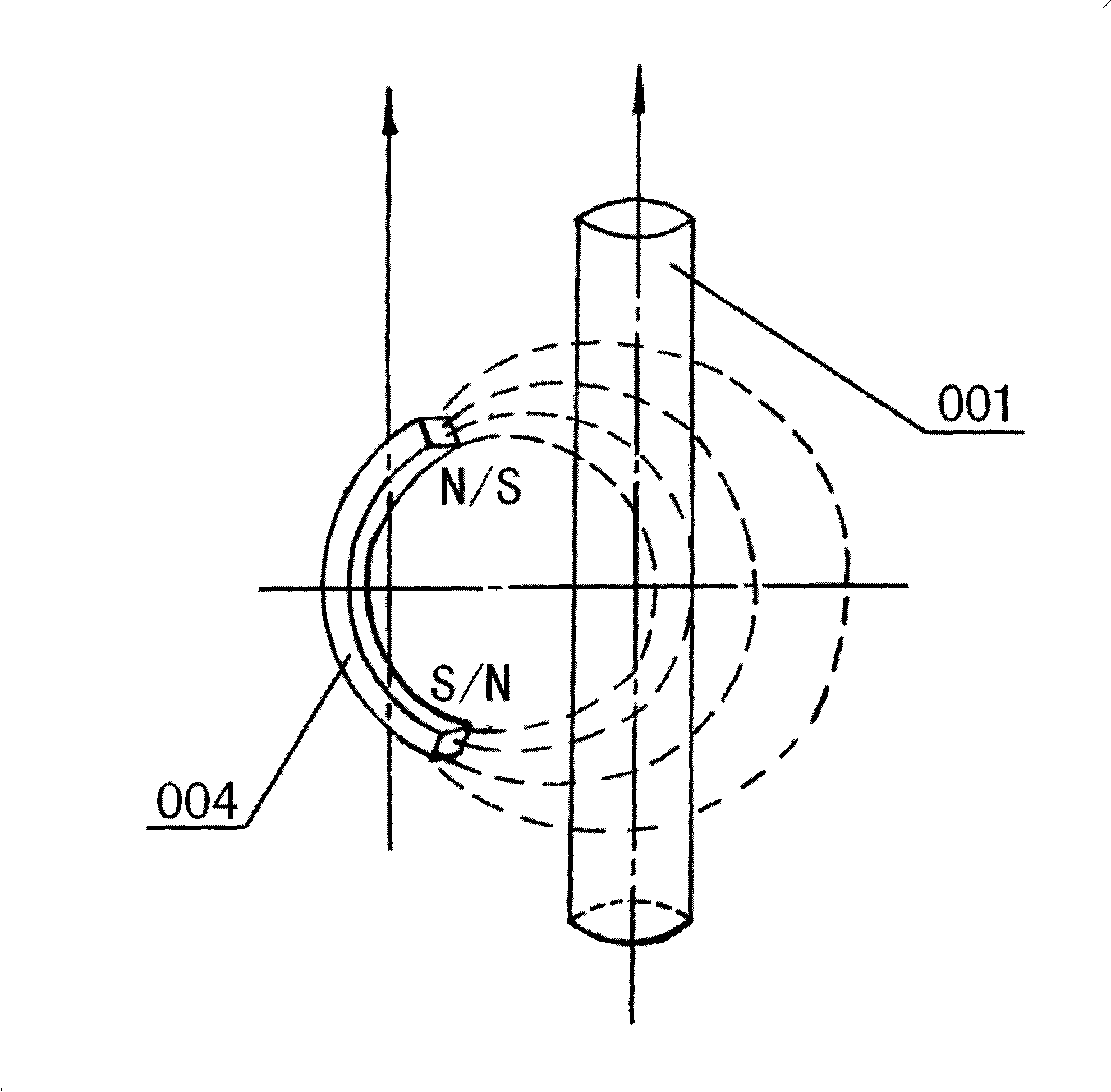

[0042] The simplest utility type such as Figure 6 shown. Figure 6 Among them, there are two C-type iron stator cores 101-1 and 101-2 on the upper and lower sides of the shaft 103, and at the counterparts of the two stator cores 101-1 and 101-2, there are two fixed The rotors 102-1 and 102-2 on the shaft have their own magnetic fields, which is called dual magnetic source type. There is a core iron 105 between the two rotors, which communicates with the magnetic circuit, and it is two ring magnet magnetic circuits corresponding to opposite directions, such as Figure 7 In the upper middle part, the magnetic poles of the two magnetic sources are opposite. It has two separate stator windings 104-1 and 104-2. Figure 7 yes Figure 6 side view.

[0043] The second embodiment is a three-phase alternating current motor, and it is still described with the generator earlier.

[0044] Figure 8 , Figure 9 A three-phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com