Method for viral inactivation by dry heating based on glass transition temperature

A glass transition and virus inactivation technology, applied in heating, disinfection, blood diseases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

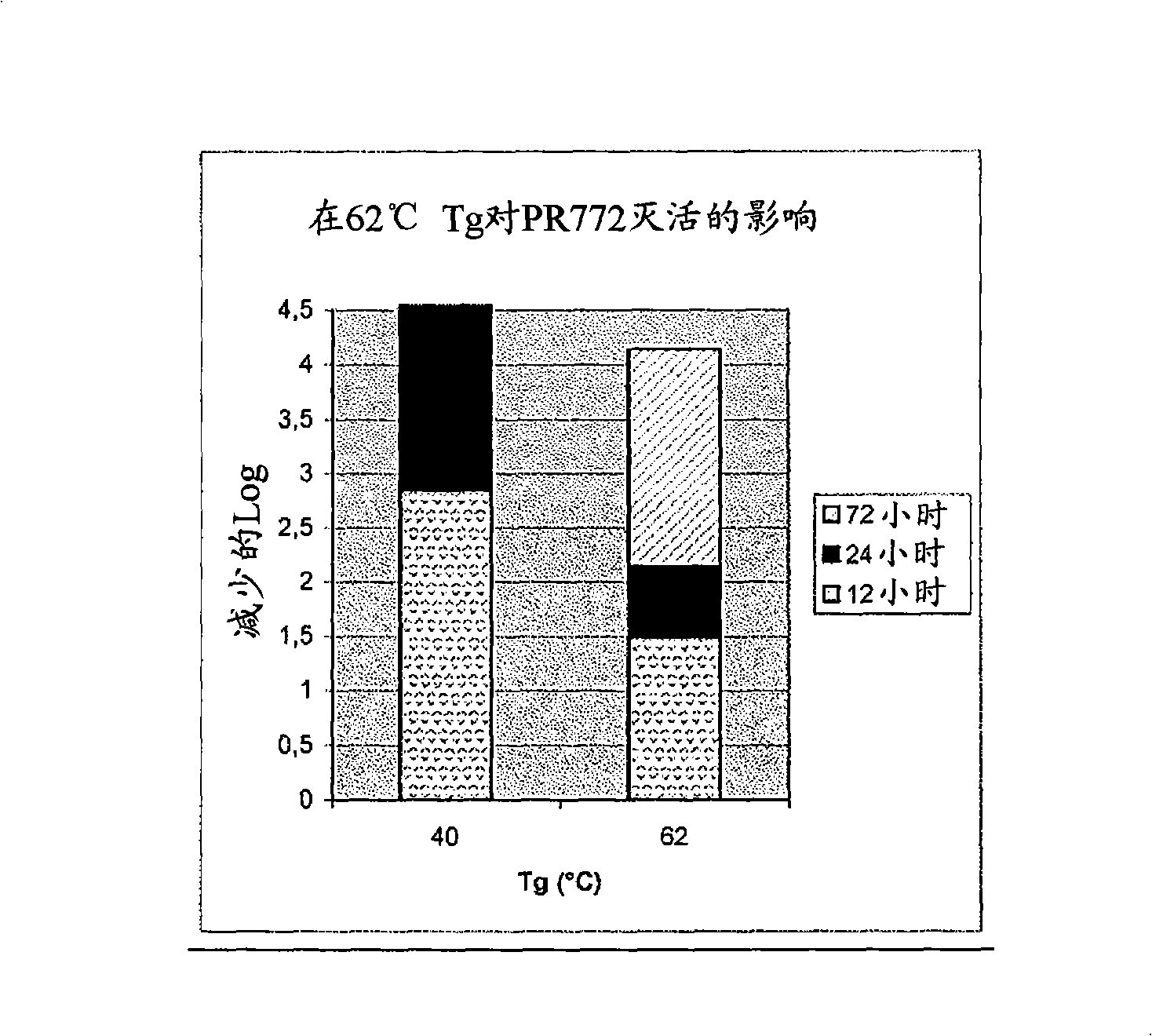

[0075] Embodiment 1: dry heat inactivation of phage PR772 in freeze-dried powder:

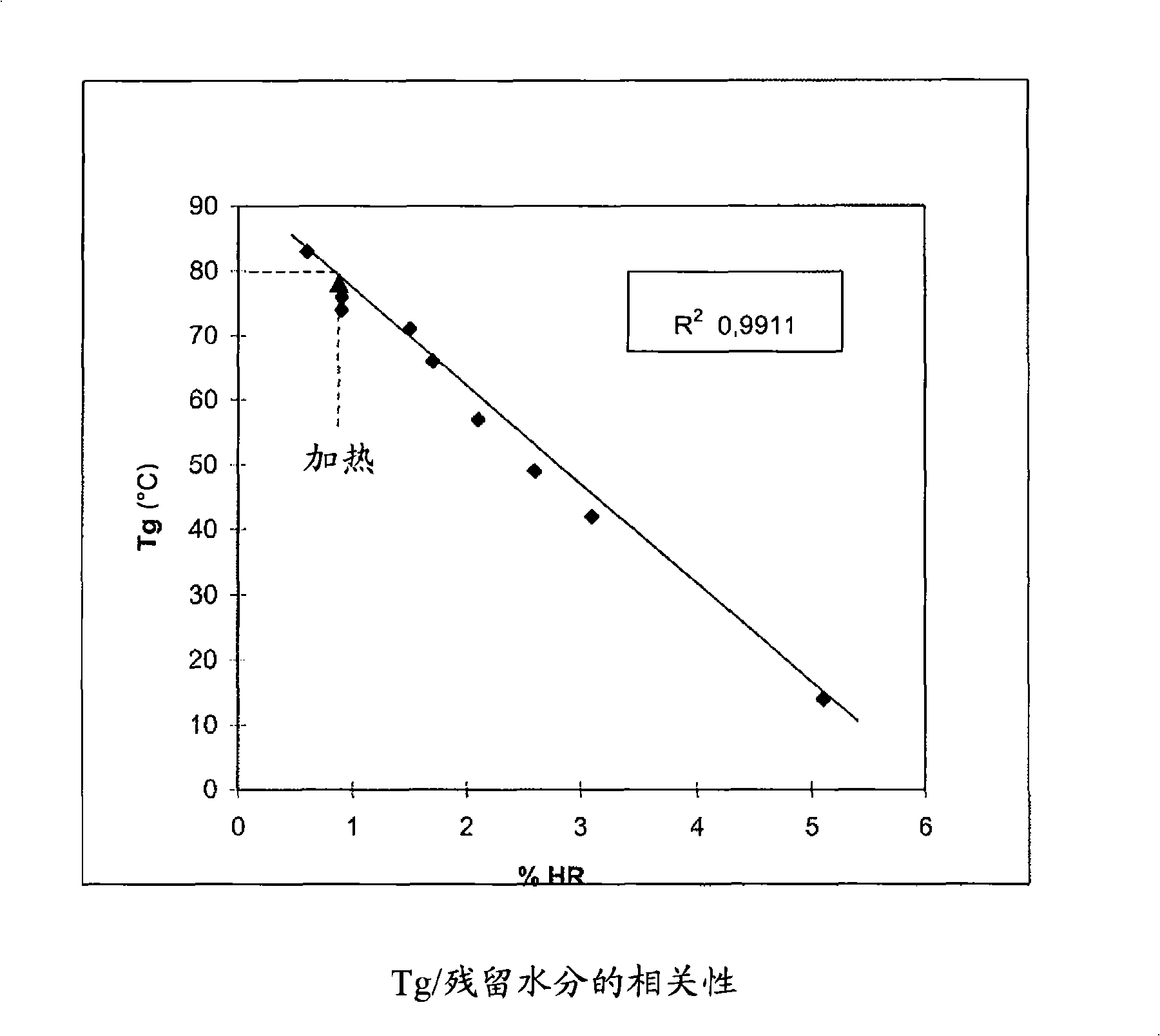

[0076] The physical properties of the lyophilized powder are varied in order to adjust the glass transition temperature (Tg).

[0077] The glass transition temperature was determined using a differential scanning calorimeter. The temperature of the differential scanning calorimeter was calibrated using indium (Tm 156.6°C) and n-octadecane (Tm 28.2°C). The samples were subjected to temperatures from -50°C to 130°C at a rate of change of 20°C / min. Experiments were performed at temperatures below room temperature using liquid nitrogen. The glass transition temperature was taken as the midpoint of the endothermic change in the apparent specific heat. The measurement was performed twice, and the average thereof was taken as Tg.

[0078] Heating is performed at a temperature below Tg (ie, in the solid, glassy state), or at a temperature about 20° C. above Tg (ie, in the viscoelastic [rubber] st...

Embodiment 2

[0118] Embodiment 2: dry heating inactivation of PPV in freeze-dried powder

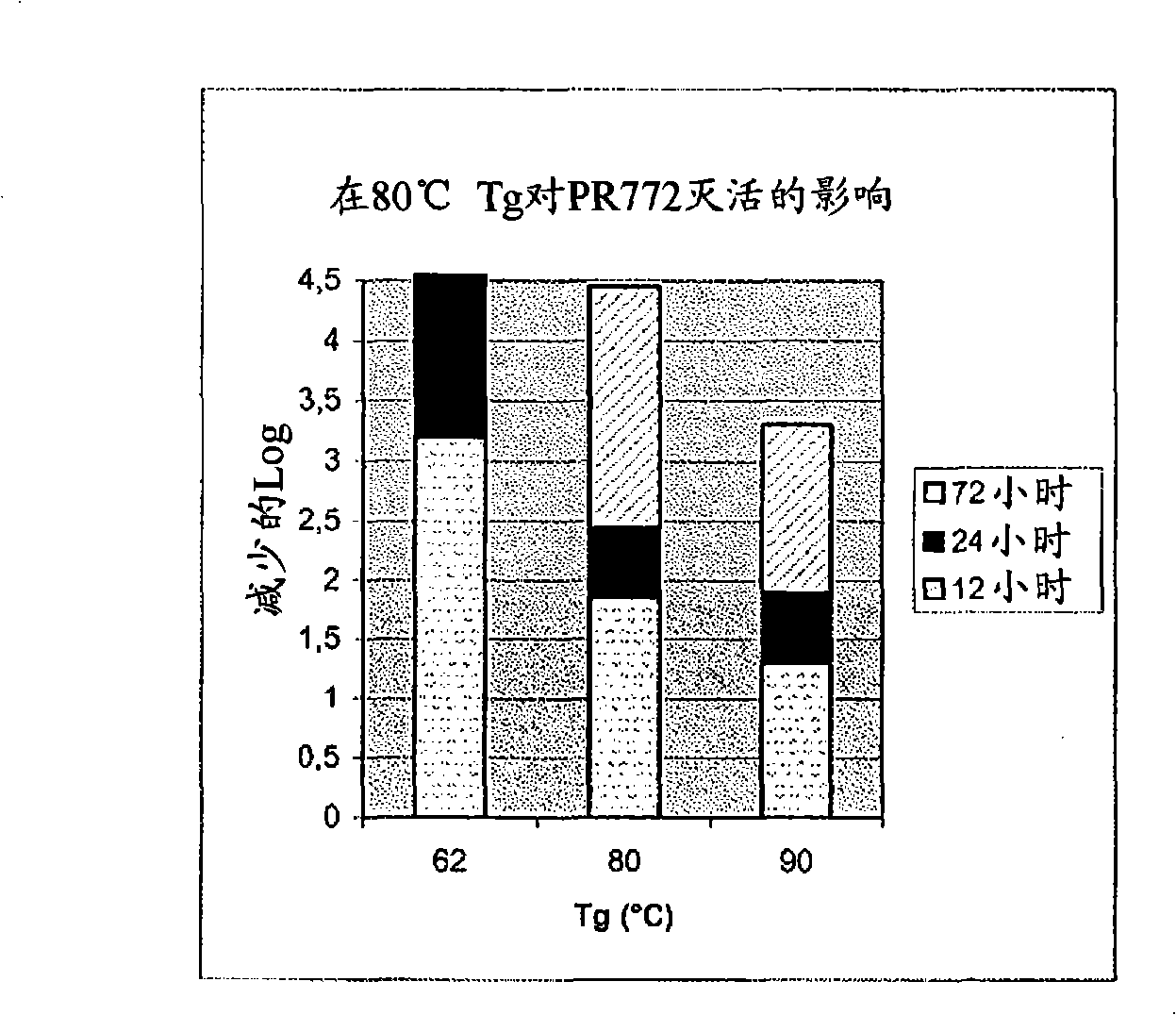

[0119] PPV reduction factors were measured upon heating at 80°C for 12, 24 and 72 hours in lyophilized powders with Tg = 80°C or 90°C.

[0120] The result is as Figure 4 shown in the chart.

[0121] It can be seen that for heating at T=80°C

[0122] - When Tg=T, the reduction factor is close to 4log 10

[0123] - When T10 .

Embodiment 3

[0124] Embodiment 3: PPV, HAV, BVDV, PR772 and Phi174 in the lyophilized powder when T=Tg dry heat inactivation

[0125] PPV, PPV, Reduction factors for HAV, BVDV, PR772 and phage Phil74.

[0126] The result is as Figure 5 and 6 shown in the chart.

[0127] It can be seen that for the less resistant viruses, namely HAV, BVDV and Phi174, heating to T = Tg is sufficient to achieve a reduction factor of 4 log from 24 hours onwards 10 .

[0128] In contrast, for the more resistant viruses, namely PPV and PR772, the heating time had to be extended to 72 hours to achieve a reduction factor close to 4 log 10 .

[0129] As a result, for these highly resistant viruses, since the target is their inactivation, the virus reduction factor and virus inactivation factor can be increased by increasing the difference between T and Tg by increasing the heating temperature T or by decreasing the Tg of the product. live rate.

[0130] In addition, a T-Tg range of 20°C or greater woul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com