Medicament composition for treating respiratory disease

A technology for respiratory diseases and compositions, which is applied in the field of pharmaceutical compositions for asthma, and can solve problems such as inconvenient use, slow onset of effect, and large dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

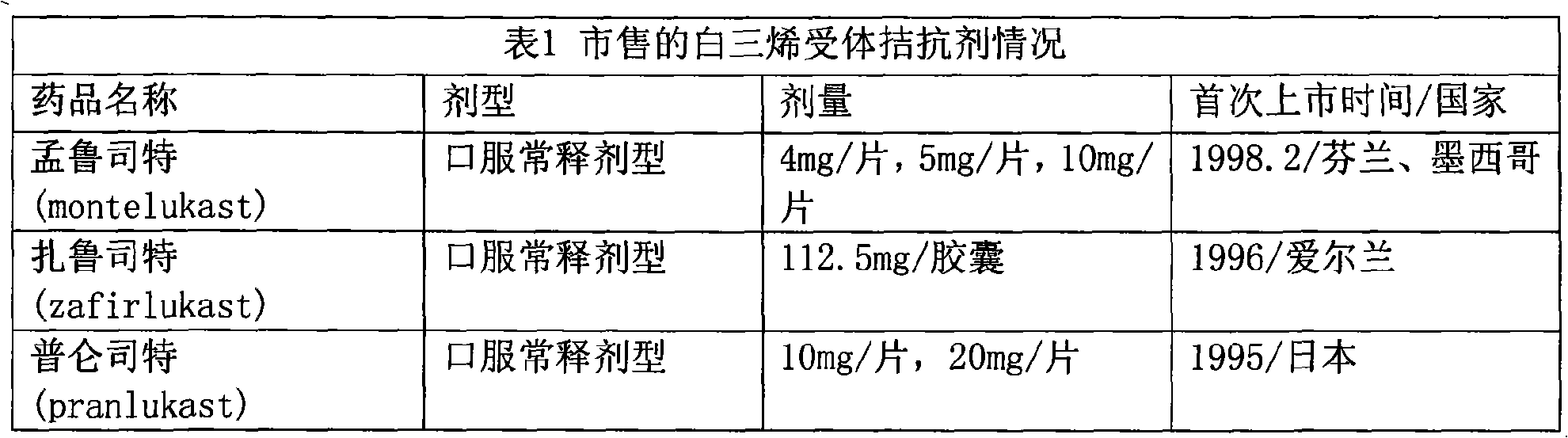

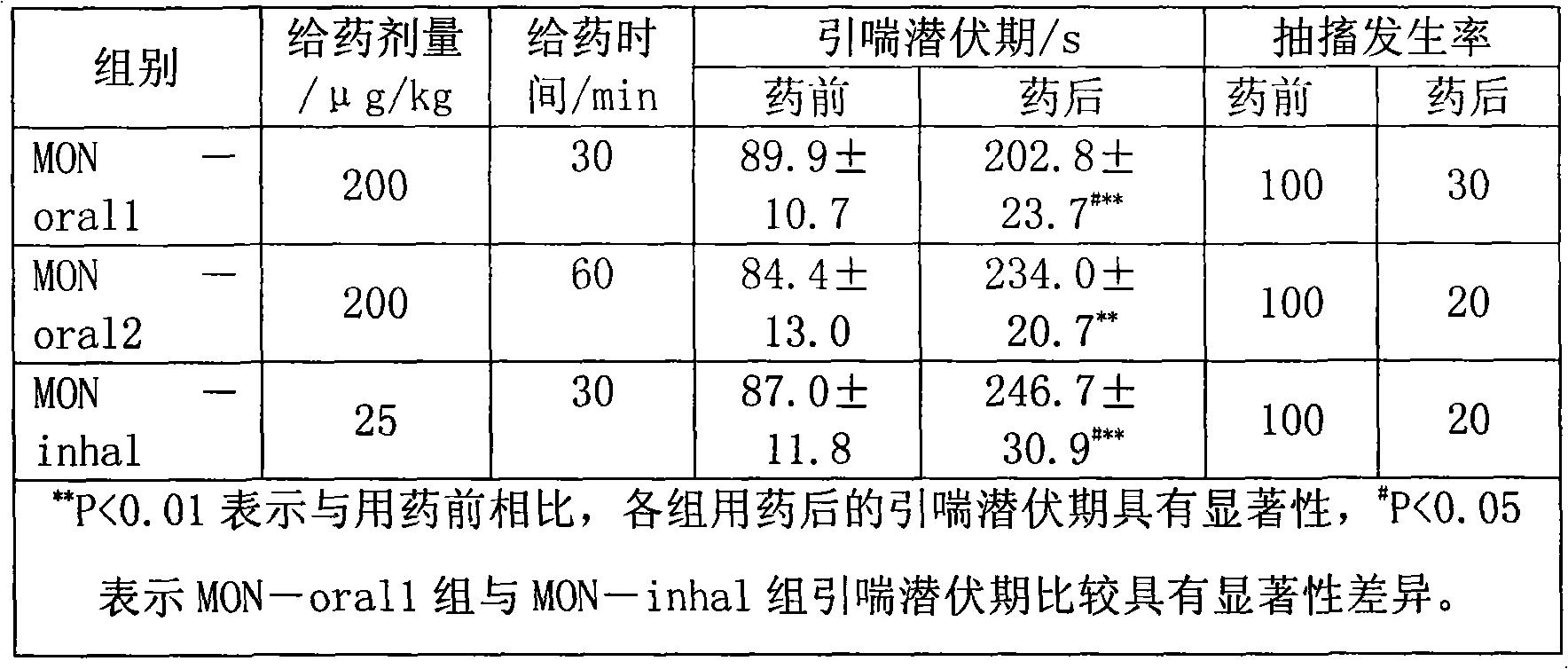

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Montelukast 20g

[0030] Ethanol 750g

[0031] Propylene glycol 150g

[0032] Dichlorodifluoromethane 1500g

[0033] Preparation process: add the prescribed amount of montelukast into ethanol and propylene glycol, stir, heat in a warm water bath to dissolve the raw materials, filter with a sand core funnel, fill in divided doses, seal the dose valve system, and add Inject dichlorodifluoromethane under pressure to obtain the product, theoretically fill 1000 bottles, and the filling yield is above 85%. After 30 minutes of leak detection in a water bath at 45-50°C, there is no leakage. Each bottle is 50 presses, and each press contains 400 μg of montelukast.

Embodiment 2

[0035] Montelukast Sodium 12.5g

[0036] Ethanol 200g

[0037] Glycerol 19.5g

[0038] HFA227 750g

[0039] HFA134a 750g

[0040] Vitamin C 7.5g

[0041] Preparation process: Add the prescribed amount of montelukast into vitamin C, ethanol and glycerol that are evenly stirred, stir, heat in a warm water bath to dissolve the raw materials, filter with a sand core funnel, fill in divided doses, and seal the dose The valve system is further pressurized HFA134a and HFA227 respectively, namely, 1000 bottles can be theoretically filled, and the filling yield is above 85%. After 30 minutes of leak detection in a water bath at 45-50°C, there is no leakage. 50 presses per bottle, each press contains 250 μg of montelukast sodium

Embodiment 3

[0043] Montelukast 5g

[0044] Ethanol 750g

[0045] Glycerin 150g

[0046] Dichlorotetrafluoroethane 1500g

[0047] Sodium metabisulfite 7.5g

[0048] Preparation process: Add the prescribed amount of montelukast into the well-stirred sodium metabisulfite, ethanol and glycerin, stir, heat in a warm water bath to dissolve the raw materials, filter with a sand core funnel, fill in divided doses, and seal the dose valve system , and pressurize the dichlorotetrafluoroethane respectively to obtain the product, which can be theoretically packed into 1000 bottles, and the filling yield is above 85%. After 30 minutes of leak detection in a water bath at 45-50°C, there is no leakage. Each bottle contains 50 presses, and each press contains 100 μg of montelukast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com