Transfer printing method for transferring print film containing ultraviolet curing type adhesive

A technology for transferring printing films and adhesives, which is used in the production of special varieties of printed matter, such as printing, transfer printing, rotary printing machines, etc. and other problems, to achieve the effect of firmer combination, adaptability to large-scale industrial production, and fast transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 (taking non-absorbent hard substrate transfer printing as an example)

[0025] 1. Preparation of printing film

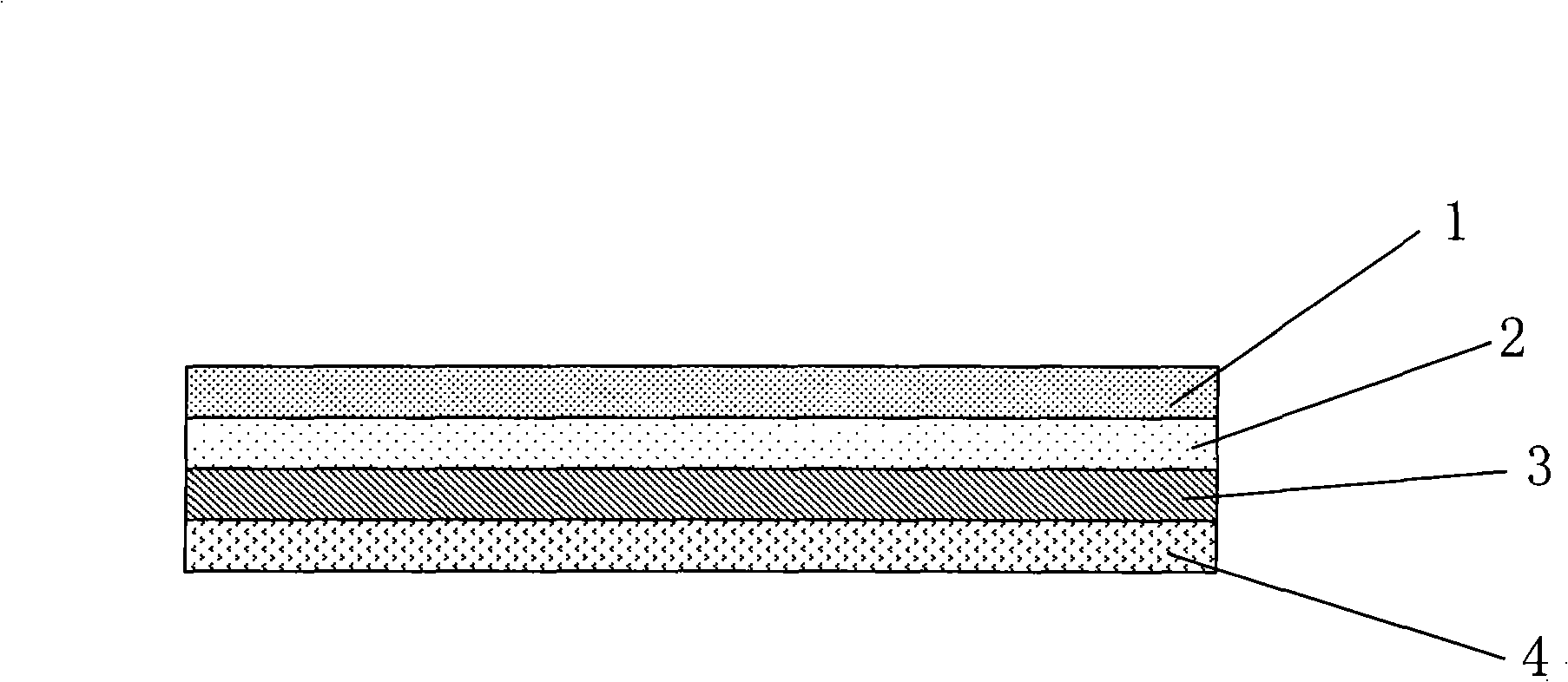

[0026] figure 1 It is the first printing film of the present invention. The top layer of the printing film is a base film 1 , the second layer is an acrylic resin layer 2 , the third layer is a printing ink layer 3 , and the fourth layer is an adhesive layer 4 . The production process is as follows: use a gravure printing machine or a coating machine to print an acrylic resin layer on the surface of a base film as a protective layer, use ink to print pre-designed decorative graphics on the acrylic resin layer, and print on the graphic layer The gravure printing machine is used to directly print the adhesive on the surface or apply the adhesive on the coating machine, and the finished product is rewound, cut and packaged.

[0027] Adhesives are formulated as follows:

[0028] Epoxy acrylate resin 34%

[0029]Polyester acrylate resin 14.4%

[...

Embodiment 2

[0042] Embodiment 2 (taking the transfer printing of absorbent soft substrate as an example)

[0043] 1. Preparation of printing film

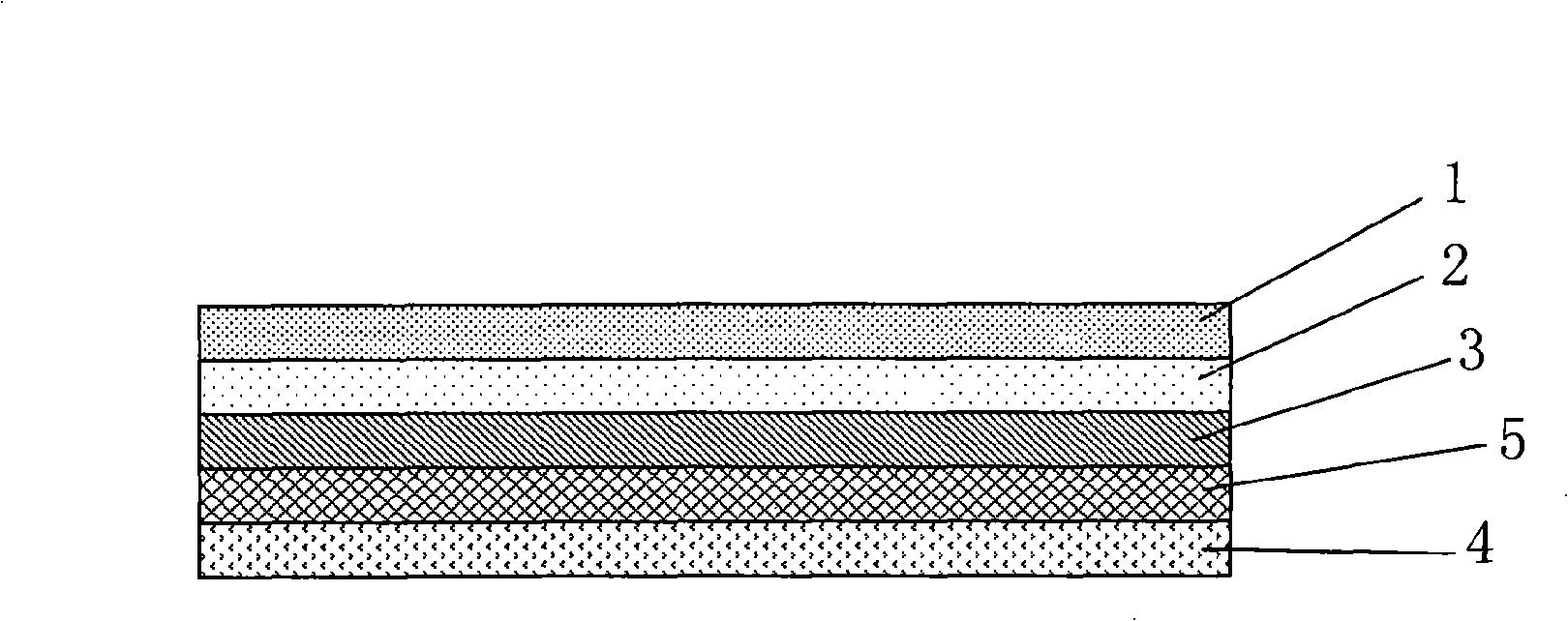

[0044] image 3 It is the second printing film of the present invention. The top layer of the printing film is a base film 1, the second layer is an acrylic resin layer 2, the third layer is a printing ink layer 3, the fourth layer is a vacuum aluminized layer 5, and the fifth layer It is the adhesive layer 4. The production process is as follows: use a gravure printing machine or a coating machine to print an acrylic resin layer on the surface of a base film as a protective layer, print pre-designed decorative graphics on the acrylic resin layer, and use vacuum aluminum plating. , plate a layer of metal aluminum on the decorative graphic layer, and then use a gravure printing machine to directly print an adhesive on the aluminum layer or apply an adhesive on a coating machine, then roll, cut, and package the finished product.

[0045] Adhe...

Embodiment 3

[0060] 1. Preparation of printing film (take the transfer printing of absorbent soft substrate as an example)

[0061] Figure 5 It is the third printing film of the present invention. The top layer of the printing film is a base film 1, the second layer is an acrylic resin layer 2, the third layer is a printing ink layer 3, the fourth layer is a vacuum aluminum layer 5, and the fifth layer is the adhesive layer 4 , and the sixth layer is the release layer 6 . The production process is as follows: use a gravure printing machine or a coating machine to print an acrylic resin layer on the surface of a base film as a protective layer, print pre-designed decorative graphics on the acrylic resin layer, and use vacuum aluminum plating. , plate a layer of metal aluminum on the decorative graphic layer, then use a gravure printing machine to directly print an adhesive on the aluminum layer or apply an adhesive on a coating machine, and finally apply an anti-adhesive layer for winding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com