Protein feed optimized by compound micro-organism solid-state aerobic fermentation and preparation method thereof

A technology of protein feed and aerobic fermentation, applied in biochemical equipment and methods, animal feed, animal feed, etc., can solve the problems of lack, restriction of microbial application, low enzyme production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Embodiment 1, the protein feed optimized by compound bacteria solid-state aerobic fermentation

[0085] The protein feed optimized by the solid-state aerobic fermentation of compound bacteria, the weight ratio of each raw material is: 1000 kg of mixed fermentation raw materials, 800 grams of compound bacteria;

[0086] The composition and weight ratio of the mixed fermentation raw materials are: 4 parts of cottonseed meal, 5 parts of rapeseed meal, 2 parts of fresh distiller's grains; the moisture content of the fresh distiller's grains is 58-60%;

[0087] The weight ratio of each raw material in the composite strain is: 4 parts of Aspergillus niger (CICC2139AS3.324), 4 parts of Aspergillus oryzae (CICC2329 Huyao 3.042), and 2 parts of Bacillus subtilis (BNCC188080);

[0088] The number of living bacteria of each raw material in the composite fermentation agent: Aspergillus niger (CICC2139 AS3.324) 1.10×10 10 ~1.15×10 10 cfu / g, Aspergillus oryzae (CICC2329 Shanghai Br...

Embodiment 2

[0090] Embodiment 2, the protein feed optimized by compound bacteria solid-state aerobic fermentation

[0091] The protein feed optimized by compound bacteria solid-state aerobic fermentation, the weight ratio of each raw material is: 1200 kg of mixed fermentation raw materials, 800 grams of compound bacteria;

[0092] The composition and weight ratio of the mixed fermentation raw materials are: 5 parts of cottonseed meal, 4 parts of rapeseed meal, 2 parts of fresh distiller's grains; the moisture content of the fresh distiller's grains is 58-60%;

[0093] The weight ratio of each raw material in the composite strain is: 5 parts of Aspergillus niger (CICC2139AS3.324), 4 parts of Aspergillus oryzae (CICC2329 Huyao 3.042), and 1 part of Bacillus subtilis (BNCC188080);

[0094] The number of living bacteria of each raw material in the composite fermentation agent: Aspergillus niger (CICC2139 AS3.324) 1.10×10 10 ~1.15×10 10 cfu / g, Aspergillus oryzae (CICC2329 Shanghai Brewed 3.0...

Embodiment 3

[0096] Embodiment 3, the preparation method of the protein feed optimized by composite bacteria solid-state aerobic fermentation

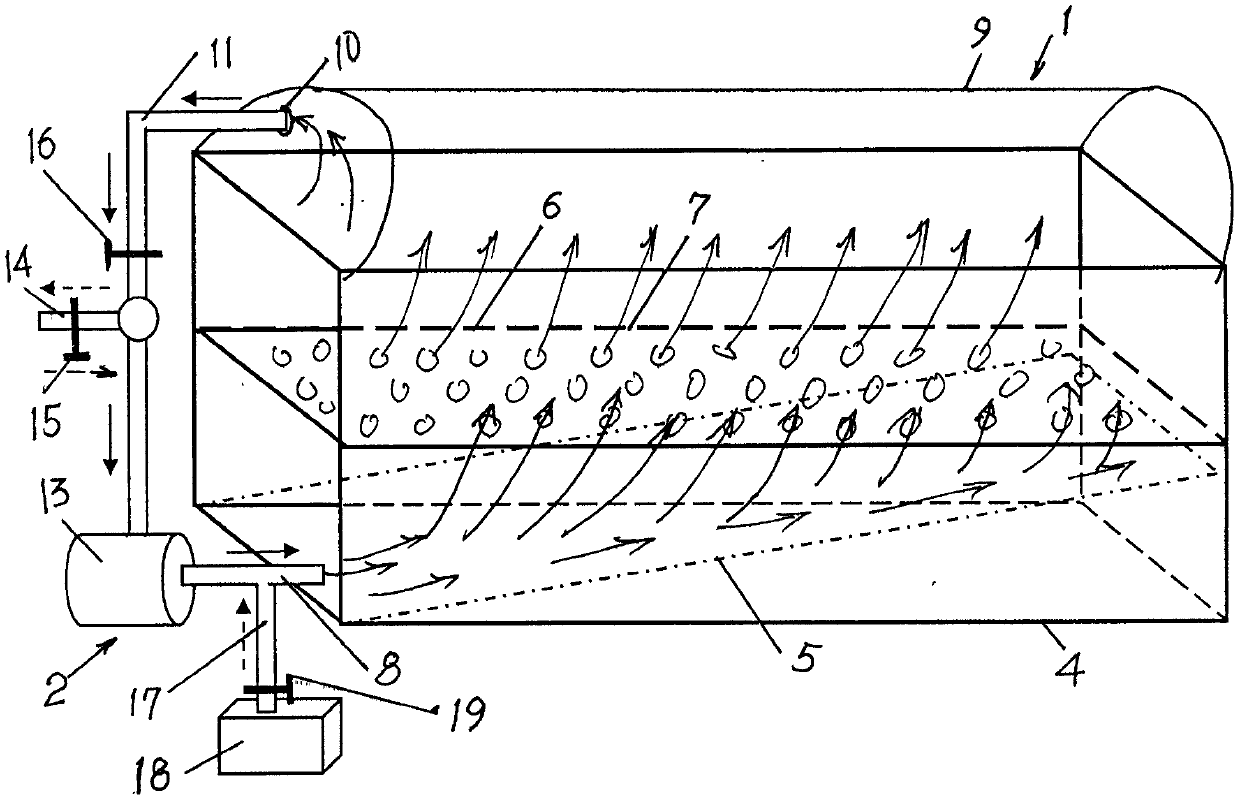

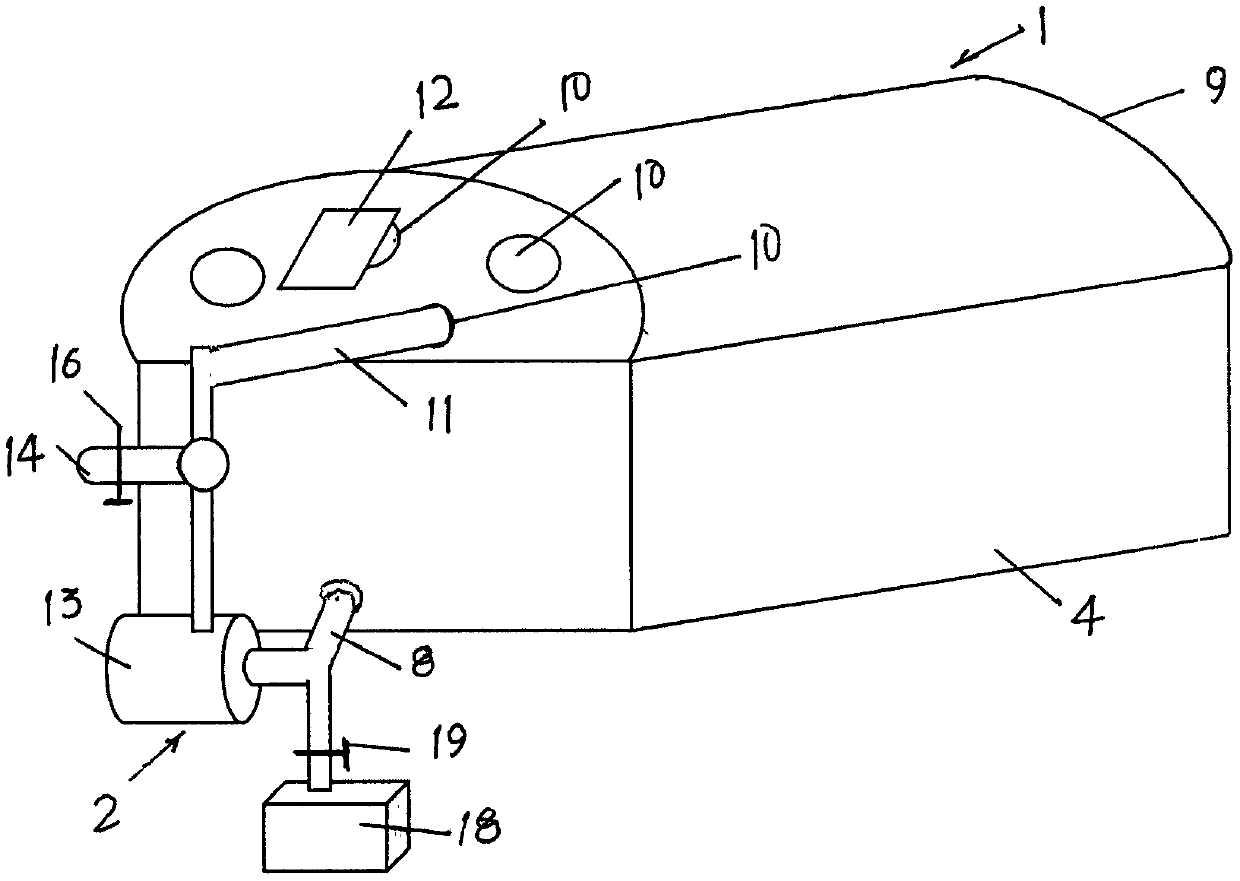

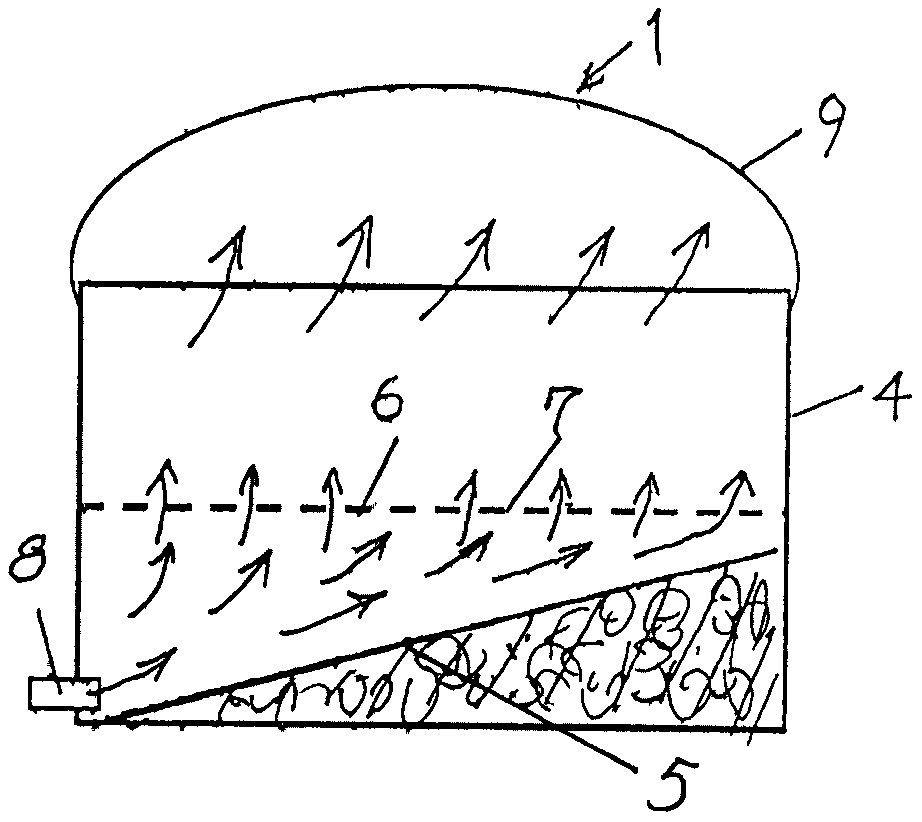

[0097] Such as figure 1 , 2 , 3, 4,

[0098] The preparation method of the protein feed optimized by the solid-state aerobic fermentation of the compound bacteria firstly prepares a special feed fermentation bed with a uniform upper and lower temperature, and then uses the compound bacteria to carry out the solid-state aerobic fermentation of the protein feed to obtain the protein optimized by the solid-state aerobic fermentation of the compound bacteria feed;

[0099] [1] The structure of the dedicated feed fermentation bed with uniform upper and lower temperature includes a canopy fermentation tank 1 and an air-water circulation system 2;

[0100] The structure of the canopy fermenter 1: comprises a long trough container 4 with an upper opening, the bottom of the long trough container 4 is an inclined inclined plane tank bottom 5, between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com