Hard-surface build-up welding strain roller and manufacture method thereof

A technology of tension roller and hard surface, which is applied in the direction of manufacturing tools, rollers, metal rolling, etc. It can solve the problem that heat easily enters the roller from the joint between the roller and the cover, is pressed into pits or protrusions, and affects the belt. Steel surface quality and other issues to achieve the effect of ensuring excellent performance, energy density, and high bonding strength of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

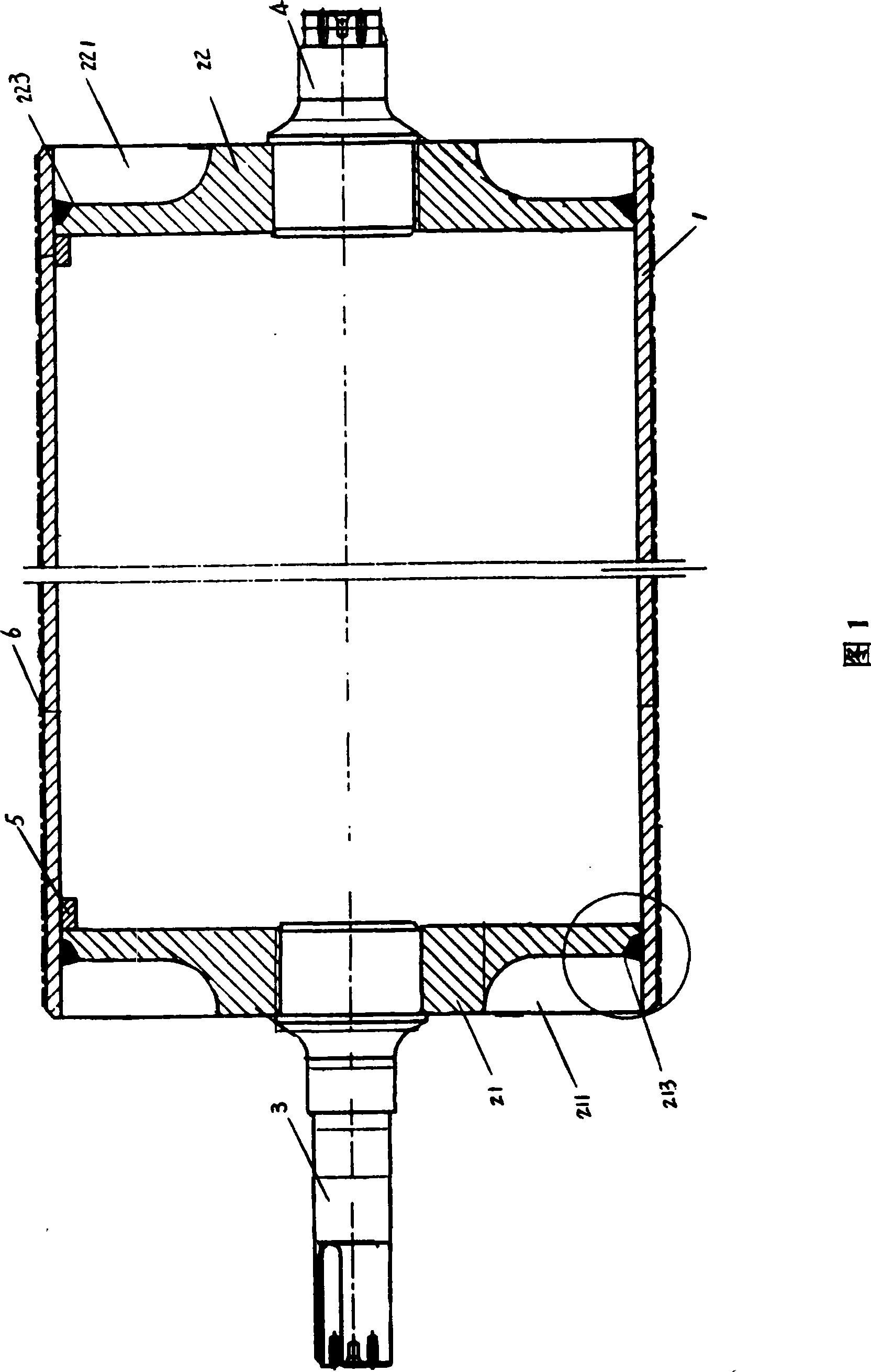

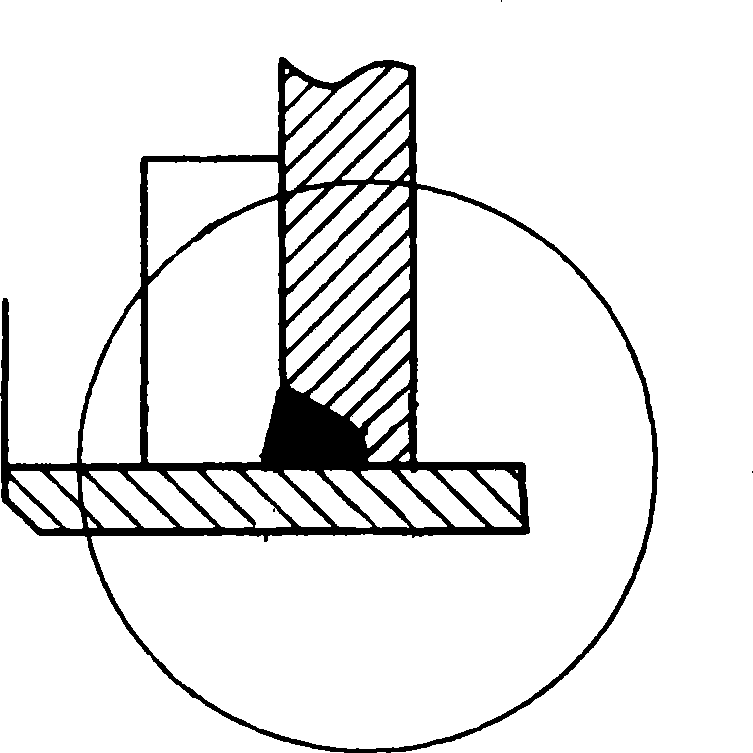

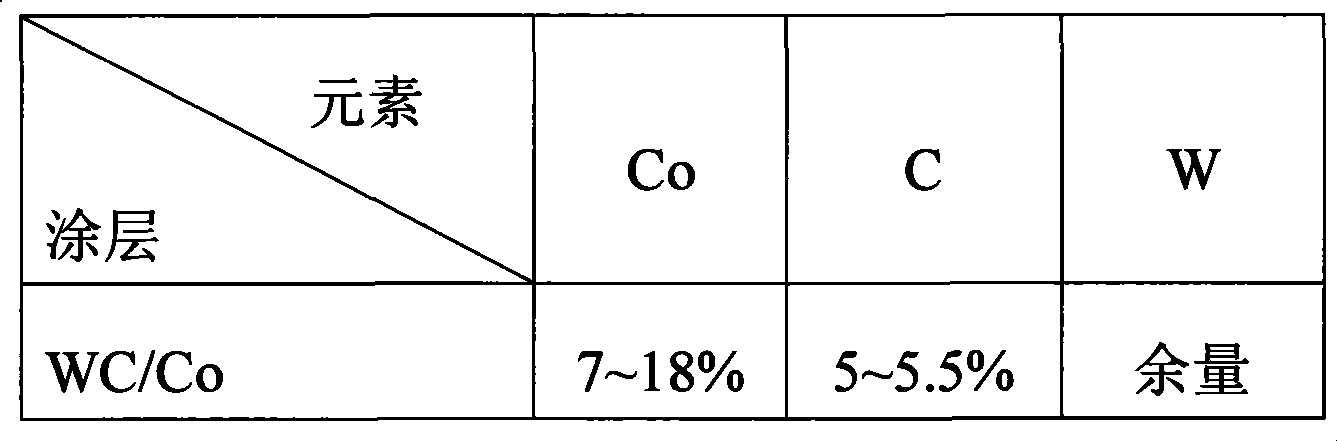

[0033] Please refer to Fig. 1, 2, the present invention discloses a kind of hard surface welding tension roller. It includes a roller 1 and circular side covers 21 and 22 fixedly covering the openings at both ends of the roller 1. The two ends of the roller 1 are respectively provided with square steel 5, and the two side covers 21 and 22 are erected on the square steel 5. superior. The centers of the circles of the two side covers 21 and 22 are pivotally connected with the left shaft head 3 and the right shaft head 4 respectively. The outer surface of the roller 1 is covered with a spray coating 6, and the outer rings of the two side covers 21, 22 are provided with grooves 211, 221, and the grooves 211, 221 extend from the middle of the side covers 21, 22 to the edge, and the two side covers 21 , 22 The outer ring is provided with chamfers 213, 223, and the two side covers 21, 22 are welded to the inner walls at both ends of the roller 1 through the chamfers 213, 223 and gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com