Continuous two-step reaction process and its device

A technology of reaction and process, which is applied in the field of continuous two-step reaction process and its device, can solve the problems of low efficiency, non-continuity of two-step reaction, and inapplicability to industrial production, so as to improve space-time yield, avoid separation problems, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] CH 4 -CO 2 Two-step reaction step conversion direct synthesis of C 2 - Oxygenate improvements. CH 4 and CO 2 Co-activation and conversion is one of the most challenging topics in the field of catalysis integrating resources, energy and environmental protection. The present invention is very suitable for the above two-step reaction system.

[0039] Reaction principle: This process is a heterogeneous catalytic reaction system, and the catalyst (which can be regarded as an intermediate substance) is Co-Pd / TiO 2 , where TiO 2 as the carrier, Co and Pd as the catalytically active components, first catalytically activate CH 4 for CH X form, then pass into the CO 2 Carry out intercalation reaction to generate acetate group, generate acetic acid and ethanol after supplementing hydrogen.

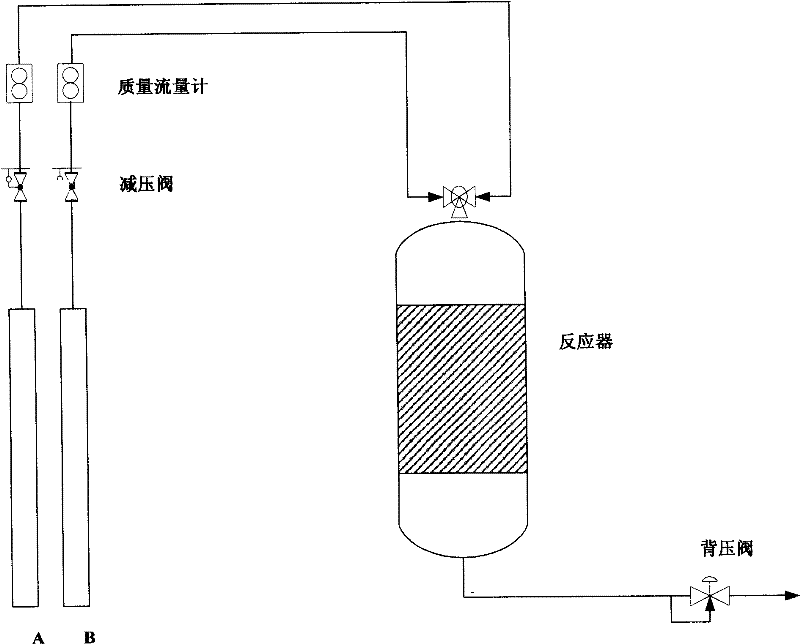

[0040] Utilize device 1 of the present invention to carry out the small-scale experiment of this technique in laboratory, process flow sheet is as attached Figure 4 , solenoid valve...

Embodiment 2

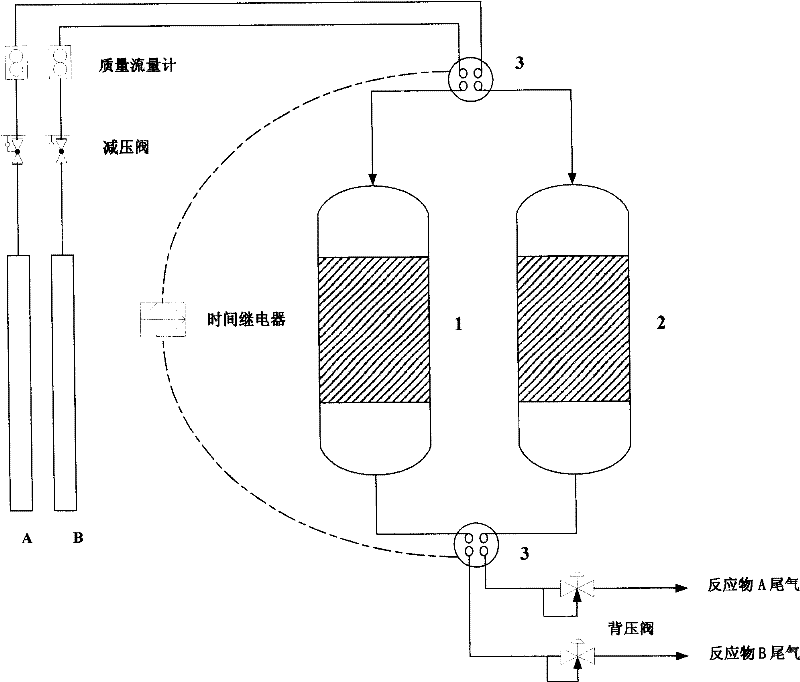

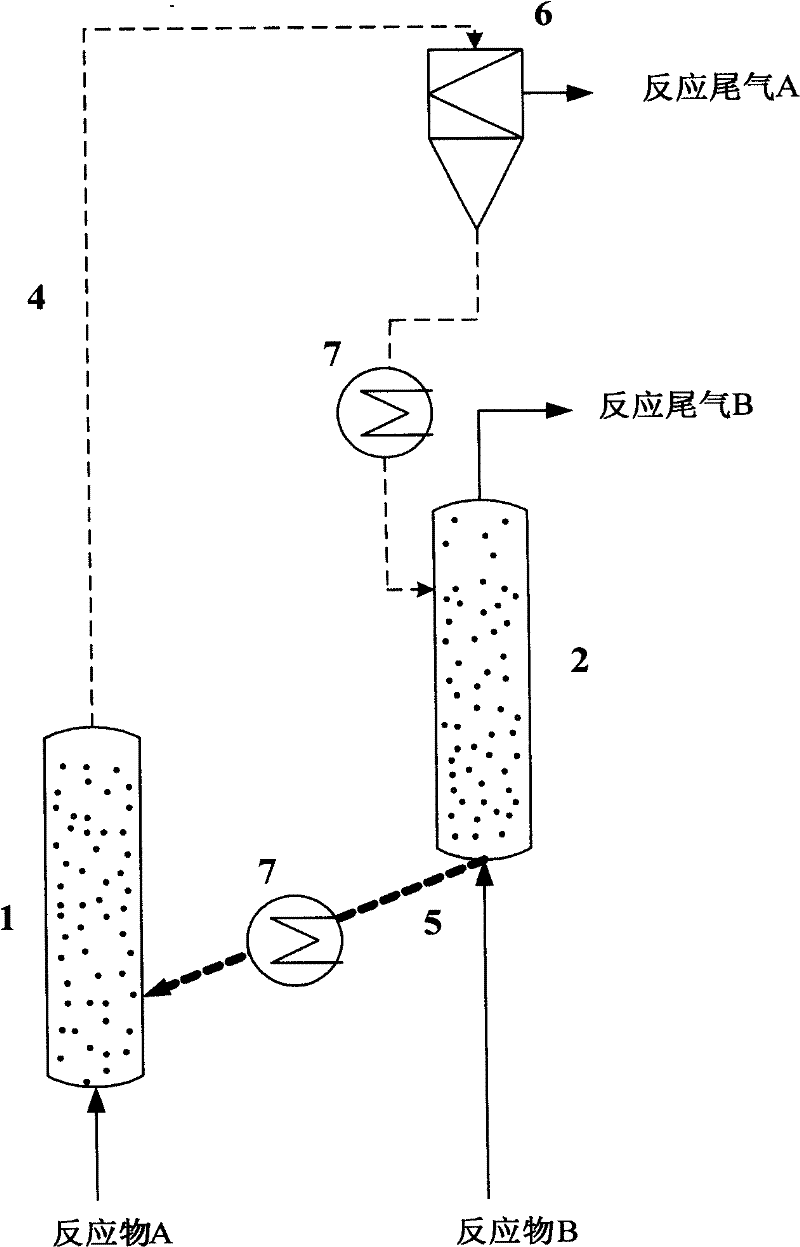

[0044] Utilize device 2 of the present invention to carry out above-mentioned CH in the laboratory 4 -CO 2 The improvement experiment of the two-step reaction step conversion process, the process flow chart is attached Figure 5 , Reactors A and B are circulating beds, in which the catalyst is in a fluidized state, and the circulating beds A and B have a positioning difference. To illustrate from left to right, the hydrogen gas is decompressed and divided into two paths, and the flow rate is adjusted by the flow meter to connect with CH 4 and CO 2 mix, CH 4 First pass through the pressure reducing valve to reduce the pressure, then adjust the flow rate through the mass flow meter, enter the preheater, mix with hydrogen and water vapor, and then enter the circulating bed A for CH 4 activation of CO 2 After being decompressed by the pressure reducing valve, the flow rate is adjusted by the mass flow meter and then enters the preheater to mix with hydrogen and water vapor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com