Laser apparatus for patterning at light guide plate of back light unit and method for forming patterns using thereof

A technology of a backlight unit and a laser device, applied in the directions of light guides, optical elements, lighting devices, etc., can solve the problems of reduced reproducibility of graphic shapes, large CAD data capacity, consumption, etc., and achieve the effect of rapid composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, the light guide plate patterning laser device for the backlight unit of the present invention and the light guide plate patterning method for the backlight unit using it will be described in detail with reference to the accompanying drawings.

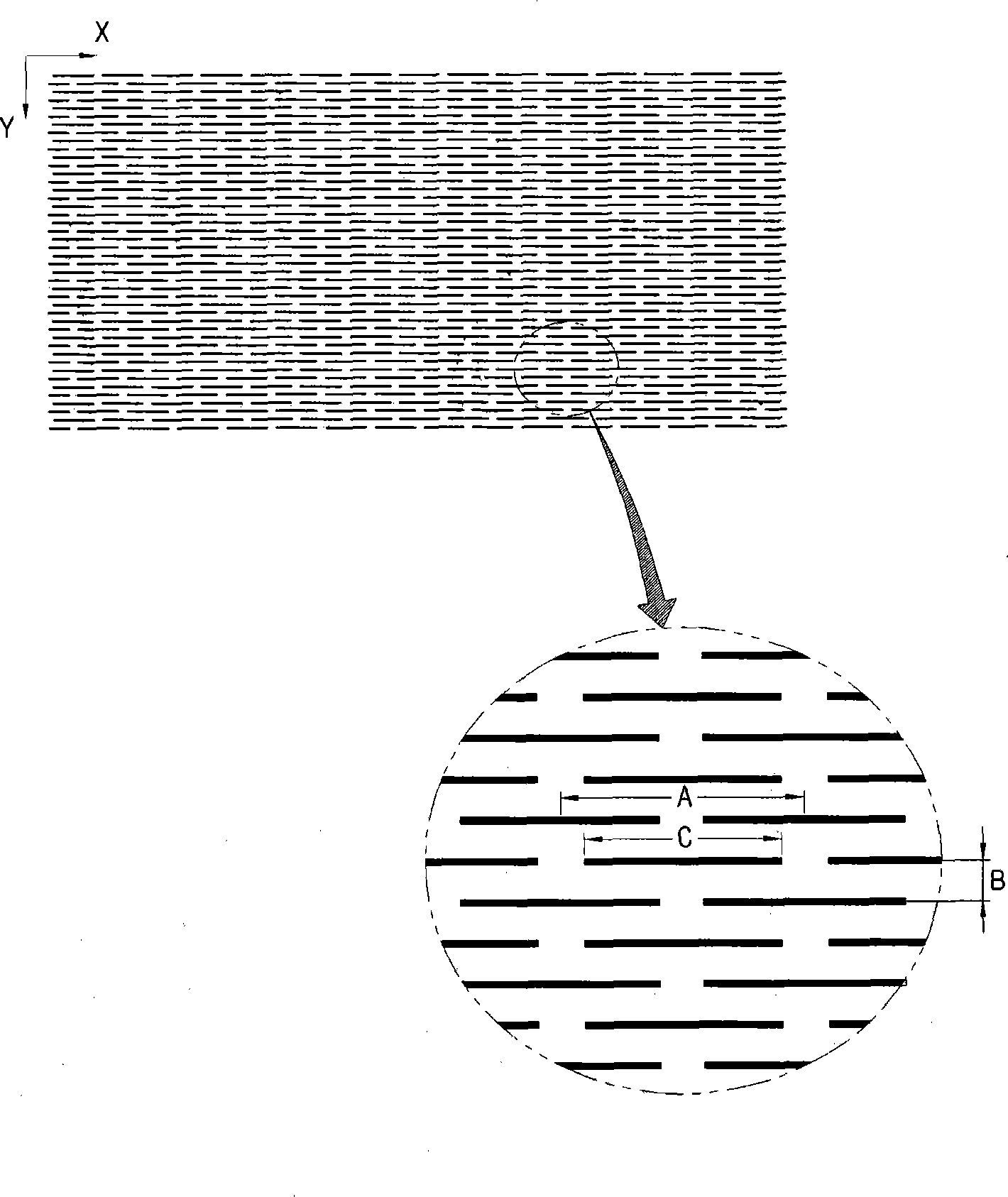

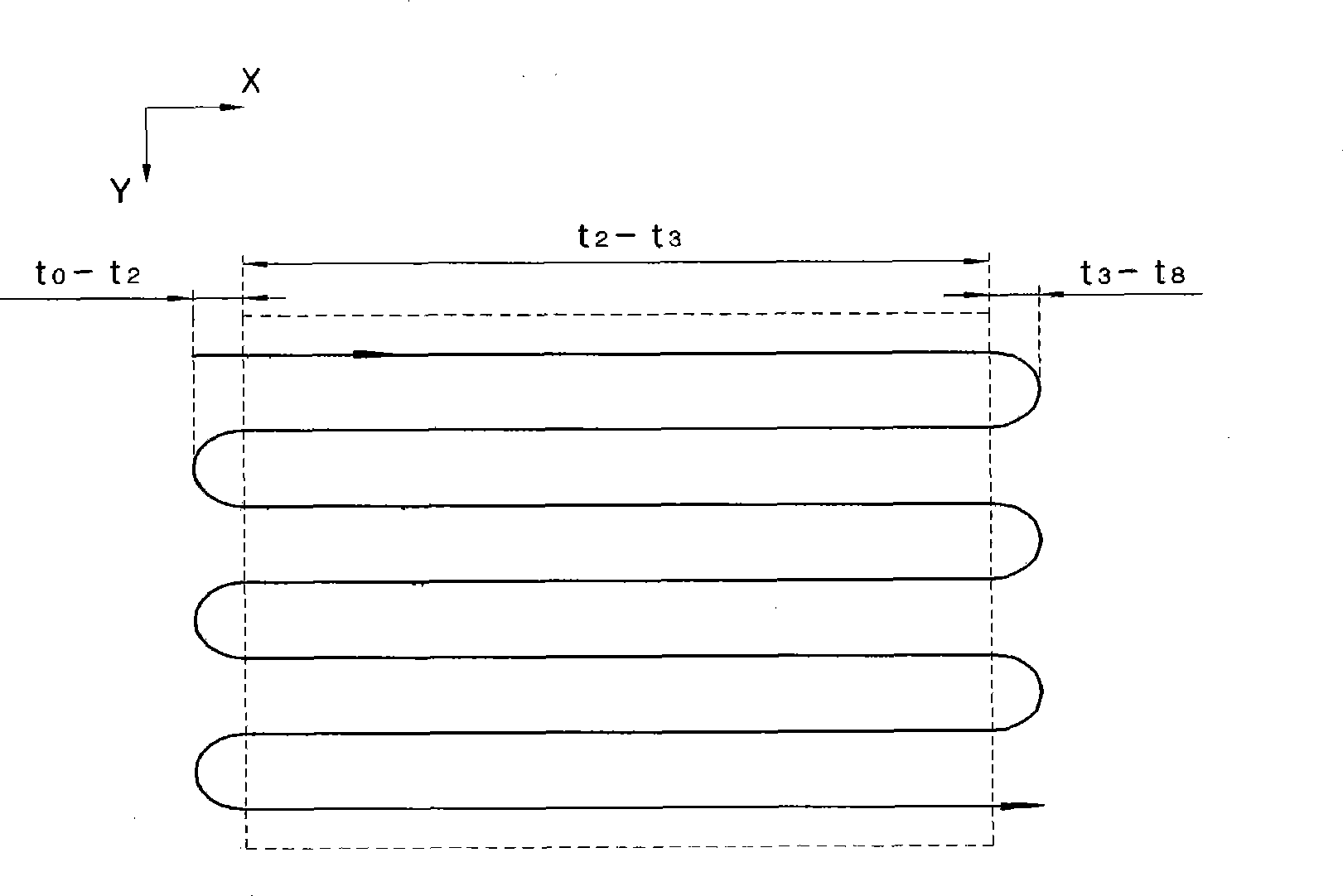

[0060] Figure 4a It is a cross-sectional view of the light guide plate made by the light guide plate patterning method for the backlight unit of the present invention; FIG. 4b is a curve showing the contour line of the pattern depth based on the method.

[0061] Such as Figure 4a As shown, the light guide plate manufactured by the light guide plate patterning method for the backlight unit of the present invention is characterized in that the depth of the formed pattern has a contour line that changes as the Y coordinate increases away from the light source, thereby making the light emitted from the light source The light has the same brightness after being reflected.

[0062] As shown in Figure 4b, the above Figure 4a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com