Double-cooling section cooling water blowing apparatus for special-shaped blank continuous casting and uses method

A technology of continuous casting and application method of special-shaped billet, which is applied in the field of metallurgical industrial equipment, can solve problems such as uneven cooling of casting billet, and achieve the effects of low cost, uniform temperature distribution, and simple and easy-to-use application method

Active Publication Date: 2010-11-10

MAANSHAN IRON & STEEL CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The first problem to be solved by the present invention is to provide a cooling water blowing device for the secondary cooling section of the continuous casting of special-shaped billets, the purpose of which is to solve the problem of uneven cooling of the billets caused by the accumulation of water on the inner arc side of the special-shaped billets, and to avoid the uneven cooling of the special-shaped billets. generation of surface and internal defects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

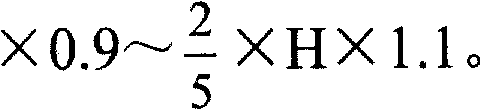

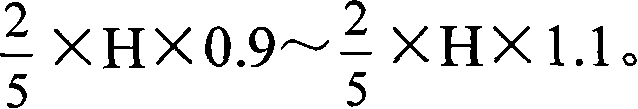

The invention discloses a beam blank continuous casting double cold leg cooling water blowing device. In the device, a gas pipeline(1) is overlapped with a vertical and symmetrical plane(16) of a ventral plate and is parallel to the surface of a beam blank ventral plate(6); and a gas nozzle(2) blows gases towards a beam blank internal arc side ventral plate pressed mark (4) of the beam blank(11).With the technical proposal, the gas nozzle of the water blowing machine blows compressed air or other inert gases towards the water accumulation area of the beam blank ventral plate so as to reduce the accumulated water and to ensure that the accumulated water is evenly distributed over high-temperature parts of the casting blank, so that the surface temperature of the beam blank is more evenly distributed, and the return range of the surface temperature is reduced below 80 DEG C / meter, and the transverse temperature difference on the surface of the ventral plate is reduced below 200 DEG C / meter; the quality of the beam blank is greatly improved, and the incidence rate of the surface crack is reduced below 1 percent; meanwhile, the device and the corresponding application method are simple, easy in operation and are low in cost.

Description

Cooling water blowing device and application method in the secondary cooling section of continuous casting of shaped billets technical field The invention belongs to the technical field of metallurgical industrial equipment, and relates to process equipment for continuous casting of special-shaped billets. More specifically, the invention relates to a cooling water blowing device for the secondary cooling section of continuous casting of special-shaped billets. At the same time, the invention also relates to an application method of the water blowing device. Background technique The continuous casting secondary cooling process has a significant impact on the surface and internal quality of the slab. If the secondary cooling process is unreasonable, the temperature distribution of the slab will be uneven, which will easily lead to various surface and internal defects of the slab. Especially for special-shaped billets, due to their special shape, the cooling water on the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22D11/124

Inventor 孙维汪开忠杜松林吴坚

Owner MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com