Concrete delivery pump adjustable double-layer seal assembly

A concrete delivery pump, double-layer sealing technology, applied in the direction of engine seal, pump, pump components, etc., can solve the problems of poor wear resistance, dry friction, poor oil supply, etc., to improve operation reliability and prolong service life , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

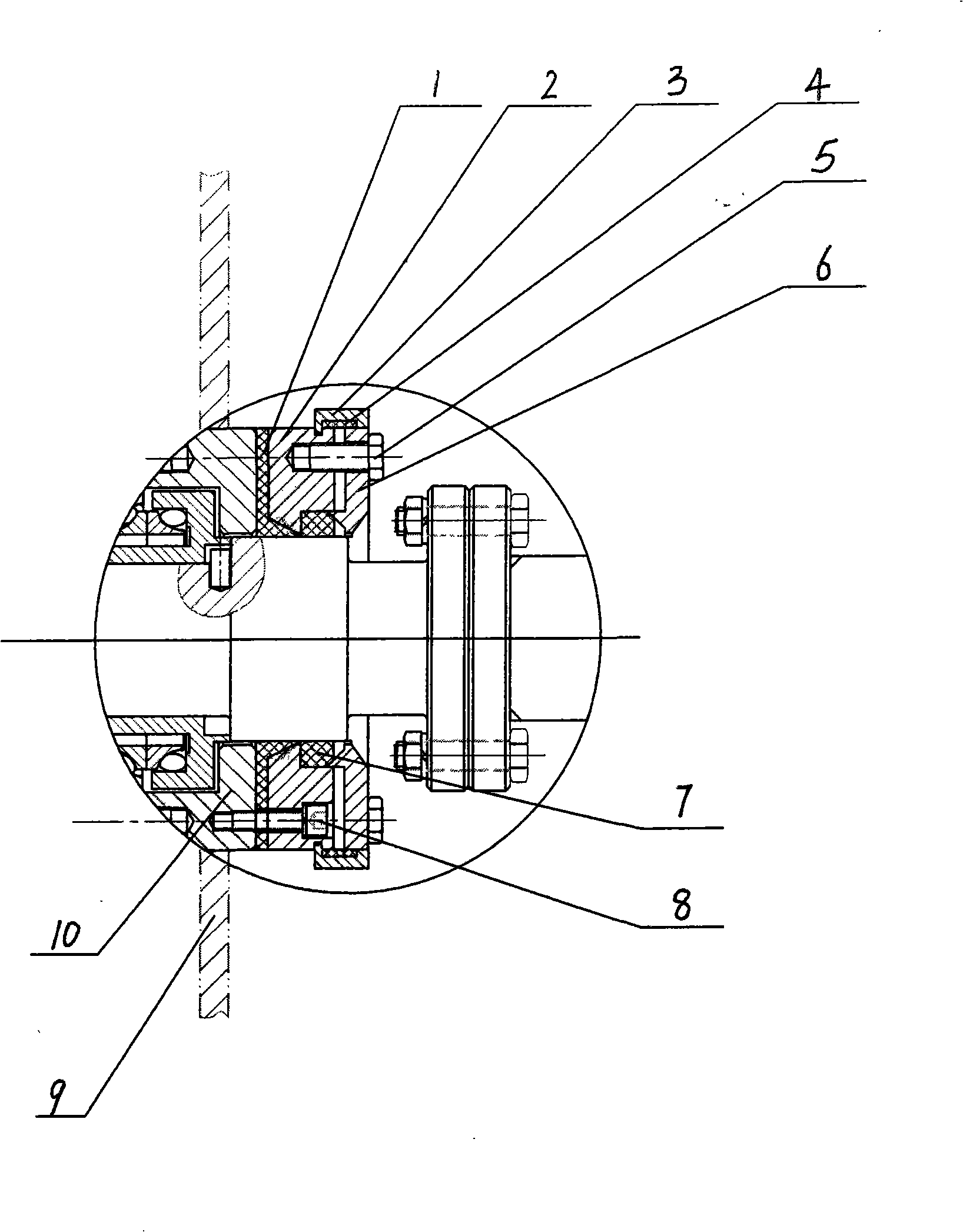

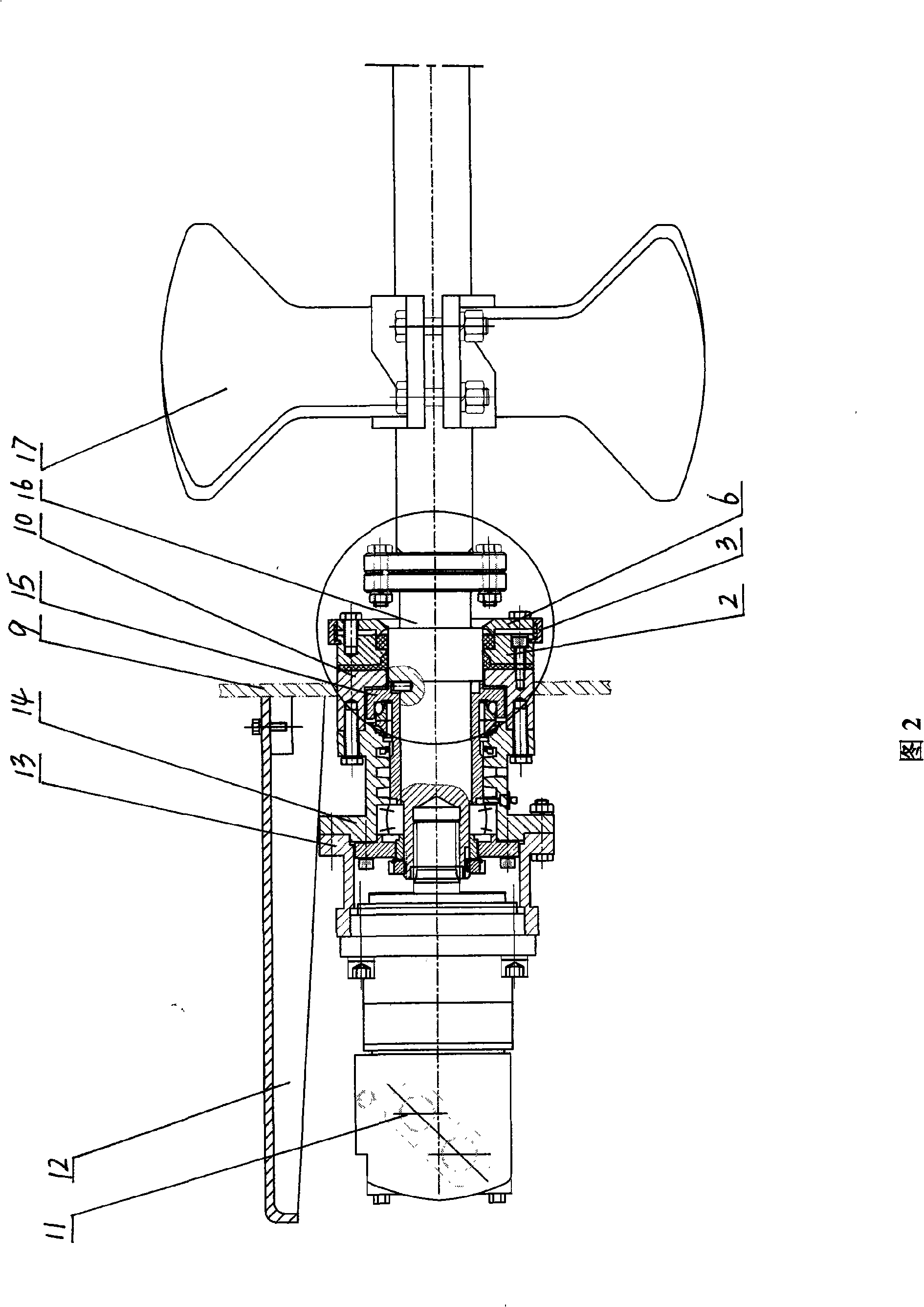

[0008] from figure 1 As can be seen from the structural schematic diagram of the adjustable double-layer sealing assembly of the concrete delivery pump of the present invention, the present invention consists of a sealing sleeve 1, a fixed sleeve 2, a sealing ring 7, an adjustable plate 6, an adjusting bolt 5, a gasket 4, a sealing The hoop is composed of 3 other parts. The fixed sleeve 2 is located around the stirring shaft 16 and is connected to the hopper stirring seat 10 by bolts 8 . There are double-layer sealing elements between the fixed sleeve 2 and the stirring shaft 16 : the sealing sleeve 1 and the sealing ring 7 . The sealing sleeve 1 is made of high-quality rubber material, and the sealing ring 7 is made of super wear-resistant sealing material, and super wear-resistant carbon fiber can be selected for use. There is an inclined surface on the inner surface of the fixed sleeve 2, and the outer side of the sealing sleeve 1 is in contact with the inclined surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com