Method for preparing polyolefin/nano calcium carbonate mixture

A nano-calcium carbonate and polyolefin technology is applied in the field of polymer material preparation, which can solve the problems of dust pollution, large equipment investment and high energy consumption, and achieve the effect of avoiding the melting and granulating process and avoiding energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

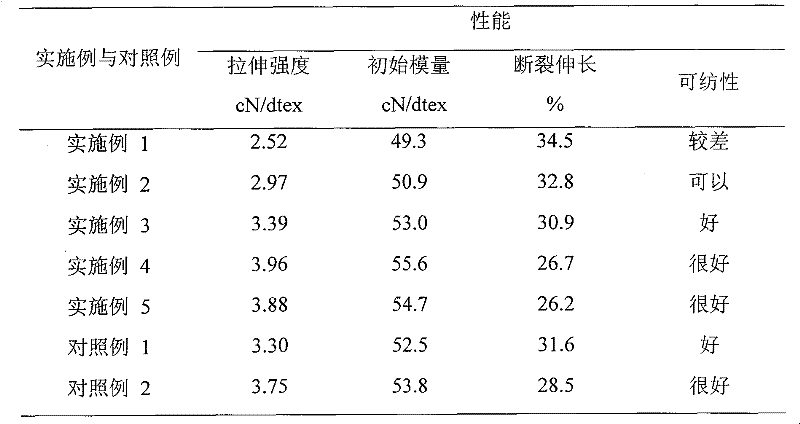

[0021] Add 62 kg of nano-calcium carbonate, 1.5 kg of methacrylic acid, 1.24 kg of aluminate coupling agent, 0.0092 kg of composite antioxidant B225, and 0.28 kg of reactive monomer maleic anhydride to a 200-liter high-speed mixer. Density polyethylene (grafting ratio 1.2 mmol / 100 g) and 46 kg polypropylene (melt index 21 g / 10 min). The speed of high-speed mixing is 3000 rpm, the heating power is 2KW, and the temperature of the system reaches 110°C after 10 minutes. All additives are evenly coated on the polypropylene particles, and the heating and mixing are stopped. The mixture was spun into fibers with a screw spinning machine, and the properties of the fibers are shown in Table 1.

Embodiment 2

[0023] In 200 liters of high-speed mixers, add 45 kilograms of nano-calcium carbonates, 2.2 kilograms of methacrylic acid, 0.9 kilograms of aluminate coupling agents, 0.013 kilograms of composite antioxidant B225, 0.3 kilograms of maleic anhydride grafted linear low-density polyethylene ( Grafting rate 1.2 mmol / 100 g) and 65 kg polypropylene (melt index 21 g / 10 min). The speed of high-speed mixing is 3000 rpm, the heating power is 2KW, and the temperature of the system reaches 110°C after 25 minutes. All additives are evenly coated on the polypropylene particles, and the heating and mixing are stopped. The mixture was spun into fibers with a screw spinning machine, and the properties of the fibers are shown in Table 1.

Embodiment 3

[0025] In 200 liters of high-speed mixers, add 30 kilograms of nano-calcium carbonates, 3.2 kilograms of methacrylic acid, 0.6 kilograms of aluminate coupling agents, 0.017 kilograms of composite antioxidant B225, 0.3 kilograms of maleic anhydride grafted linear low-density polyethylene ( Grafting rate 1.2 mmol / 100 g) and 85 kg polypropylene (melt index 21 g / 10 min). The speed of high-speed mixing is 3000 rpm, the heating power is 2KW, and the temperature of the system reaches 110°C after 10 minutes. All additives are evenly coated on the polypropylene particles, and the heating and mixing are stopped. The mixture was spun into fibers with a screw spinning machine, and the properties of the fibers are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com