Pressing device closed-cycle control system

A closed-loop control, press technology, applied in general control systems, presses, control/regulation systems, etc., can solve problems such as unfavorable working modes, backwardness, unsatisfactory efficiency and accuracy, and improve work efficiency. Arrangement, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

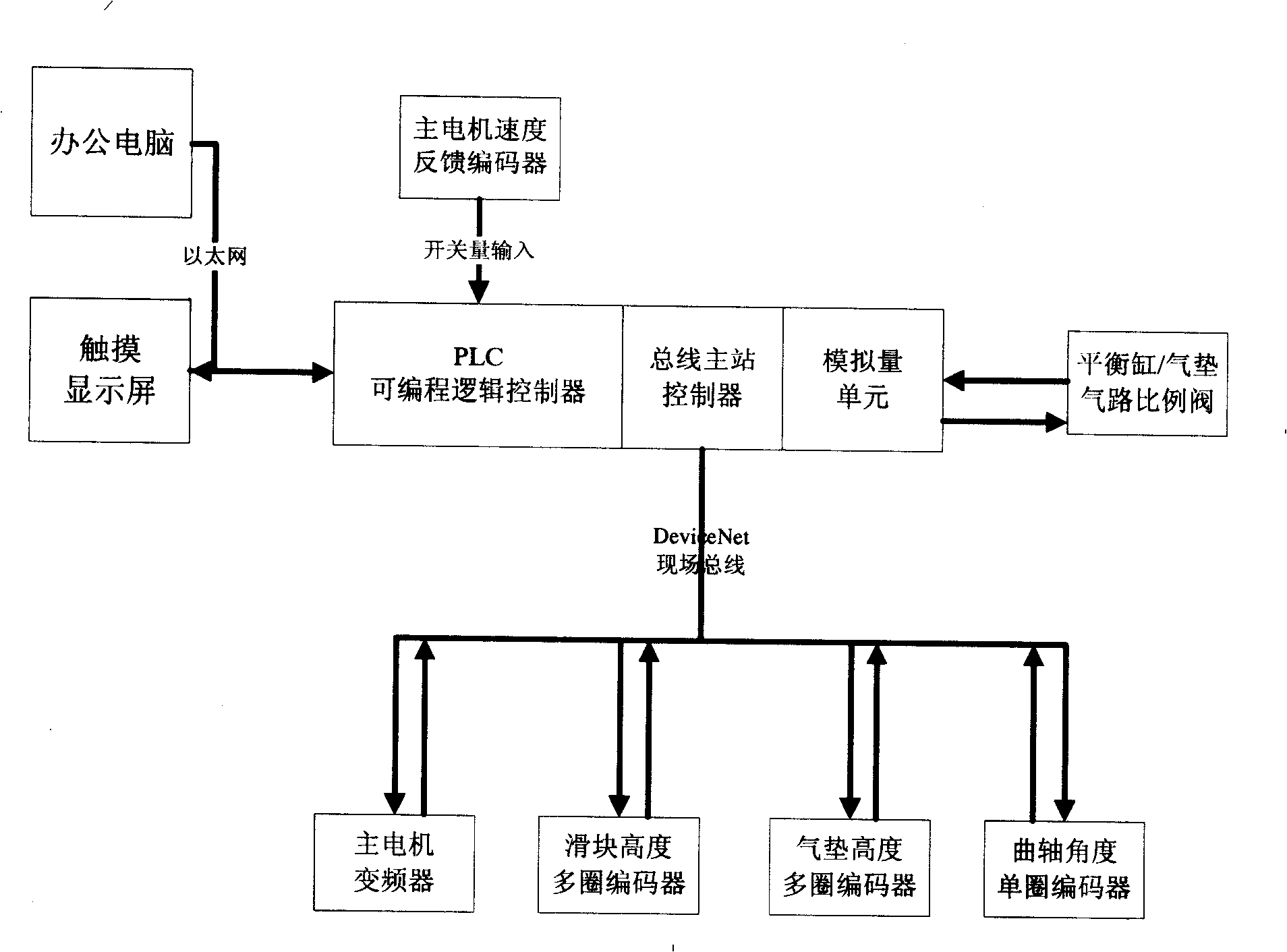

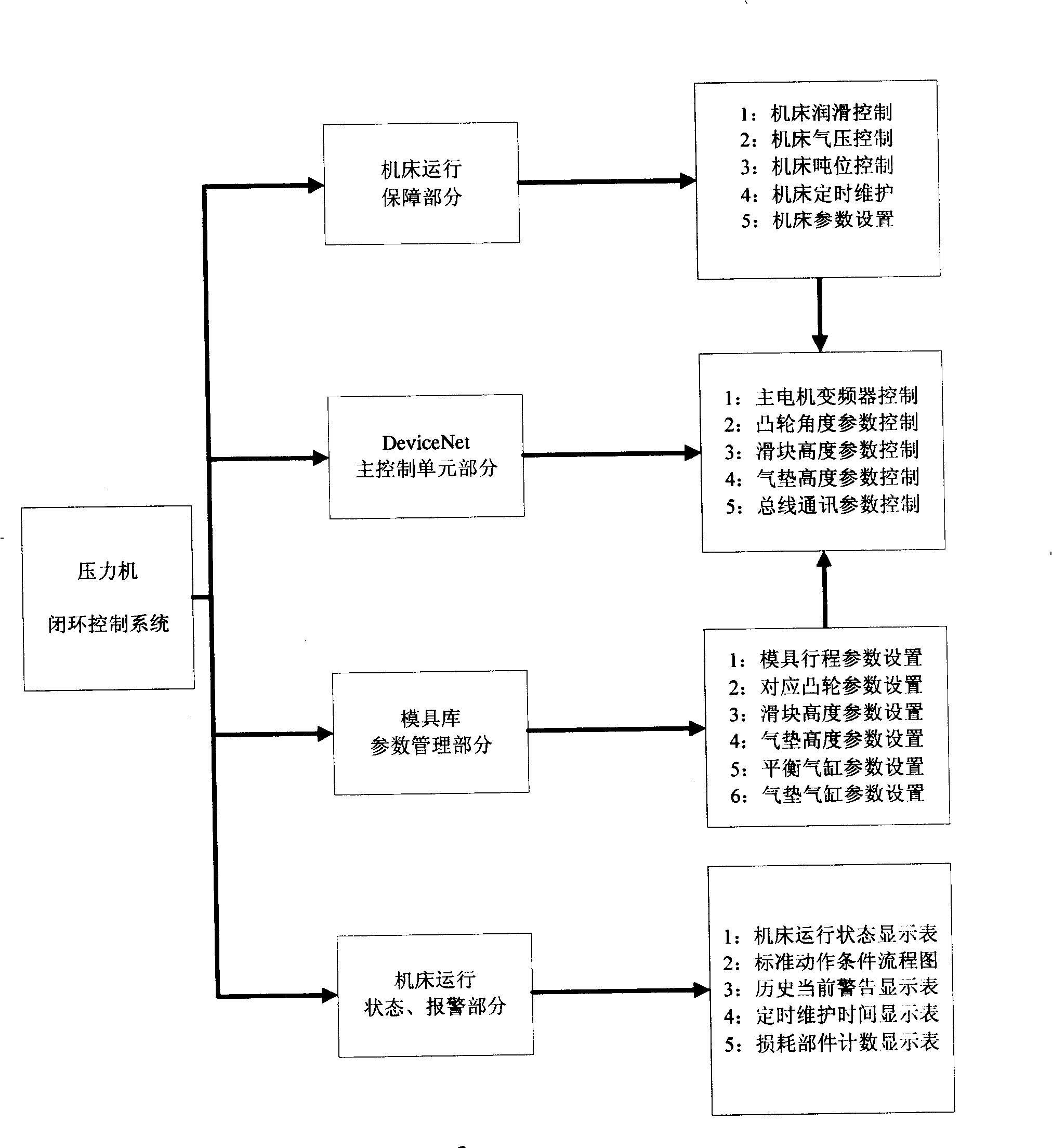

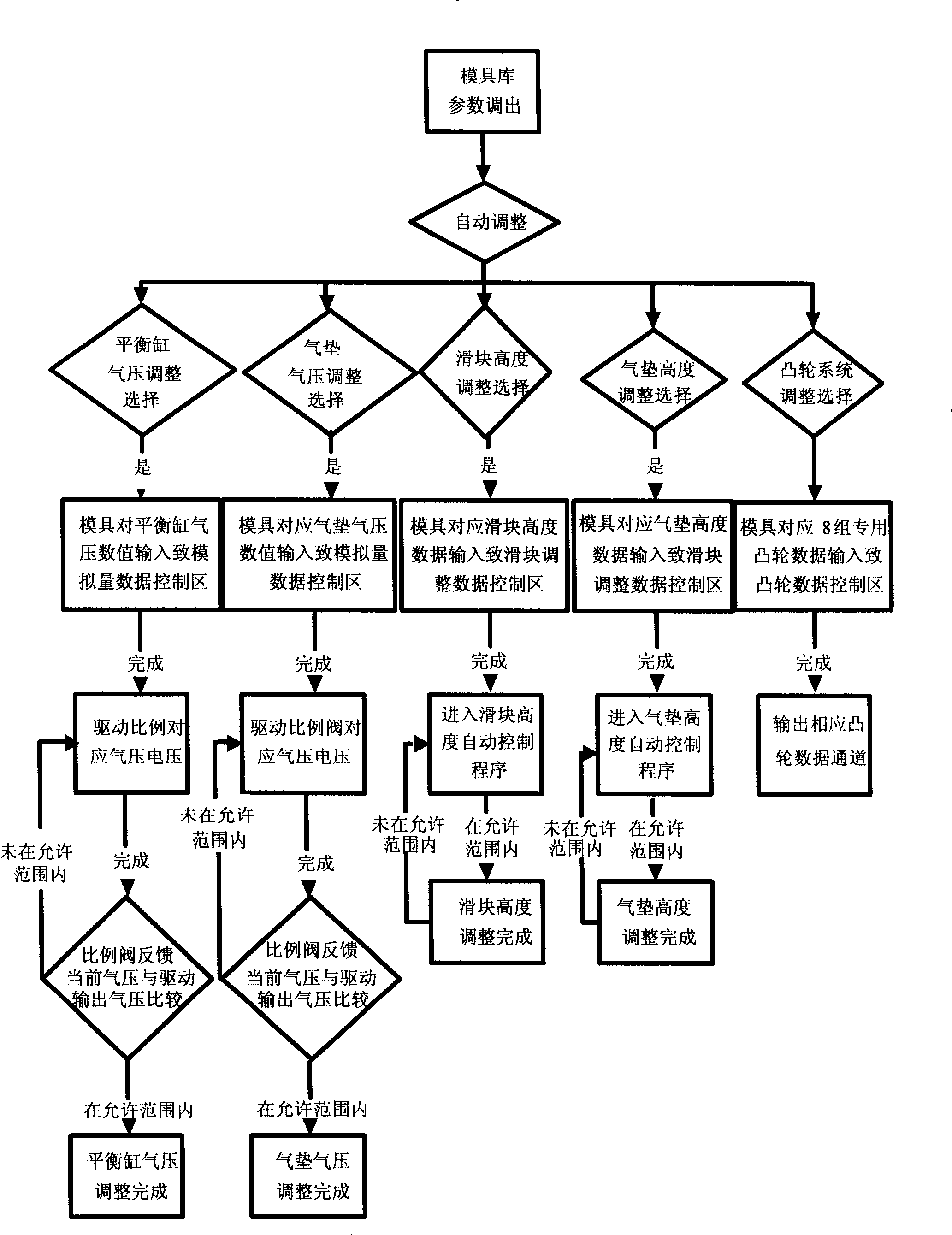

[0018] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the present invention includes a press, a PLC programmable logic controller of the press, a touch screen and an office computer, a main motor of the press, and the speed feedback of the main motor of the press is connected to the PLC programmable logic through the high-speed pulse signal of the incremental encoder. At the input end of the controller, the air pressure of the press balance cylinder, air storage cylinder and air cushion air storage cylinder is precisely controlled through the proportional valve, and the proportional valve exchanges data through the analog unit and the PLC programmable logic controller; the frequency converter of the main motor, and the slider The blind hole type multi-turn absolute value encoder with flexible connection to the drive shaft, the blind hole type multi-turn absolute value encoder with flexible connection with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com