Neoprene adhesive preparation method

A neoprene and adhesive technology, applied in the direction of chloroprene adhesives, adhesives, adhesive types, etc., can solve the problems of not being able to pass through the gear pump, difficulty in normal operation of the device, shortening the dissolution time, etc., to achieve Not easy to stratify, improve efficiency, good dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

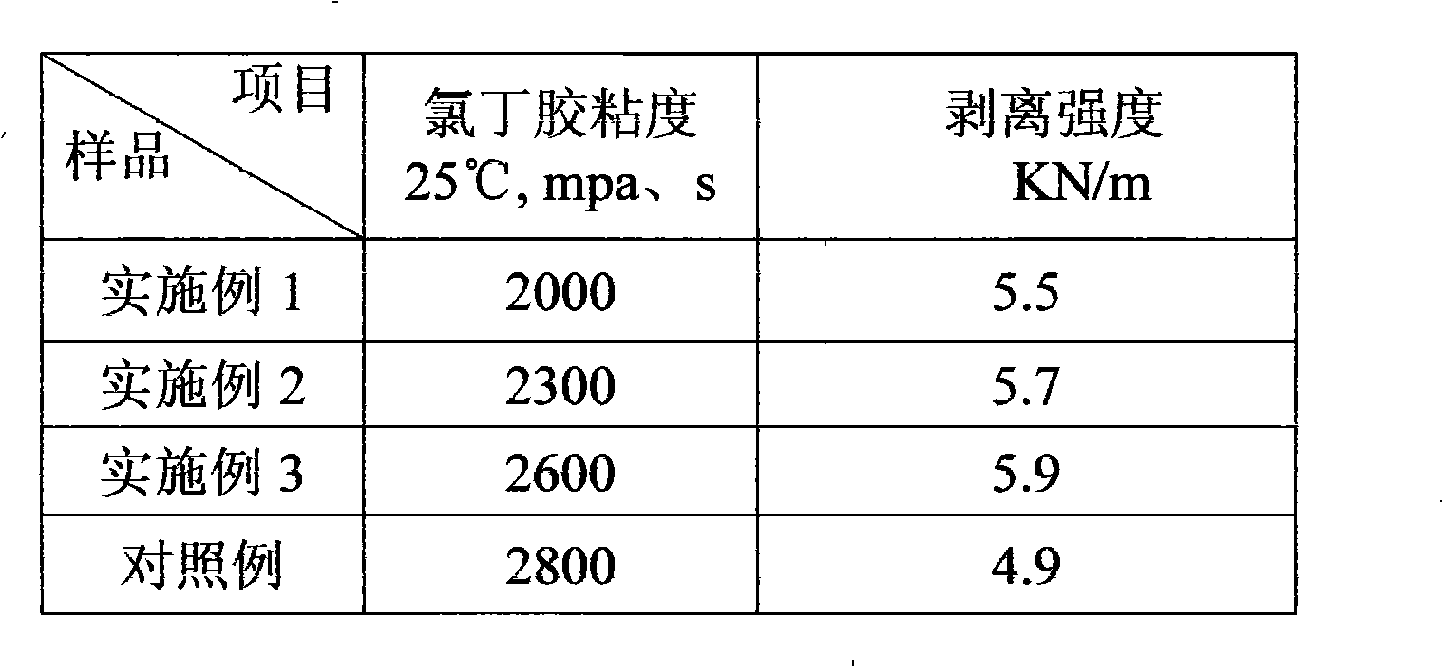

Examples

Embodiment 1

[0014] First, 20 parts of toluene, 25 parts of ethyl ester, 25 parts of cycloethane, and 12 parts of 120# gasoline were pumped into the double-machine dissolving tank in sequence, the temperature was raised to 30°C, and the mixer was started at a speed of 60 rpm. Then, put 14 parts of neoprene film, 4 parts of phenolic resin, 0.4 part of light magnesium oxide, 0.03 part of catalyst triethanolamine, and 2640.2 parts of additives from the manhole of the dual-machine dissolution kettle. Turn on the high-speed shear disperser in the dissolution kettle, adjust the rotating speed to 1400 rpm, and high-speed shear dissolves neoprene film, phenolic resin, light magnesium oxide and other materials. The temperature of the material in the dissolution kettle is controlled to be 40° C. by heating or cooling the water in the jacket of the dissolution kettle, and the product of the present invention is obtained by filtering and discharging after 8 hours of dispersion operation.

Embodiment 2

[0016] Pump 22 parts of toluene, 25 parts of ethyl ester, 20 parts of cycloethane, and 12 parts of 120# gasoline into the double-machine dissolving tank in sequence, raise the temperature to 40°C, and start the mixer at a speed of 80 rpm. Then drop 15 parts of neoprene film, 4 parts of phenolic resin, 0.4 part of light magnesium oxide, 0.03 part of catalyst triethanolamine, and 0.15 parts of auxiliary agent 246 from the manhole of the double-machine dissolution kettle. Speed up to 1100 rpm, use the water in the jacket of the dissolution kettle to heat or cool the temperature of the material in the dissolution kettle to control the temperature of 45 ° C, disperse and run for 5 hours and then filter out the material to obtain the product of the present invention.

Embodiment 3

[0018] Pump 24 parts of toluene, 25 parts of ethyl ester, 20 parts of cycloethane, and 10 parts of 120# gasoline into the dual-machine dissolving kettle in sequence, raise the temperature to 50°C, start the mixer at a speed of 100 rpm, and then dissolve the Put into the manhole of the kettle, 16 parts of neoprene film, 5 parts of phenolic resin, 0.5 part of light magnesium oxide, 0.04 part of catalyst triethanolamine, 0.25 part of auxiliary agent 264, open the high-speed shear disperser in the dissolution kettle and adjust the speed to 1250 RPM, use the water in the jacket of the dissolution kettle to heat or cool to control the temperature of the material in the dissolution kettle to 50°C, disperse and run for 6.5 hours and then filter out the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com