Dry transformer for ozone generator

A technology of dry-type transformers and ozone generators, applied in the field of transformers, can solve problems such as poor heat dissipation, insulation degradation, and increased copper in transformers, and achieve good heat dissipation and ventilation, large contact area, and reduced contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

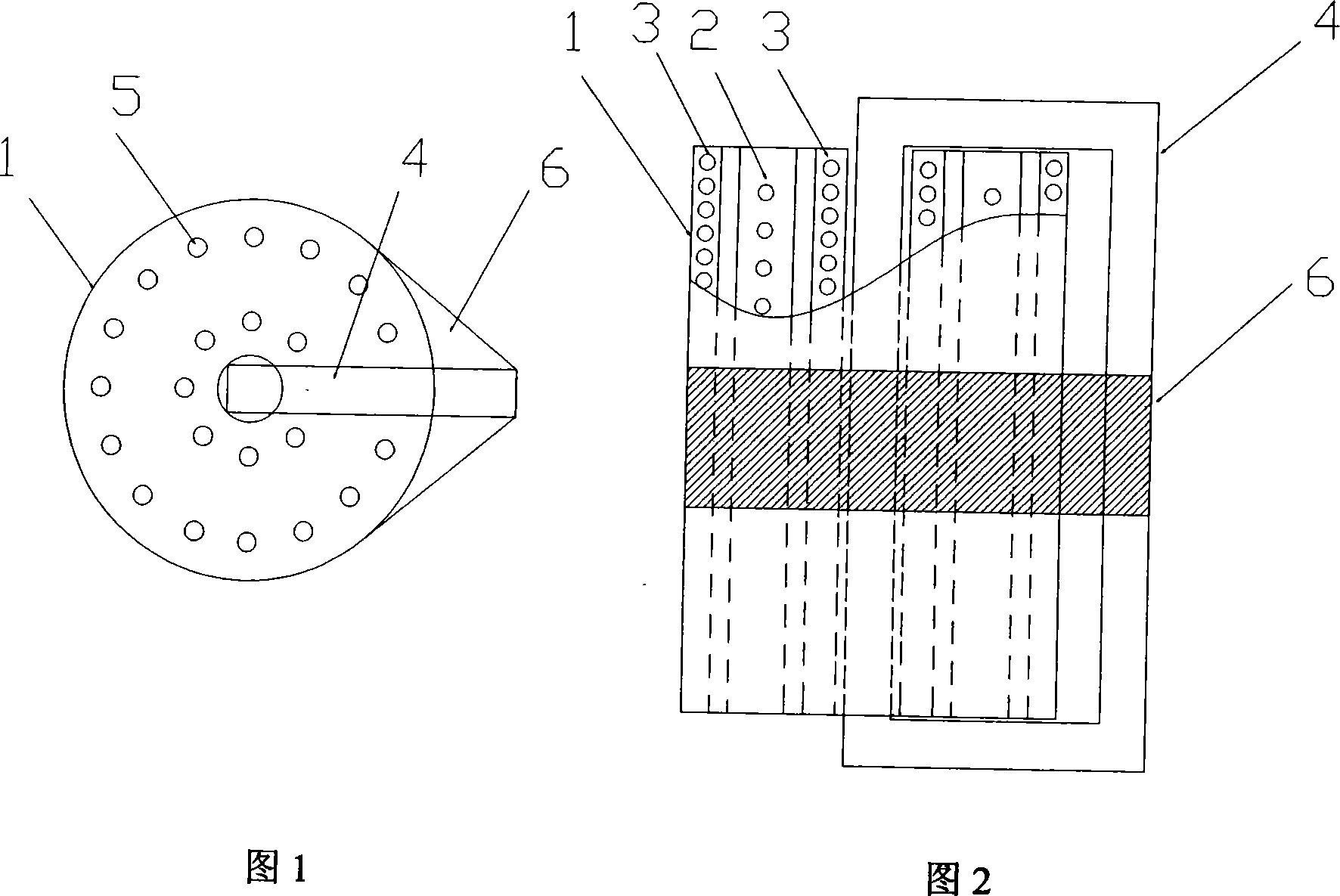

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] In Fig. 1 and Fig. 2, the high and low voltage coils 2 and 3 are arranged in the shell 1, and the high and low voltage coils 2 and 3 are wound between them, and the insulating cylinder 4 is arranged between the high and low voltage coils 2 and 3, and the insulating cylinder 4 is provided with an axial ventilation hole 5, and the low-voltage coil 3 is multi-coiled and wound in layers, and both the turn insulation and the interlayer insulation are potted with epoxy resin. The high-voltage coil 2 is cake-shaped, and comb-shaped stays are used between the wire cakes, which reduces the maximum voltage between the cakes by half and greatly improves the axial short-circuit resistance of the high-voltage coil 2 . The high and low voltage coils 2 and 3 are wrapped around, which enhances the mechanical strength and reduces the leakage inductance. The insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com