Remote operation planar redundant manipulator automated guided intelligent element, system and method

A technology of intelligent units and robotic arms, applied in the directions of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high computing power and integration ability of various sensory information, complex system structure, simple algorithm, etc., to improve the operation Effectiveness of efficiency and operational performance, simplified system wiring, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

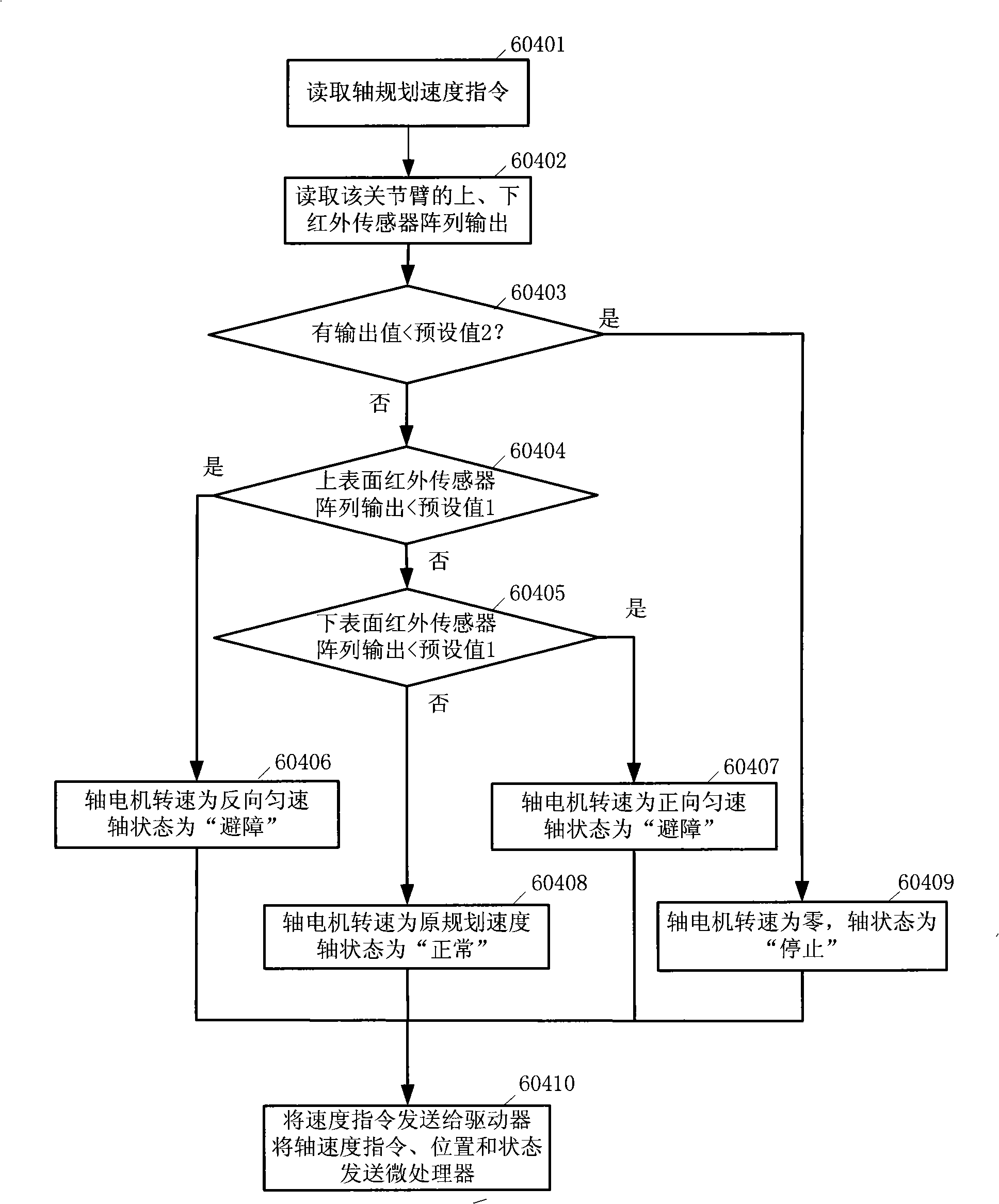

[0076] This embodiment describes the present invention in detail with regard to the autonomous obstacle avoidance method and the intelligent unit of the teleoperated planar four-degree-of-freedom robotic arm.

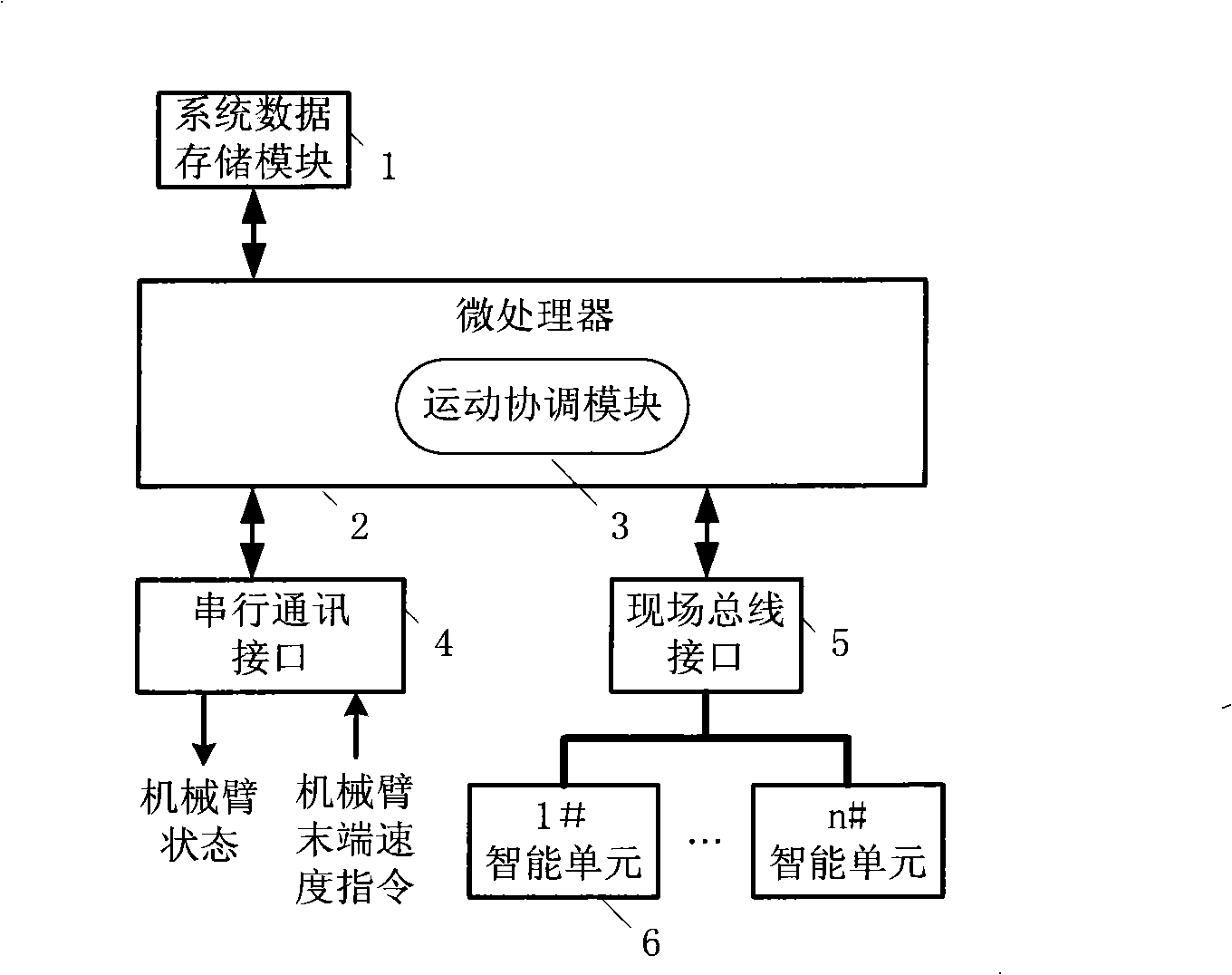

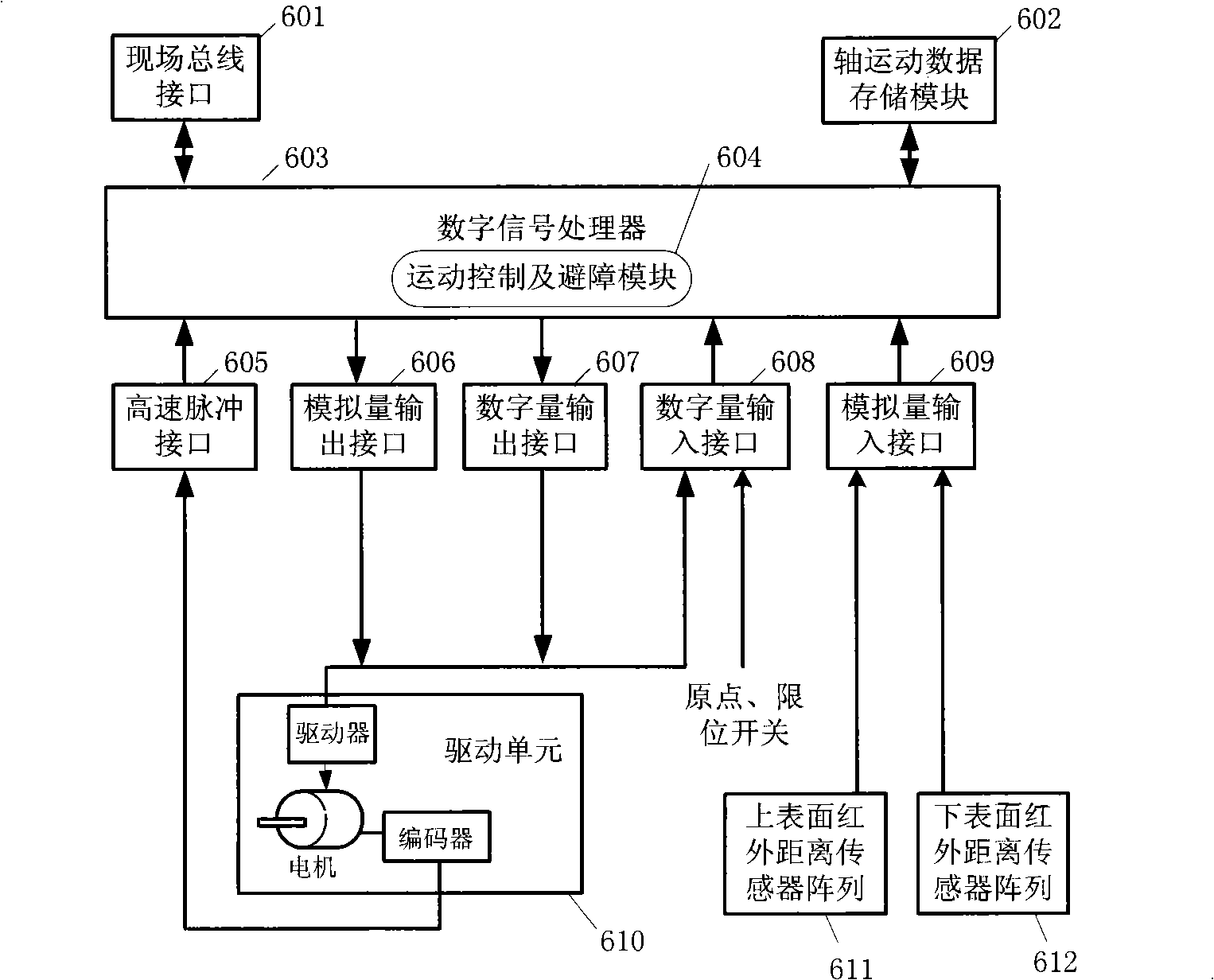

[0077] Such as figure 1 As shown, the teleoperation planar redundancy manipulator motion control and obstacle avoidance system described in this embodiment includes a system data storage module 1, a microprocessor 2, a motion coordination module 3, a serial communication interface 4, and a field bus interface 5 And 1-4# intelligent unit 6. Among them, the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com