Liquid ethylene based polysilazane resin and preparation thereof

A technology of vinyl polysilazane and methyl vinyl dichlorosilane, which is applied in the field of liquid vinyl polysilazane resin and its preparation, and can solve the problem that the viscosity is difficult to meet the requirements of ceramic precursors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

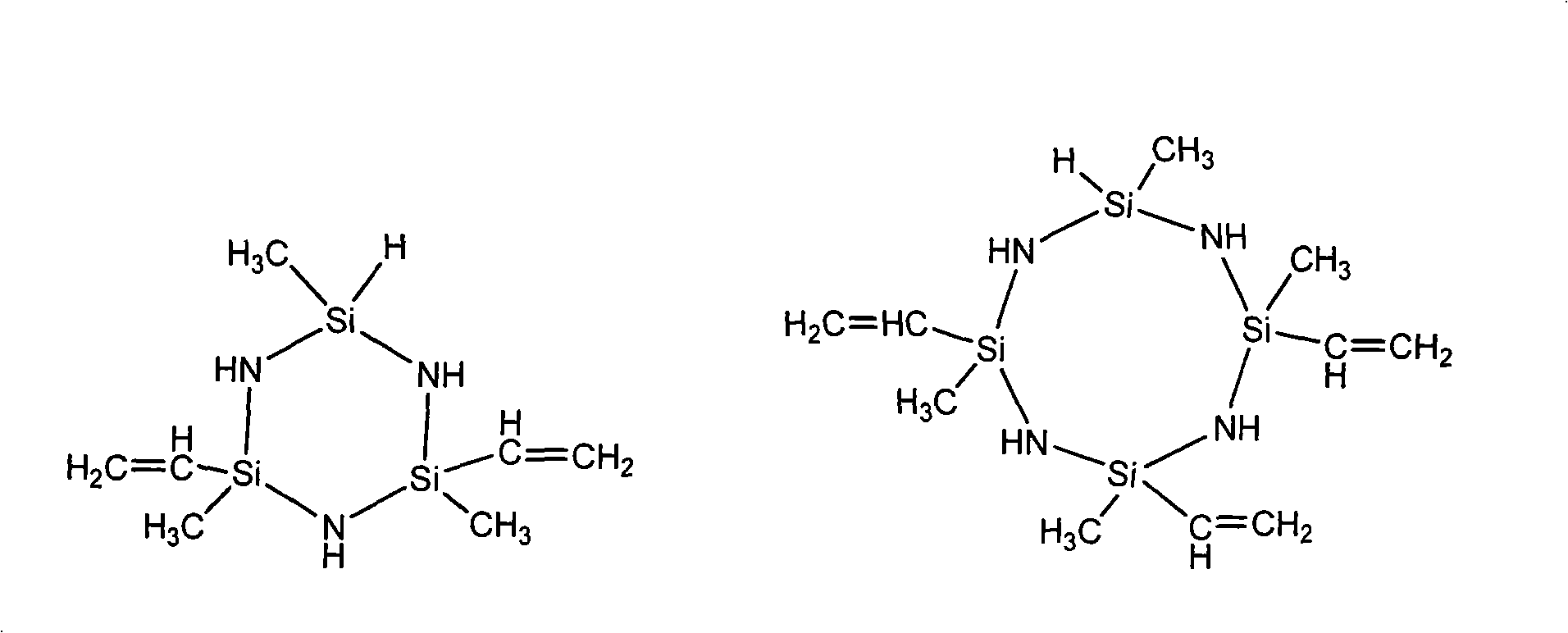

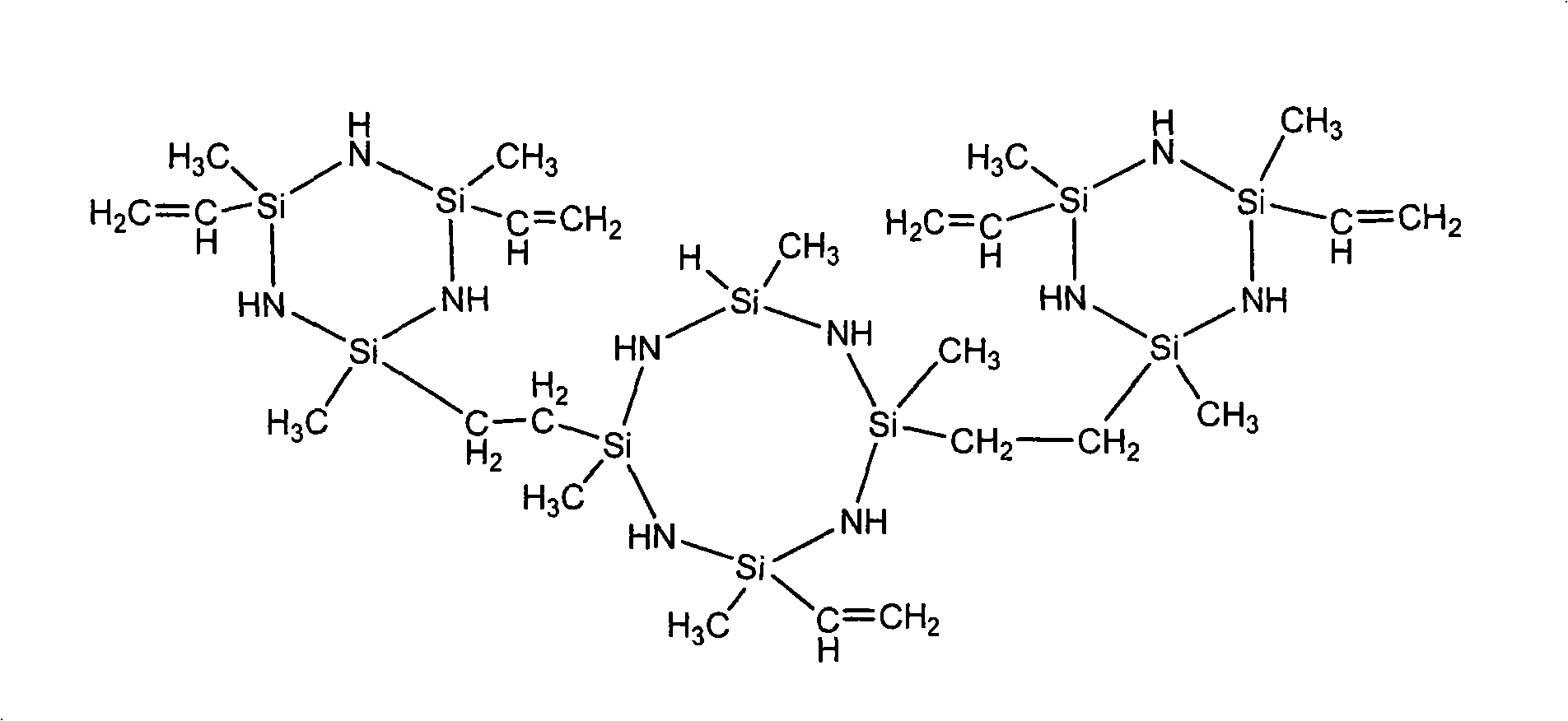

Image

Examples

Embodiment 1

[0023] Example 1: The formula is 0.5 mol (70.5 grams) of methyl vinyl dichlorosilane, 0.15 mol (17.3 grams) of methyl hydrogen dichlorosilane, 500.0 grams of n-hexane, and platinum complex of divinyl tetramethyl disiloxane Compound (platinum content is 0.04mol / L) 0.18 grams.

[0024] Preparation:

[0025] Add the raw materials methylvinyldichlorosilane, methylhydrogendichlorosilane and n-hexane according to the ratio into a 1000mL four-neck flask equipped with a thermometer and a stirrer, put it in an ice-water bath, and start the stirrer to mix the raw materials evenly. Then feed ammonia gas at a flow rate of 15-20 L / h, keep the temperature of the reaction solution at -5°C, and react for 2.5 hours. After the ammonia gas flow was stopped, the ice bath was removed. After the reaction returned to room temperature, the product was filtered to remove the generated salt. The filtrate was de-hexaned at 85°C and 500mmHg, and the solvent was collected for recycling. When no solvent ...

Embodiment 2

[0029] Embodiment 2: formula is methylvinyl dichlorosilane 0.5mol (70.5 grams), methylhydrogen dichlorosilane 0.2mol (23.0 grams), normal hexane 600.0 grams, chloroplatinic acid isopropanol catalyst (platinum content is 0.04 mol / L) 0.18 g.

[0030] Add the raw materials methylvinyldichlorosilane, methylhydrogendichlorosilane and n-hexane according to the ratio into a 1000mL four-neck flask equipped with a thermometer and a stirrer, put it in an ice-water bath, and start the stirrer to mix the raw materials evenly. Then feed ammonia gas at a flow rate of 15-20 L / h, keep the temperature of the reaction solution at -5°C, and react for 2.5 hours. After the ammonia gas flow was stopped, the ice bath was removed. After the reaction returned to room temperature, the product was filtered to remove the generated salt. The filtrate was de-hexaned at 85°C and 500mmHg, and the solvent was collected for recycling. When no solvent flows out, add platinum-based catalyst chloroplatinic acid ...

Embodiment 3

[0034] Example 3: The formula is 0.5 mol (70.5 grams) of methyl vinyl dichlorosilane, 0.2 mol (23.0 grams) of methyl hydrogen dichlorosilane, 500.0 grams of cyclohexane, platinum divinyl tetramethyl disiloxane 0.25 g of the complex (platinum content is 0.04 mol / L).

[0035] Add the raw materials methylvinyldichlorosilane, methylhydrogendichlorosilane and cyclohexane according to the ratio into a 1000mL four-neck flask equipped with a thermometer and a stirrer, put it in an ice-water bath, and start the stirrer to mix the raw materials evenly. Then feed ammonia gas at a flow rate of 15-20 L / h, keep the temperature of the reaction solution at -5°C, and react for 2.5 hours. After the ammonia gas flow was stopped, the ice bath was removed. After the reaction returned to room temperature, the product was filtered to remove the generated salt. The filtrate was de-hexaned at 85°C and 500mmHg, and the solvent was collected for recycling. When no solvent flows out, add the platinum ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com