Device for forming quasi-double half-gauss hollow laser beam

A technology of hollow laser beam, Gaussian, used in the field of laser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

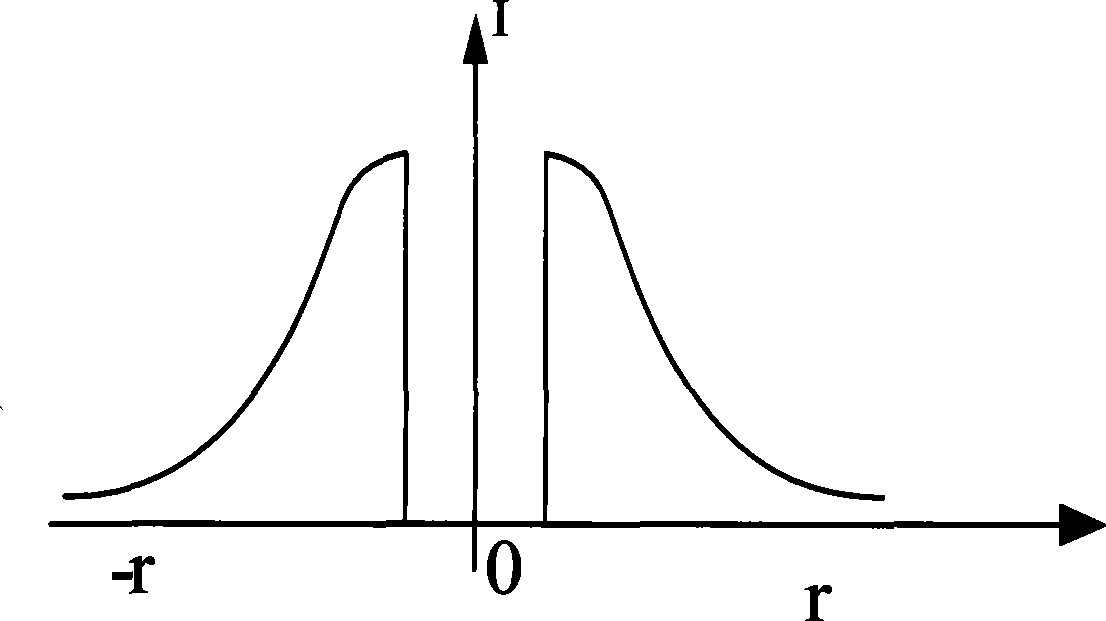

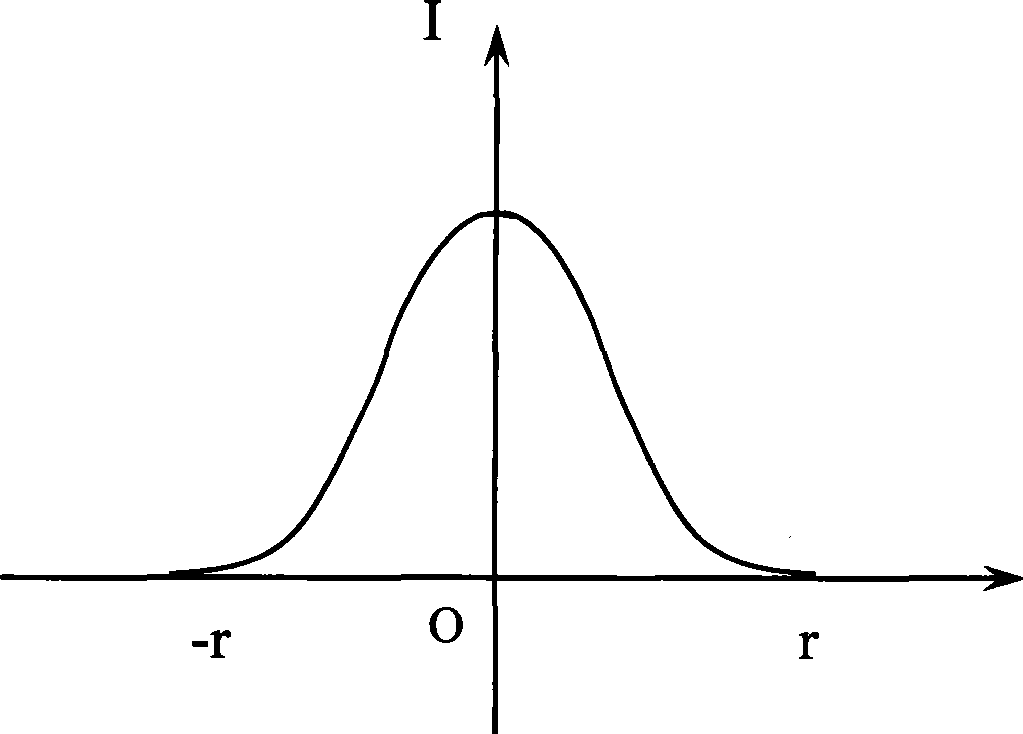

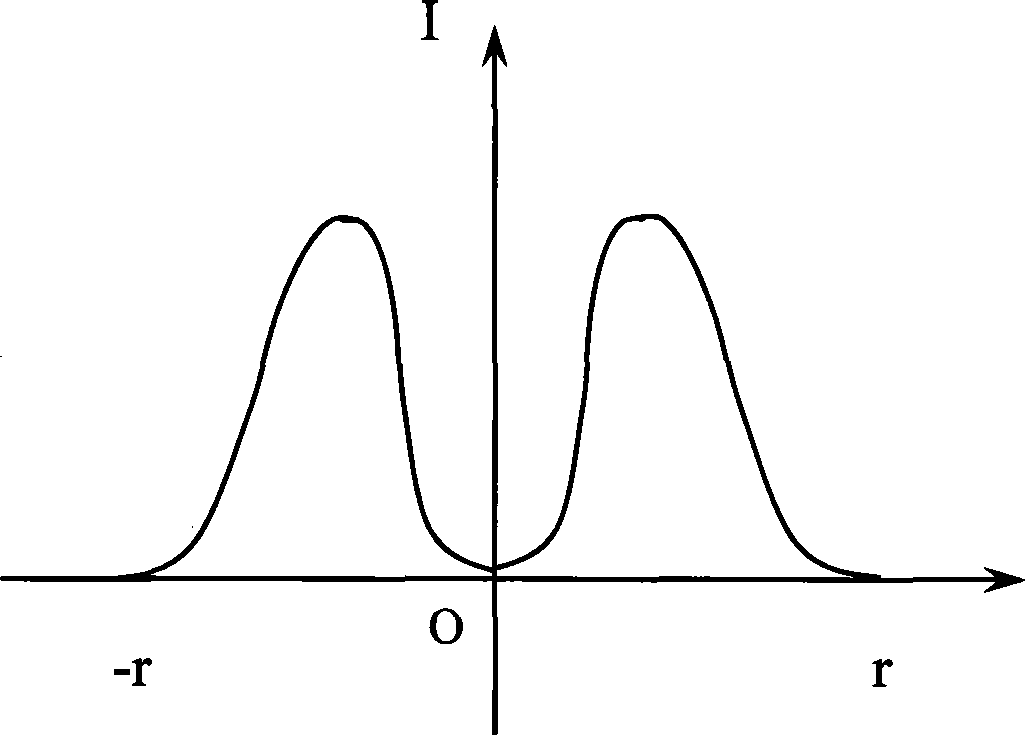

[0010] See Figure 5 , shown in Fig. 6, double semi-Gaussian hollow laser beam forming device is made up of concave spherical reflector 6, positive axis conical reflector 7, positive lens 8 successively, three optical coaxial, the cone of positive axis conical reflector 7 The surface is opposite to the concave spherical surface of the concave spherical reflector 6. The concave spherical reflector 6 and the positive axis conical reflector 7 are made of metal or glass, and the concave spherical surface and the conical surface are optically polished and coated with a metal or dielectric reflective film. The concave spherical reflector 6 and the positive axis conical reflector 7 belong to optical reflectors. The center of the concave spherical mirror 6 is provided with an incident hole 9 whose aperture is greater than or equal to the diameter of the incident solid Gaussian laser beam. The bottom surface of the positive axis conical reflector 7 is bonded to one side of the plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com