Hydraulic cake braising machine for peach slice

A hydraulic, peach slice technology, applied in the direction of dough extruder, etc., can solve the problems affecting the quality of peach slices, fresh peach slices, uneven pressing of stewed cakes, low production efficiency, etc., and achieves high production efficiency, uniform pressing, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below by embodiment, the present invention will be further described.

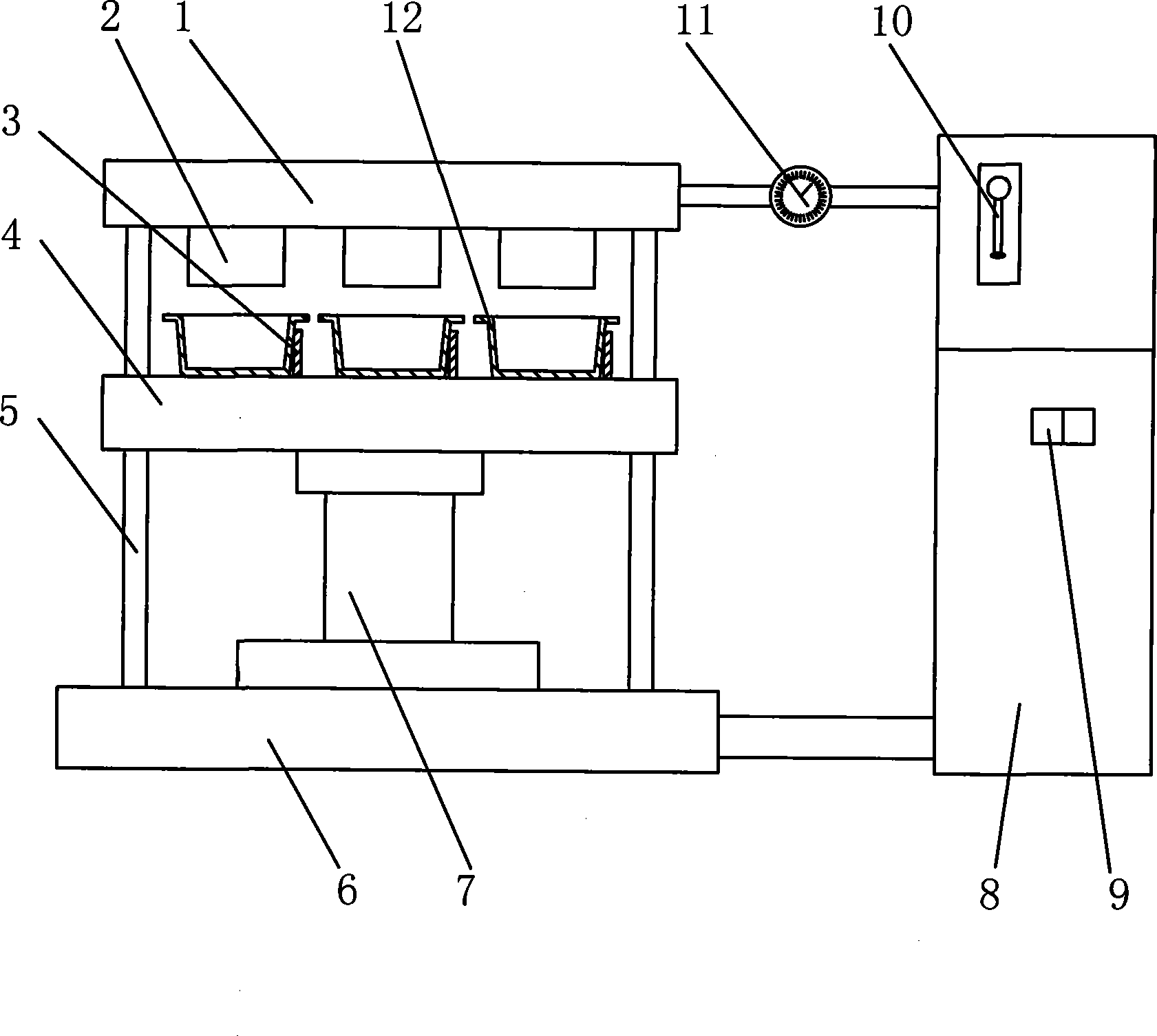

[0014] As shown in the accompanying drawings, a peach slice hydraulic cake stewing machine includes a fixed platen 1, a lifting platform 4, a hydraulic column 5, a base 6, a hydraulic piston 7, a hydraulic box 8, a power switch 9, and an operating rod 10, and is characterized in that : the upper surface of the lifting platform 4 is provided with a positioning block 3, the lower surface of the fixed platen 1 is provided with a module 2, and a cake box 12 is positioned beside the positioning block 3 on the lifting platform 4, and the size of the module 2 is the same as that of the cake The inner space of the box 12 is adapted, and a hydraulic gauge 11 is provided beside the operating rod 10 . The base 6 is a cuboid, the four corners of the base 6 are provided with a hydraulic column 5, the middle part of the base 6 is provided with a cylinder liner, the cylinder liner is provided with a hydraulic pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com