Tobacco floating-seedling substrate, preparation method and use thereof

A technology for floating seedling substrate and flue-cured tobacco, which is applied in the directions of botanical equipment and methods, application, soilless cultivation, etc., can solve the problems of environmental pollution, increase the difficulty of fertilization, and high production costs, achieve low cost, and improve resource utilization efficiency. , the effect of protecting non-renewable resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The purple shale is crushed and sieved, and 10 parts of the purple shale with a particle size of 0.5 mm are sterilized at high temperature to prepare a flue-cured tobacco floating seedling-raising substrate. The raw materials used for preparing the flue-cured tobacco floating seedling raising substrate and the weight ratio are:

[0017] 10 parts purple shale

[0018] Organic fertilizer 0 parts

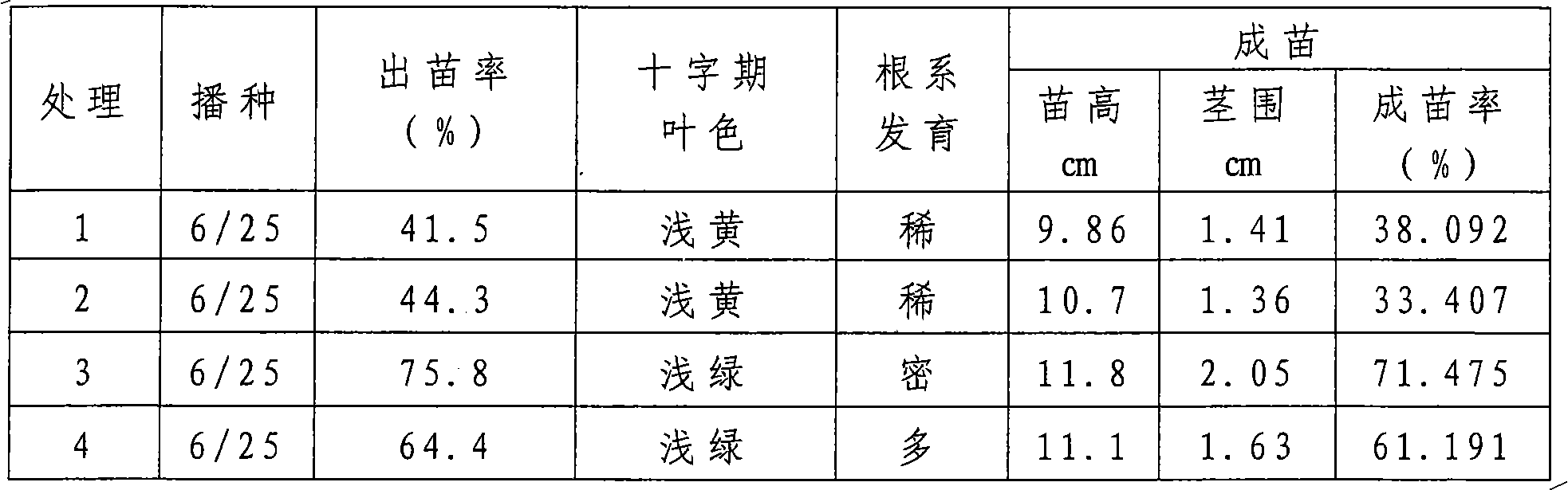

[0019] Using the flue-cured tobacco floating seedling raising substrate of Example 1 above, an effect evaluation test was carried out. The experiment consisted of 4 treatments with 3 repetitions. The 4 treatments are:

[0020] Treatment 1: 10 parts of river sand (particle size 0.5mm) + 0 parts of decomposed organic fertilizer (oil dry)

[0021] Treatment 2: 10 parts of mountain sand (particle size 0.5mm) + 0 parts of decomposed organic fertilizer (oil dry)

[0022] Treatment 3: 10 parts of purple shale (0.5mm particle size) + 0 parts of decomposed organic fertilizer (oil dr...

Embodiment 2

[0030] Crush and sieve the purple shale, fully mix 65 parts of the purple shale with a particle size of 6 mm and 20 parts of the organic fertilizer (chicken manure) that has been decomposed, and then undergo high-temperature sterilization to prepare the flue-cured tobacco floating seedlings. matrix. The raw materials used for preparing the flue-cured tobacco floating seedling raising substrate and the weight ratio are:

[0031] Purple Shale 65 parts

[0032] 20 servings of organic fertilizer

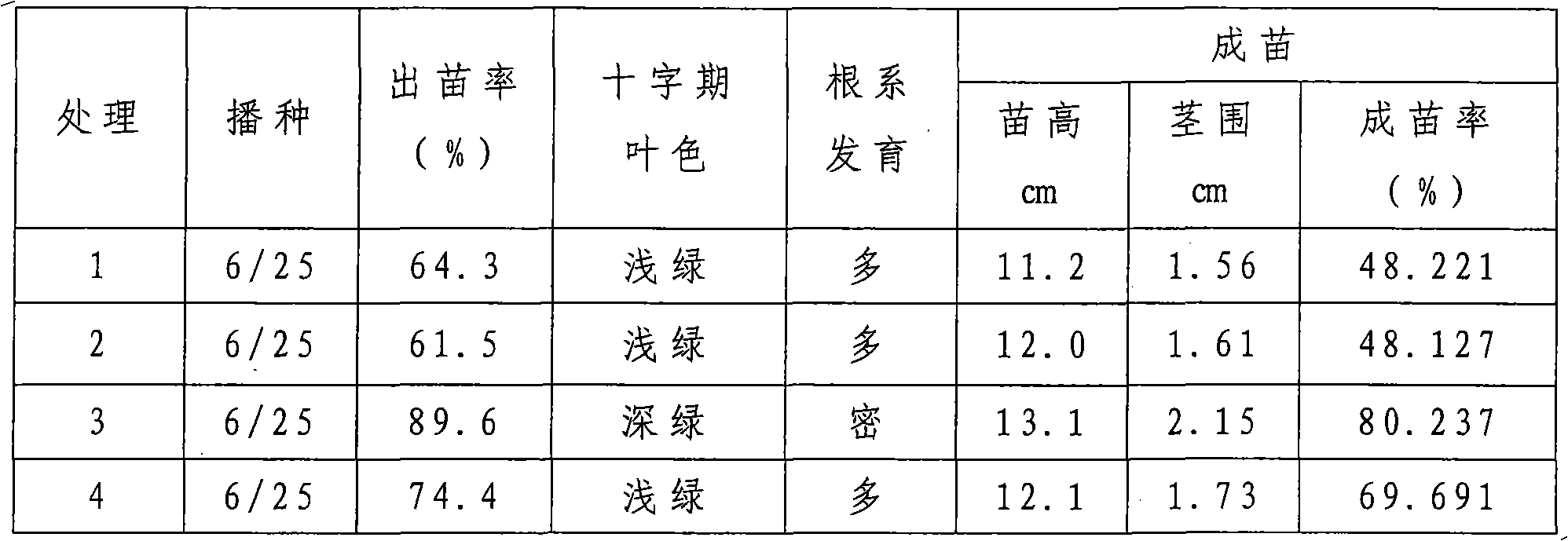

[0033] Using the flue-cured tobacco floating seedling raising substrate of the above-mentioned embodiment 2, an effect evaluation test was carried out. The experiment consisted of 4 treatments with 3 repetitions. The 4 treatments are:

[0034] Treatment 1: 65 parts of river sand (6mm particle size) + 20 parts of decomposed organic fertilizer (chicken manure)

[0035] Treatment 2: 65 parts of mountain sand (6mm particle size) + 20 parts of decomposed organic fertilizer (chicken manur...

Embodiment 3

[0044] Crush and sieve black shale, mix 30 parts of black shale with a particle size of 3mm and 10 parts of decomposed organic fertilizer (pig manure), and then sterilize and disinfect with chemical agent hydrogen peroxide (hydrogen peroxide) , to prepare the flue-cured tobacco floating seedling culture substrate. The raw materials used for preparing the flue-cured tobacco floating seedling raising substrate and the weight ratio are:

[0045] 30 parts black shale

[0046] 10 servings of organic fertilizer

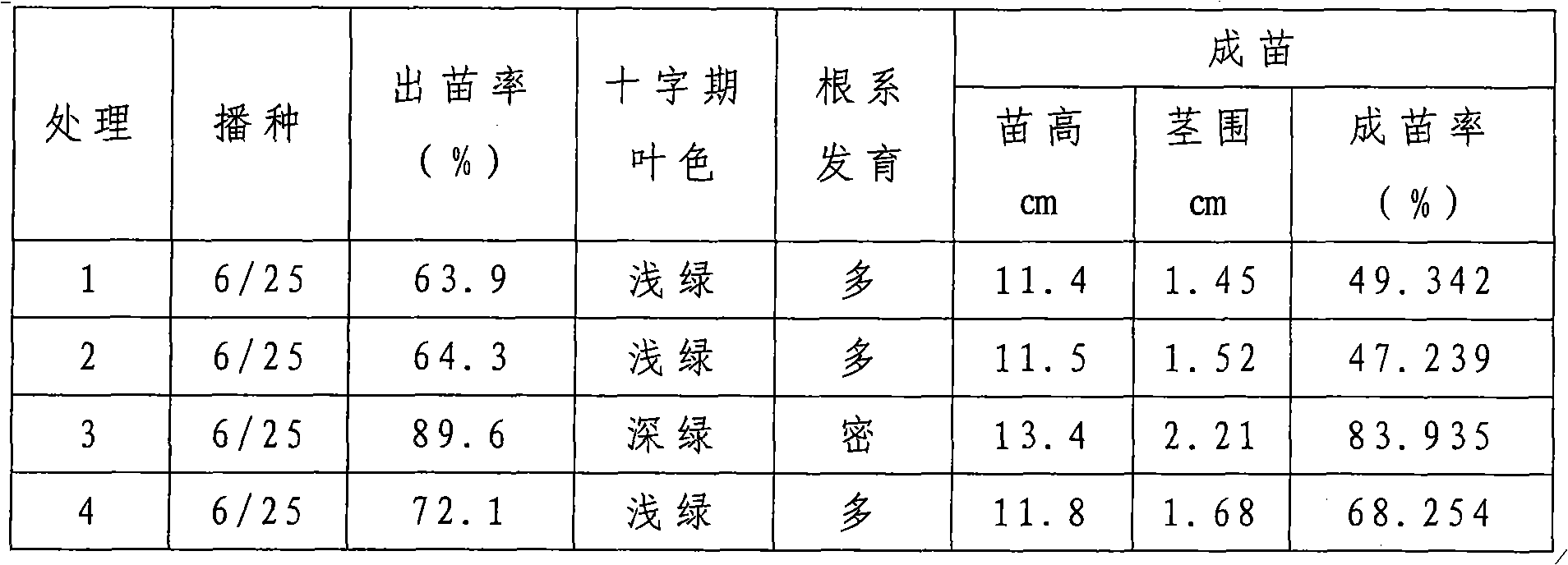

[0047] Using the flue-cured tobacco floating seedling raising substrate of Example 3 above, an effect evaluation test was carried out. The experiment consisted of 4 treatments with 3 repetitions. The 4 treatments are:

[0048] Treatment 1: 30 parts of river sand (3mm particle size) + 10 parts of decomposed organic fertilizer (pig manure)

[0049] Treatment 2: 30 parts of mountain sand (3mm particle size) + 10 parts of decomposed organic fertilizer (pig manure)

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com