Direct foundry connection method for rare-earth permanent magnet motor rotor magnetism-isolating loop

A technology of rare earth permanent magnet motor and connection method, which is applied in the direction of magnetic circuit rotating parts, manufacturing stator/rotor body, magnetic circuit shape/style/structure, etc., and can solve problems such as unfavorable mass production and time-consuming processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

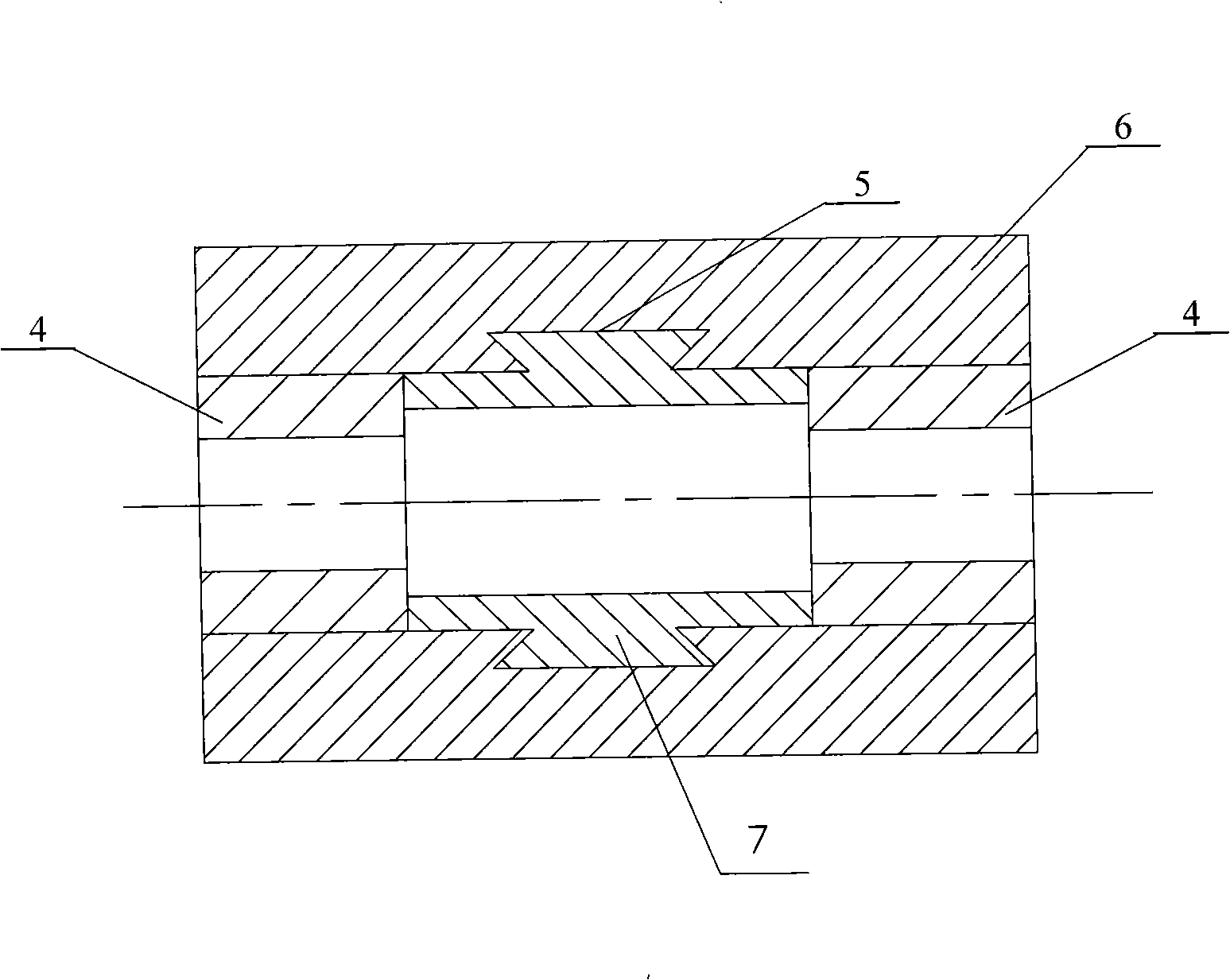

[0005] Specific implementation mode one: the following combination figure 2 This embodiment will be specifically described. This embodiment is realized by the following steps: 1. Process two magnetic isolation ring bodies 4 by turning; 2. Set the two magnetic isolation ring bodies 4 on the two ends of the inner hole of the rotor body 6 respectively; 1. Pouring the molten stainless steel into the space formed by the two magnetic isolation ring bodies 4 and the inner wall of the rotor body 6, so as to solidify into a stainless steel magnetic isolation sleeve 7, and the stainless steel magnetic isolation sleeve 7 is connected with the magnetic isolation ring body 4 respectively. The inner end surface and the inner wall of the rotor body 6 are condensed into one body. The material of the magnetic isolation ring body 4 and the stainless steel magnetic isolation sleeve 7 is 1Cr18Ni9Ti. The advantage of this arrangement is that the same metal is easy to connect.

specific Embodiment approach 2

[0006] Specific implementation mode two: the following combination figure 2 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that: a dovetail ring groove 5 is processed on the inner wall at the middle section of the inner hole of the rotor body 6 . With such arrangement, the molten stainless steel flows into and solidifies in the dovetail ring groove 5 , which can improve the connection strength between the stainless steel magnetic isolation sleeve 7 and the inner wall of the rotor body 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com