Organic thin-film transistor and manufacture method thereof

A technology of organic thin film and transistor, which is applied in the field of organic thin film transistor and its preparation, can solve the disadvantages of large-scale production of organic thin film transistor, etc., and achieve the effects of easy tailoring and processing, improved performance and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

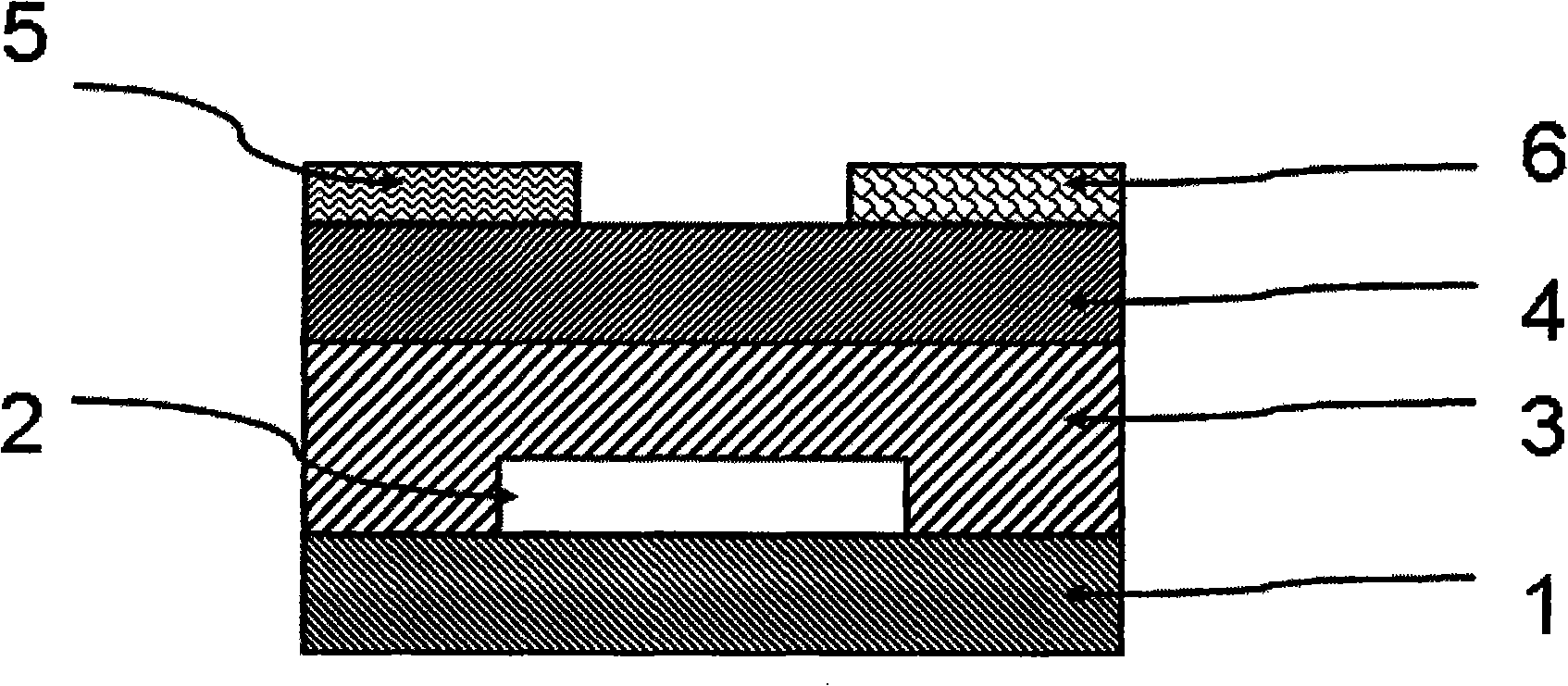

[0046] Such as figure 1 In the structure shown, substrate 1 is made of Si substrate, gate electrode 2 is made of DC magnetron sputtered ITO transparent conductive film, ultraviolet curing adhesive is used as organic gate insulating layer 3, source electrode 5 is made of Cr metal film as electrode layer, and leakage current Electrode 6 also uses Cr metal thin film as an electrode layer, and organic semiconductor layer 4 uses pentacene pentance.

[0047] The preparation method is as follows:

[0048] ① Thoroughly clean the Si substrate first, and blow dry with dry nitrogen after cleaning;

[0049] ② Evaporate the gate electrode on the surface of the Si substrate by DC magnetron sputtering;

[0050] ③Etching the ITO gate electrode pattern by photolithography;

[0051] ④ On the Si substrate plated with the gate electrode, spin-coat the UV-curable adhesive organic gate insulating layer by spin-coating;

[0052] ⑤ Carrying out ultraviolet curing and heating and baking the formed...

Embodiment 2

[0057] Such as figure 1 In the structure shown, substrate 1 is made of Si substrate, gate electrode 2 is made of DC magnetron sputtered ITO transparent conductive film, ultraviolet curing adhesive is used as organic gate insulating layer 3, source electrode 5 is made of Cr metal film as electrode layer, and leakage current The electrode 6 also adopts Cr metal thin film as an electrode layer, and the organic semiconductor layer 4 adopts CuPc.

[0058] The fabrication process of the device is similar to that of Example 1.

Embodiment 3

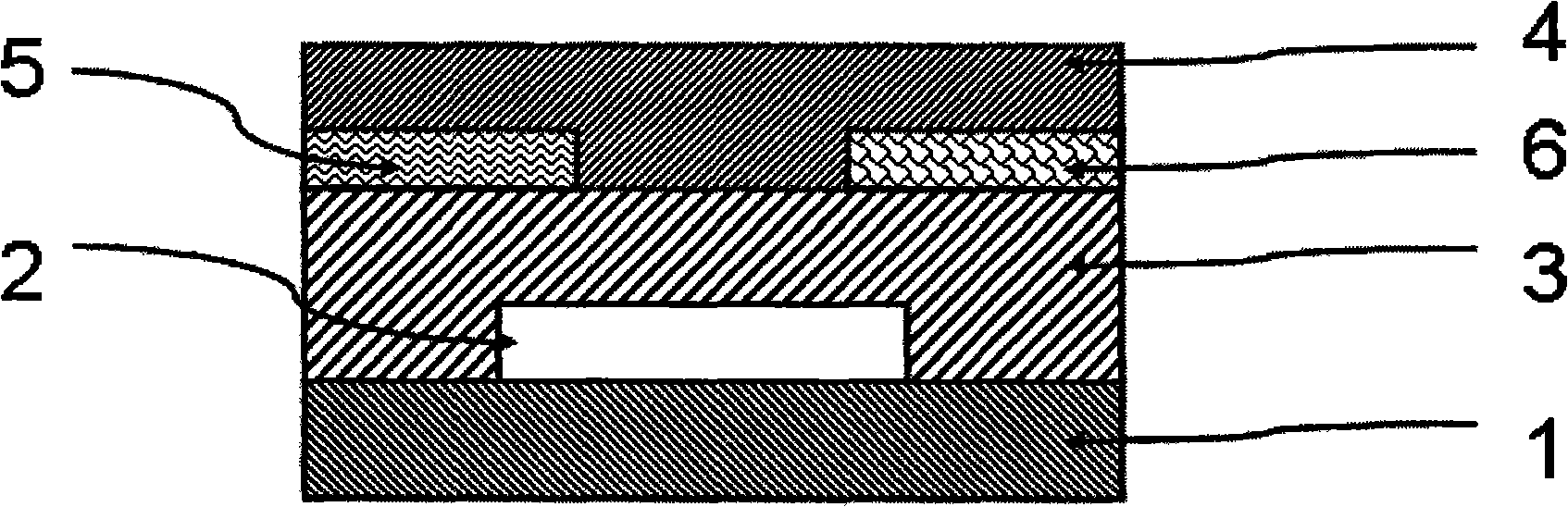

[0060] Such as figure 2 In the structure shown, substrate 1 is made of Si substrate, gate electrode 2 is made of DC magnetron sputtered ITO transparent conductive film, ultraviolet curing adhesive is used as organic gate insulating layer 3, source electrode 5 is made of Cr metal film as electrode layer, and leakage current The electrode 6 also uses Cr metal thin film as the electrode layer, and the organic semiconductor layer 4 uses pentacene.

[0061] The preparation method is as follows:

[0062] ① Thoroughly clean the Si substrate first, and blow dry with dry nitrogen after cleaning;

[0063] ② Evaporate the gate electrode on the surface of the Si substrate by DC magnetron sputtering;

[0064] ③Etching the ITO gate electrode pattern by photolithography;

[0065] ④ On the Si substrate plated with the gate electrode, spin-coat the UV-curable adhesive organic gate insulating layer by spin-coating;

[0066] ⑤ Carrying out ultraviolet curing and heating and baking the forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com