High-efficiency solar omnirange condensation battery component

A technology of solar panels and concentrating cells, applied in the field of solar power generation, can solve the problems of complex structure of solar trackers, reduce the amount of battery cells, reduce costs, etc., and achieve the effect of wide application and promotion value, reduction of power generation costs, and reduction of consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

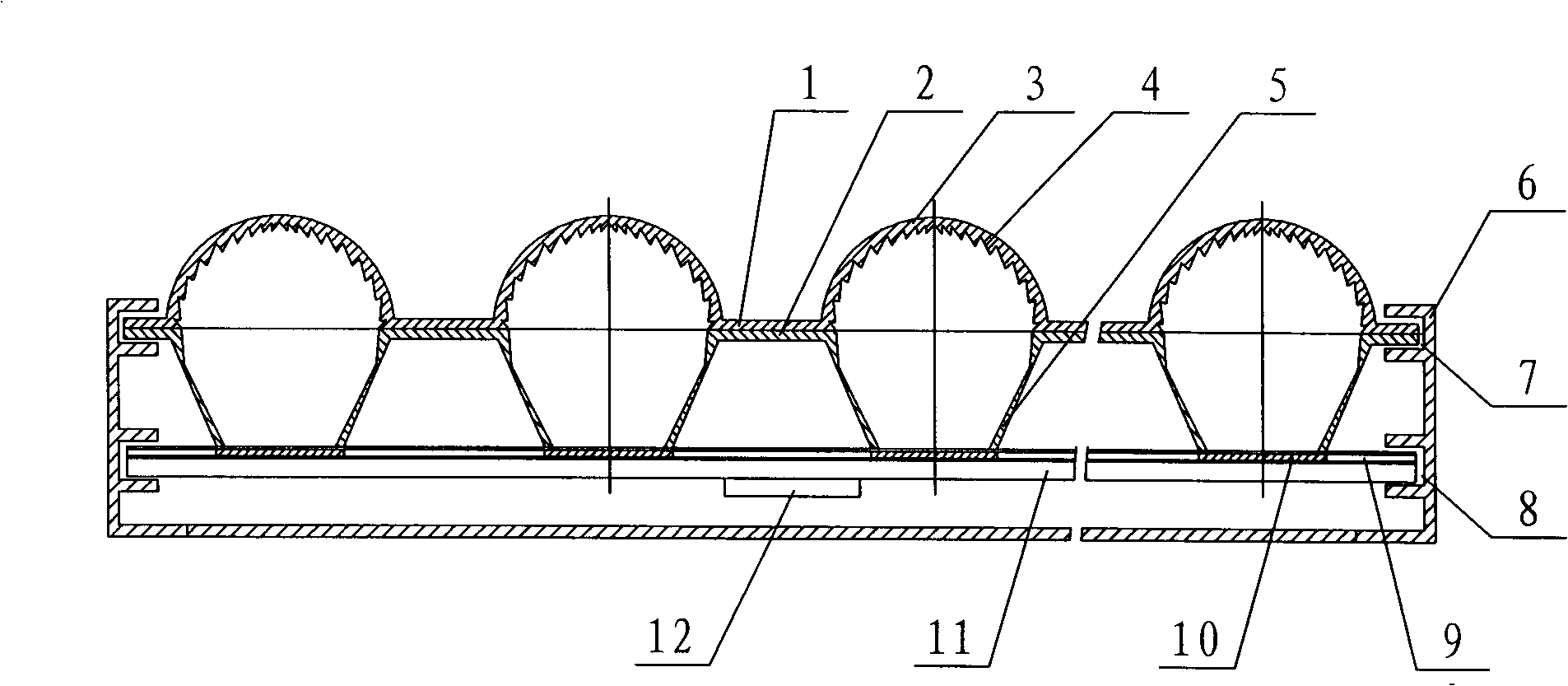

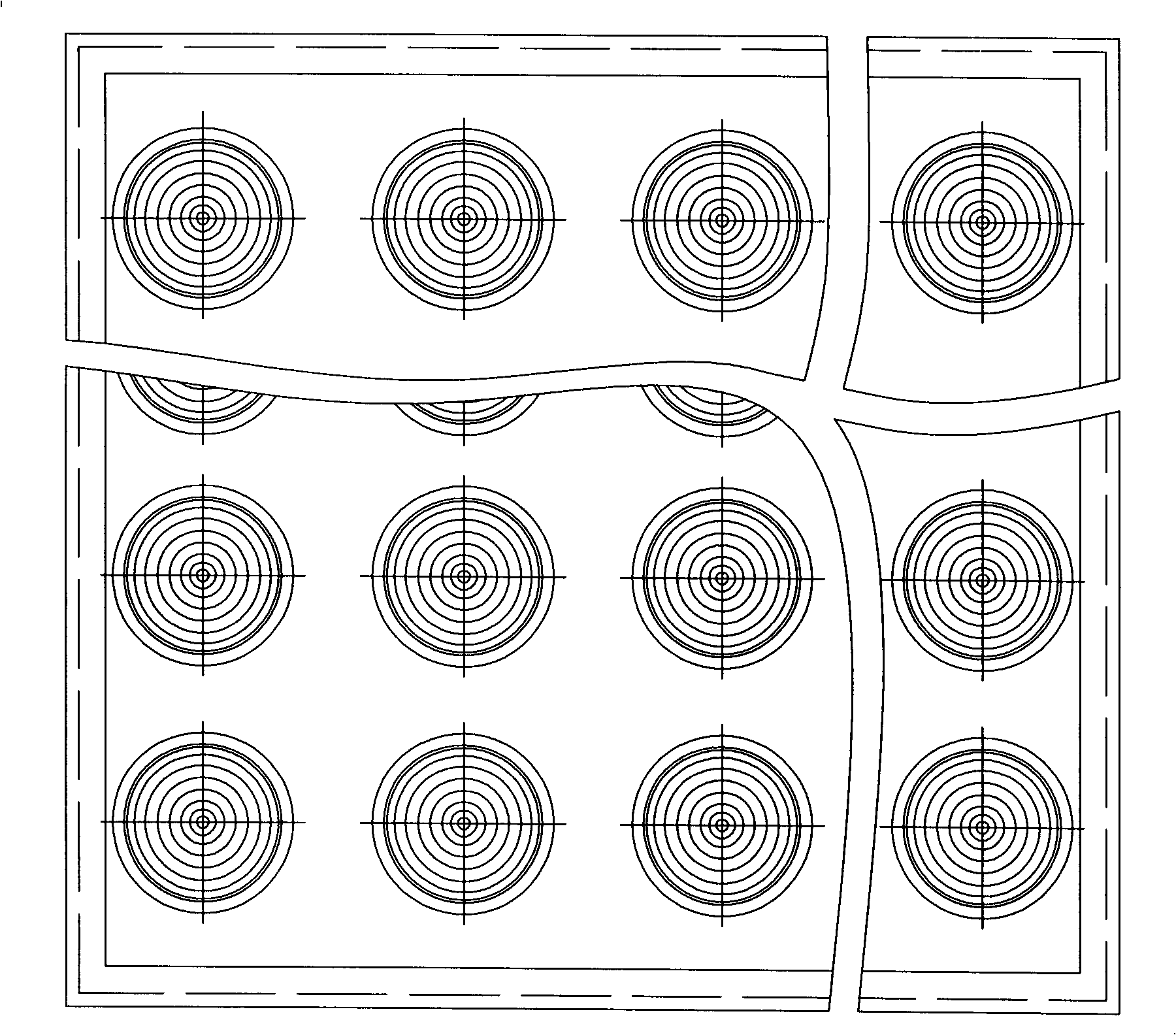

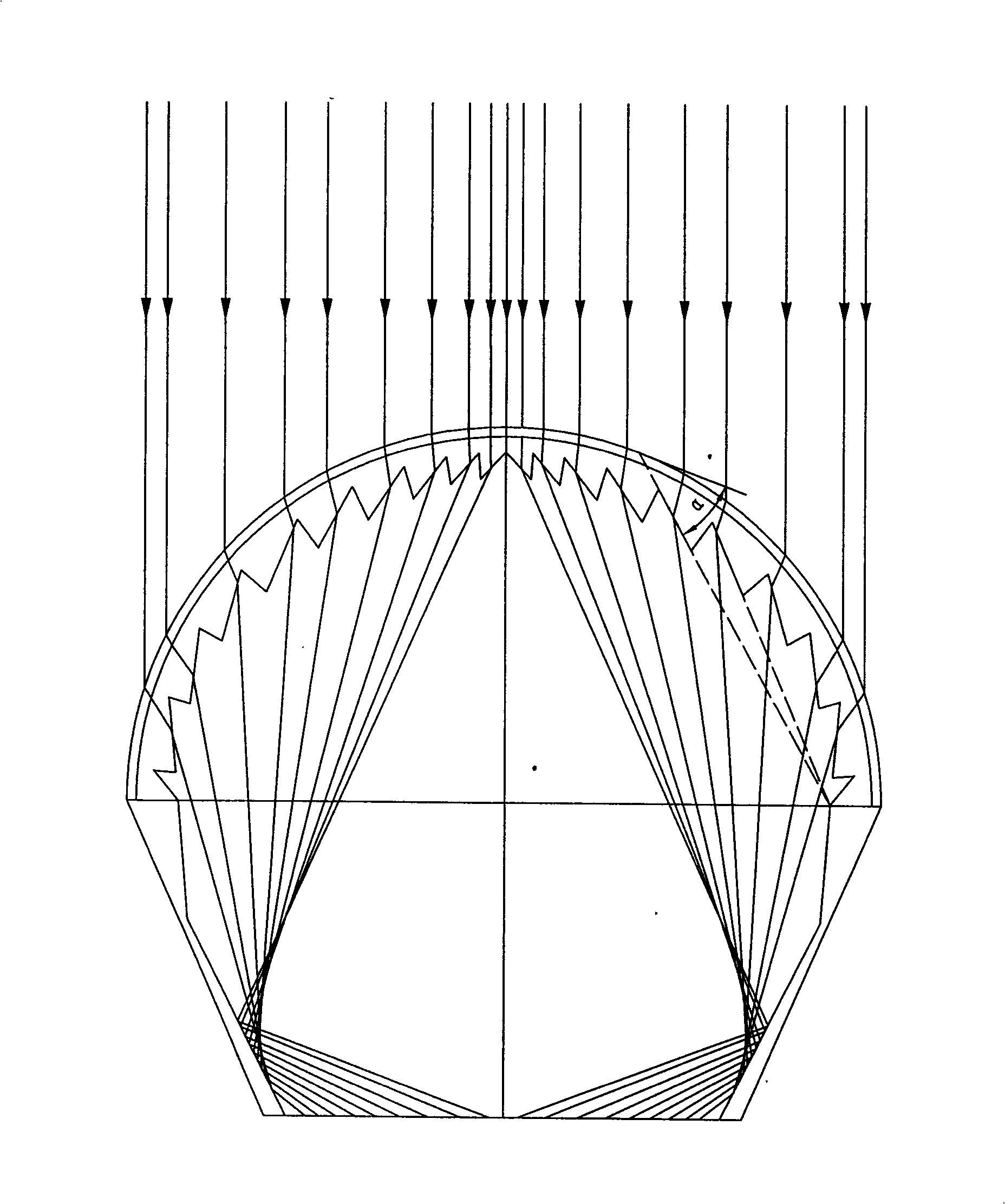

[0014] figure 1 , 2 A high-efficiency solar omnidirectional concentrating cell assembly shown includes a concentrating assembly, a solar cell panel 9, and an outer frame 6. The concentrating assembly includes a concentrating plate 1 and a concentrating plate 2, and several spherical hollow lenses 3 are molded at one time. Or extruded to form a light-collecting plate 1 with several spherical cavity lenses, stretch several light-concentrating funnels 5 with metal materials such as mirror aluminum to form one time, or use aluminum thin plate to stretch and vacuum coat the inside to form a Concentrating plate 2 with several concentrating funnels, the angle formed by the two sides of each concentrating funnel 5 is 30°-55°, several spherical hollow lenses and several concentrating funnels are evenly distributed, spherical hollow lens 3 is convex u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com