Expansion node

A technology for expansion joints and expansion zones, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the impact of the surrounding environment of condensate and inspection personnel, and the service life of non-metallic expansion joints Short, reduce the reliability of system equipment and other problems, to achieve the effect of preventing the deposition of solid matter, prolonging the service life, and preventing the accumulation of liquid at the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

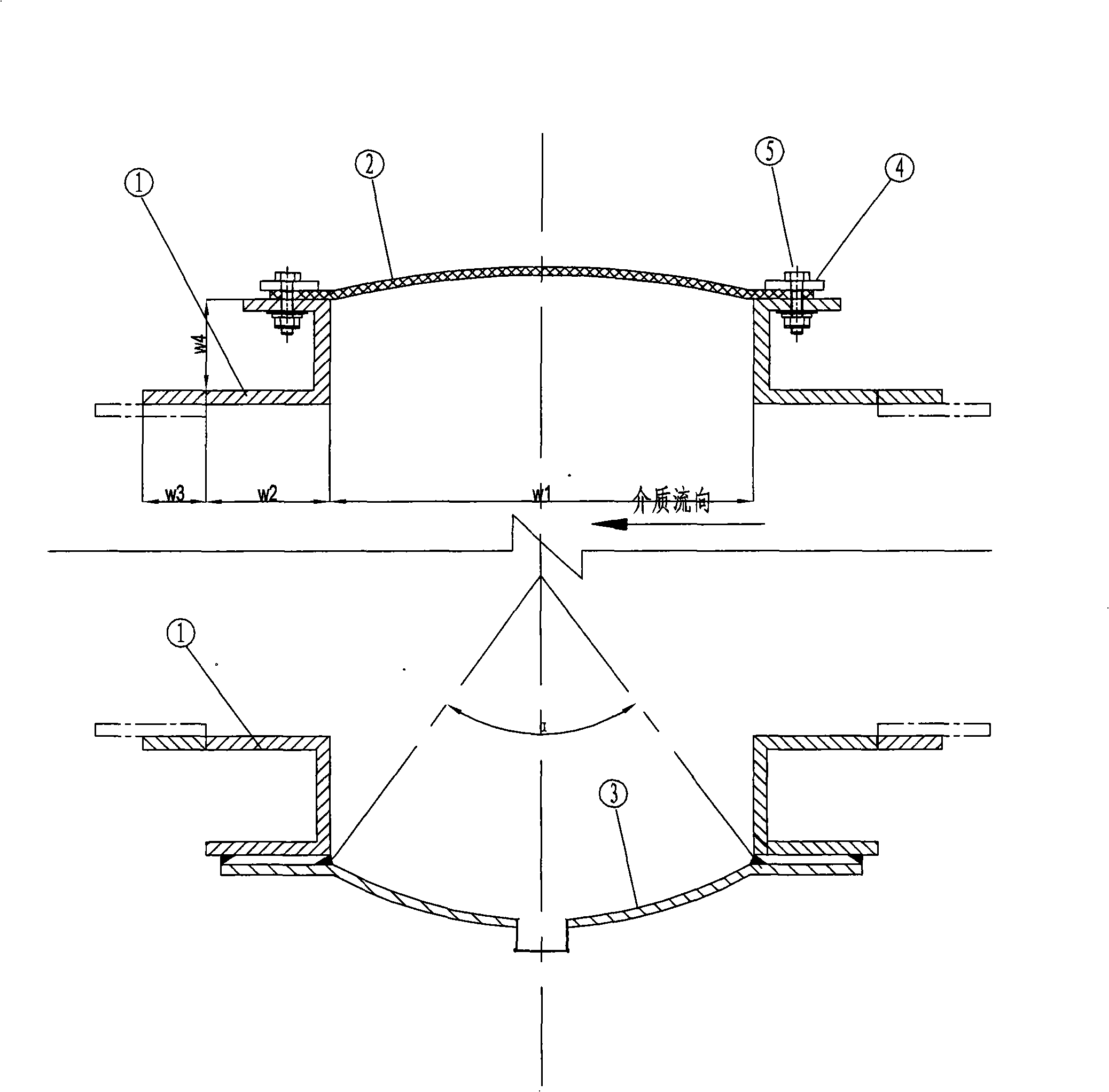

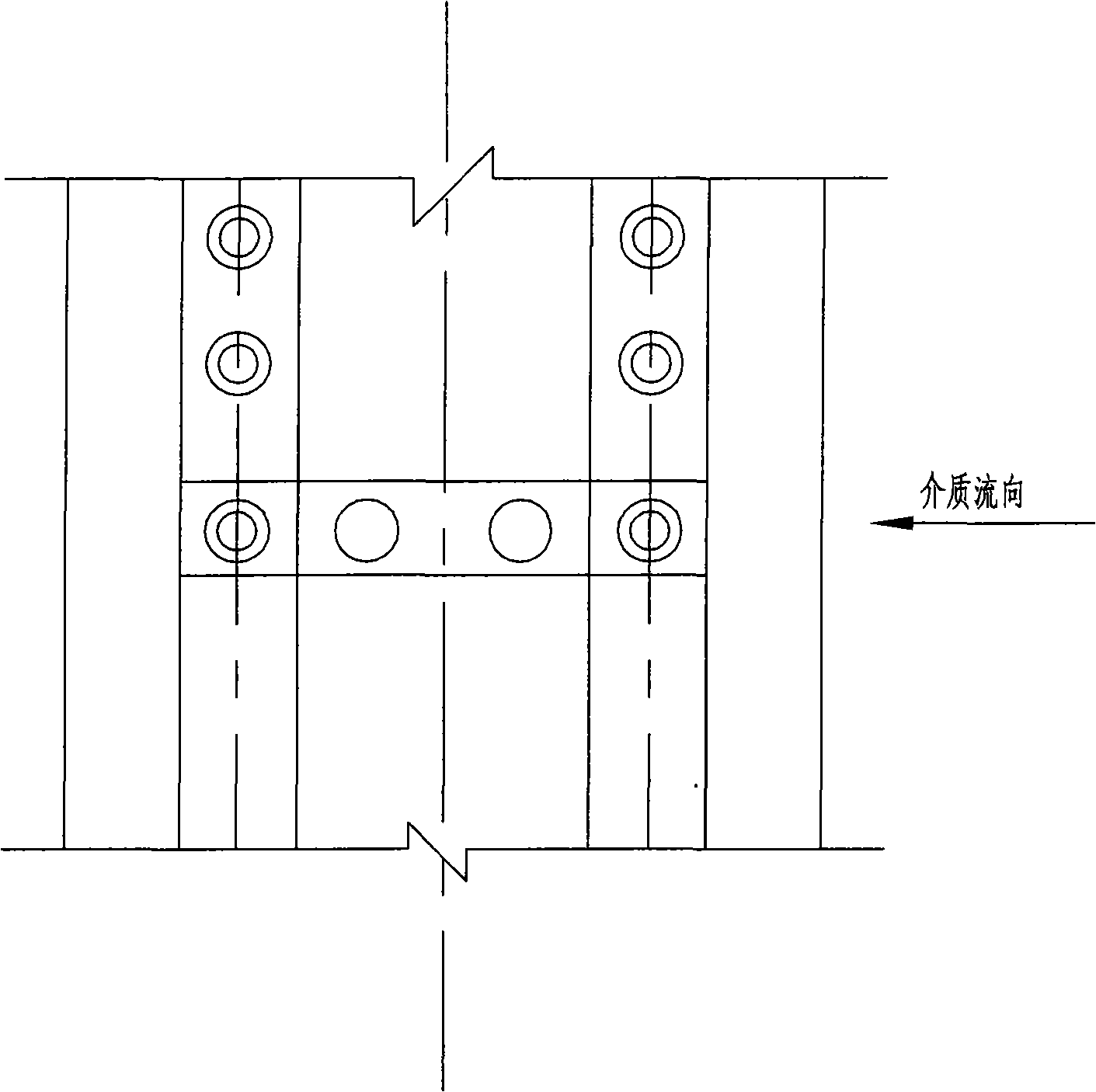

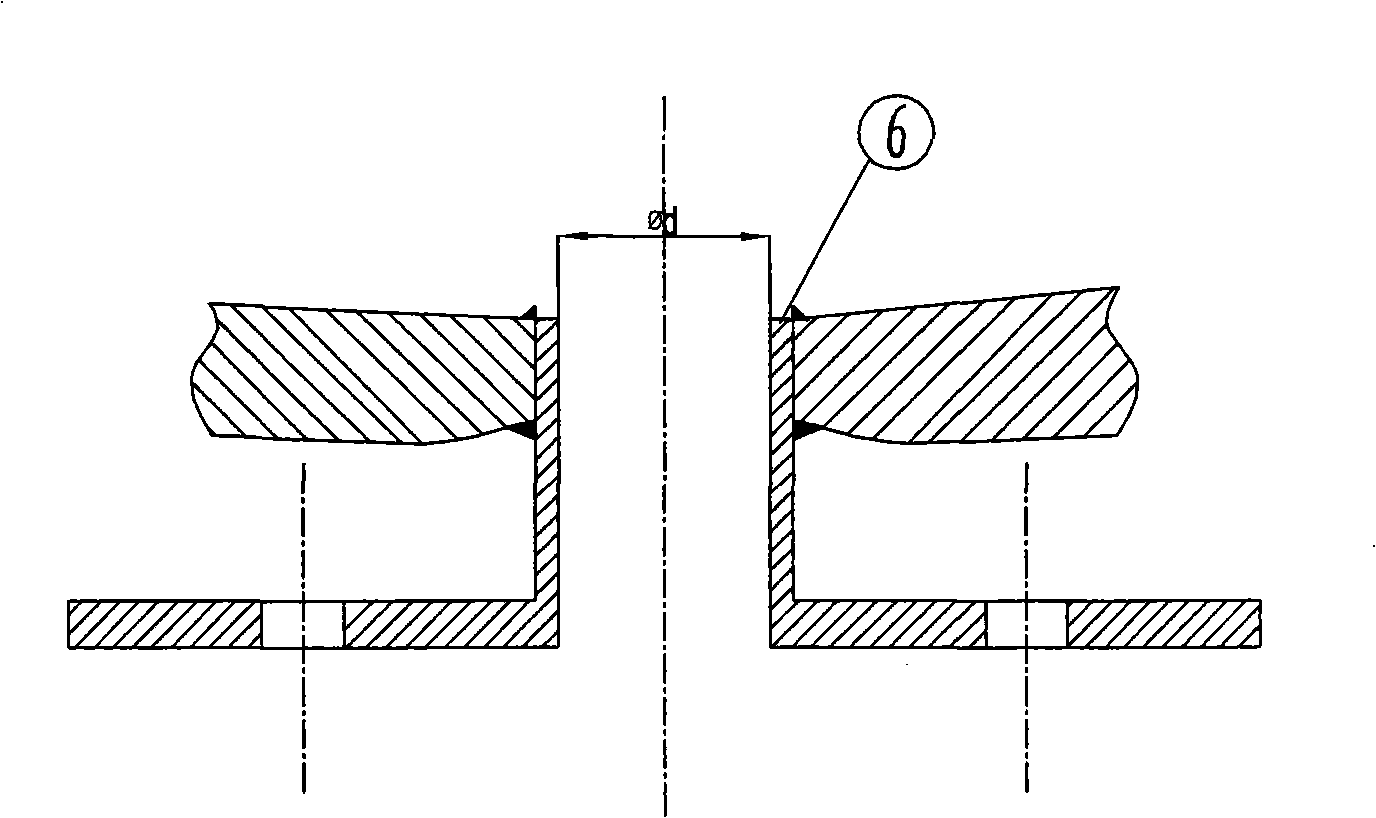

[0021] refer to figure 1 , an expansion joint, including a frame 1, the upper part of the frame 1 is provided with a top telescopic area 2, the lower part is provided with a bottom telescopic area 3, a diversion groove is opened on the bottom telescopic region 3, and a diversion pipe 6 is arranged in the diversion groove, The frame 1 is made of carbon steel, the top telescopic area 2 is made of non-metallic fabric material, the bottom telescopic area 3 is made of alloy material, and the guide tube 6 is made of alloy material. The top telescopic zone 2 is connected to the frame 1 by carbon steel bolts 4 and carbon steel bead 5, and the bottom telescopic zone 3 is connected to the frame 1 by welding. The alloy material is 316 stainless steel or 904 alloy or 926 alloy or C276 alloy. The guide groove is arranged in the middle of the bottom expansion zone 3 . The two ends of the bottom expansion zone 3 are linear, the middle part is an arc segment, and the angle α between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com