Booster pressure-storing wind motor

A technology for wind turbines and boosters is applied in the directions of wind turbines, wind turbine assemblies, and wind turbine components to achieve the effects of reducing manufacturing costs, wide application range and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

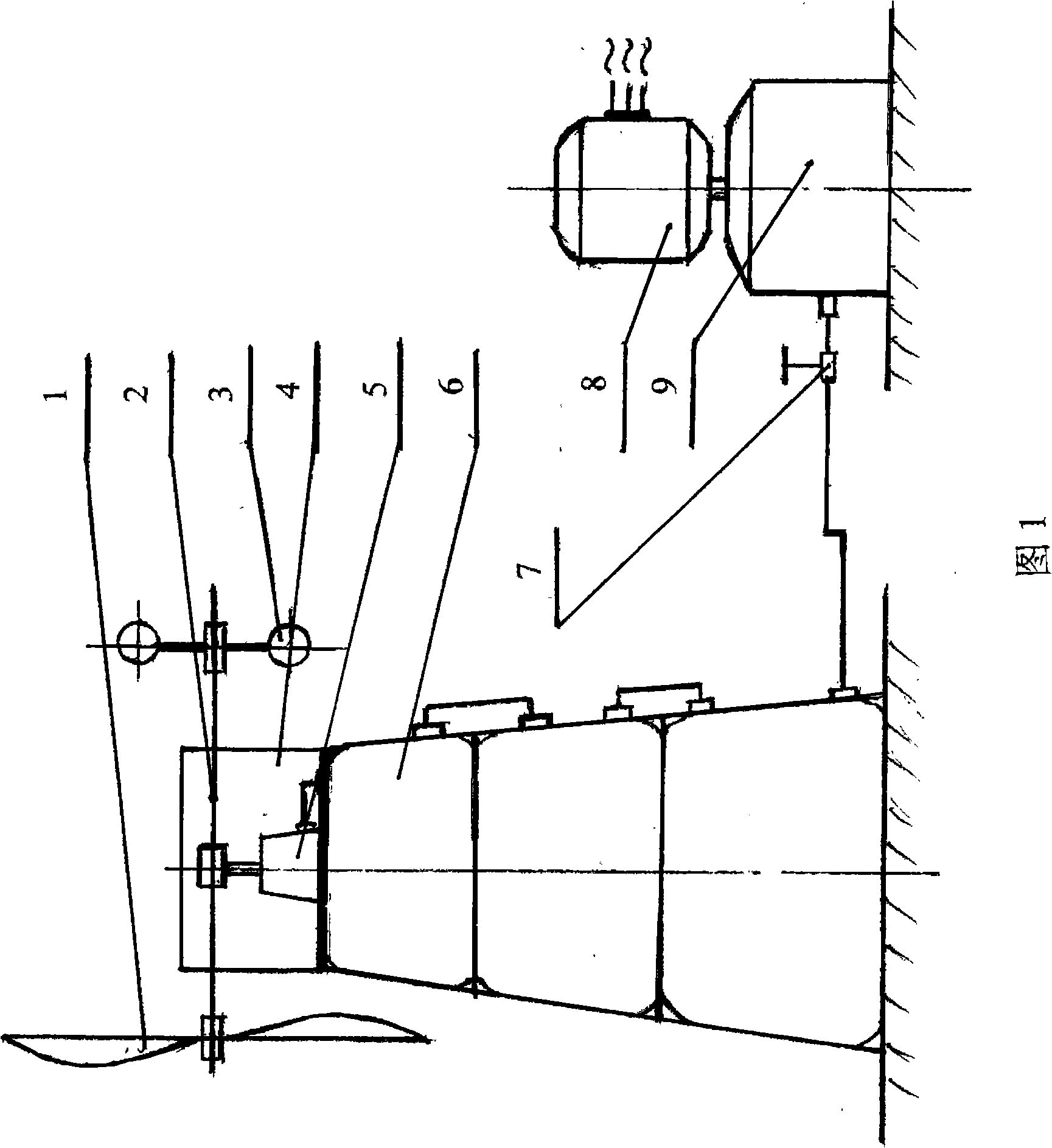

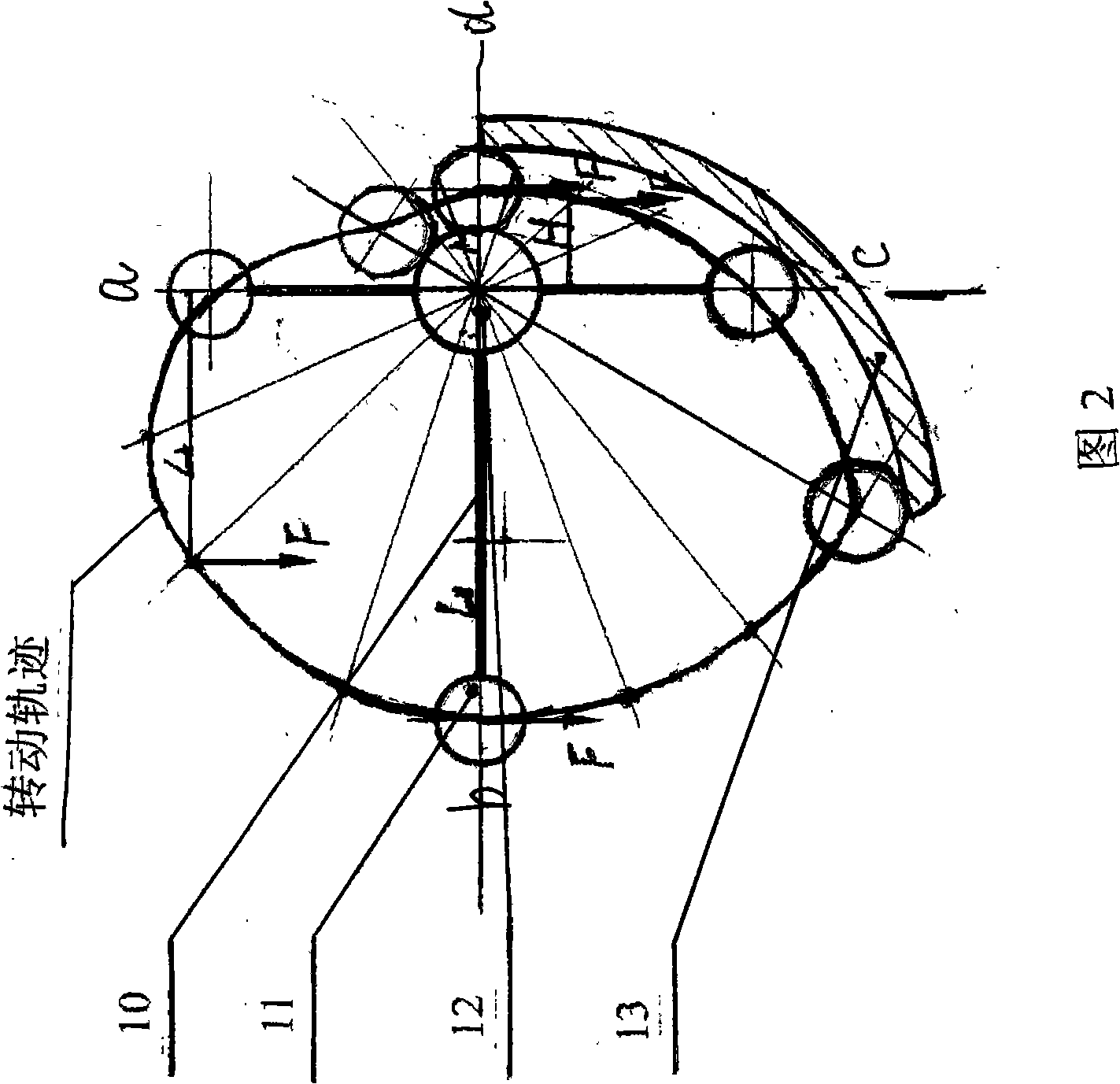

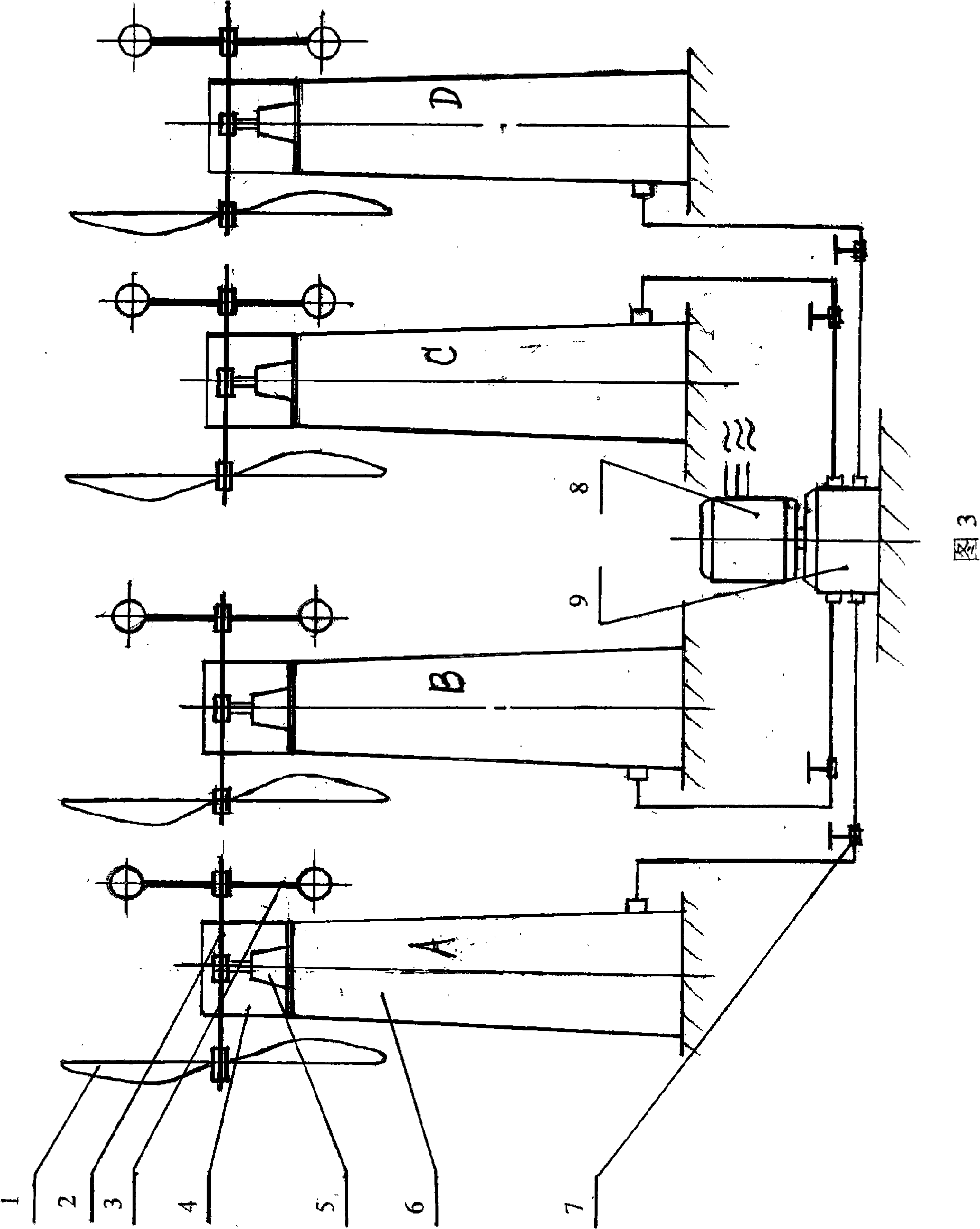

[0030]If the newly developed and designed booster pressure storage wind turbine is matched with a 3 MW variable power generator, in order to ensure the output power of wind power generation is 3 MW, four booster pressure storage wind turbines with a rotor diameter of 60 meters are used in parallel. use. The output power of each wind wheel is 650 kilowatts, plus the automatic booster, the output power of each wind turbine is 650 kilowatts×120%=780 kilowatts. Four wind turbines are connected in parallel, and the total output power can reach 780×4=3120 kilowatts. That is: 3.12 megawatts can fully meet the needs of 3 megawatts of variable power generators. With the help of the booster, the wind wheel can start to drive the main shaft to rotate if there is a wind speed of 1 m / s. Through the speed-up of the main shaft itself (the main shaft is designed and manufactured with a 12-fold speed-up device). Then drive the air pump to work, and the air pump is completed by two parts: ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com