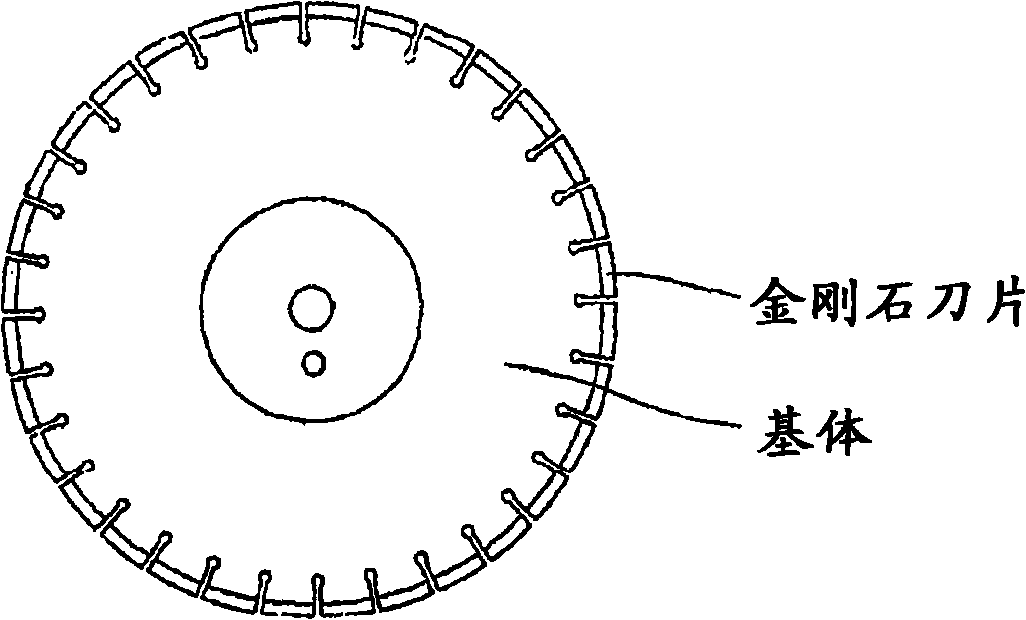

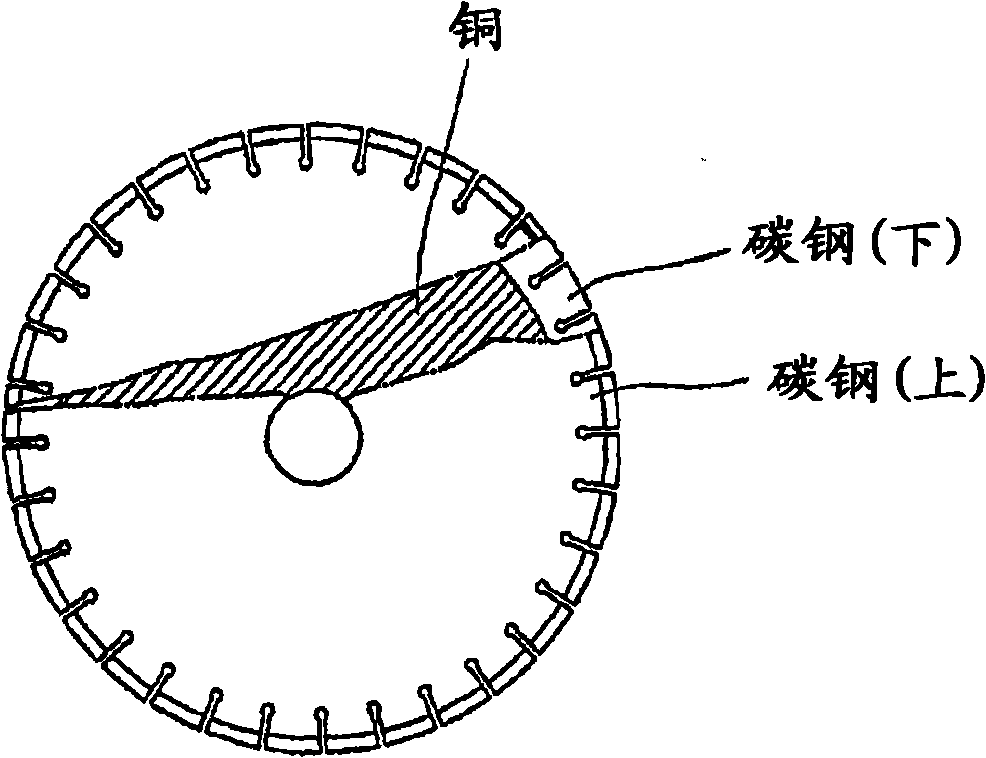

Structure of low noise saw and low noise diamond sawc

A diamond saw, low-noise technology, applied in the direction of sawing machine tools, metal processing equipment, metal sawing equipment, etc., can solve the problems of chipping, limiting cutting depth, and increasing the overall quality of the saw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

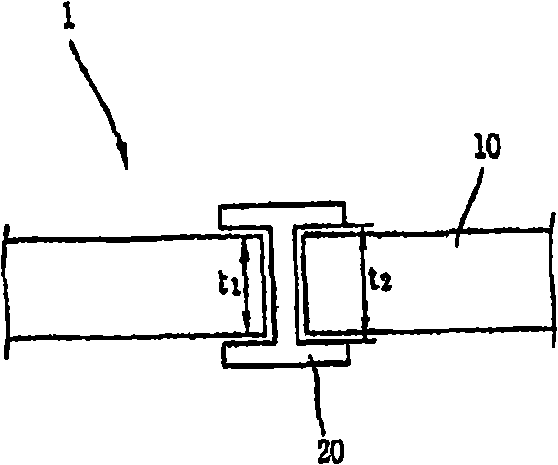

[0027] The present invention provides a saw structure capable of reducing noise generated during cutting operations by installing a damper on a part of a base body.

[0028] image 3 It is a cross-sectional view showing the principle of vibration absorption of the low-noise saw 1 according to the present invention. A hole is formed in the metal plate 10, and a damper 20 in the form of a rivet is inserted into the hole. Here, the vibration absorption capacity depends on the thickness of the metal plate contacting the damper (t 1 ) And the internal distance of the damper (t 2 ) Becomes different.

[0029] In the present invention, a damper in the form of a rivet (2 mm head thickness, 15 mm diameter) is installed on a metal plate (2 mm thickness, 100 mm lateral length, 100 mm longitudinal length), and according to the gap (t 2 -t 1 ) To measure the vibration absorption capacity. in Figure 4 The medium vibration absorption capacity is shown as the specific damping capacity (SDC), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com