Heat pressing novel method for manufacturing wood veneer/laminated veneer lumber

A technology of laminated veneer lumber and a new method, which is applied to the joining of wooden veneers, manufacturing tools, and wood processing appliances, etc. It can improve the economic efficiency of the factory, reduce the thickness of the rotary cutting, and shorten the hot pressing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] Example 1: The length and width are 83.8cm×61.0cm twisted leaf pine five-layer plywood, and the nominal thickness is 15.5mm;

[0016] ●Preparation of veneer: peeling thickness: 3.175mm; average moisture content 3.5%, 5.5%;

[0017] ●Glue type and sizing amount: phenolic resin glue (PF), single-sided sizing amount 157g / m 2 ;

[0018] ●Press: The width is 91cm×91cm single-layer hot press;

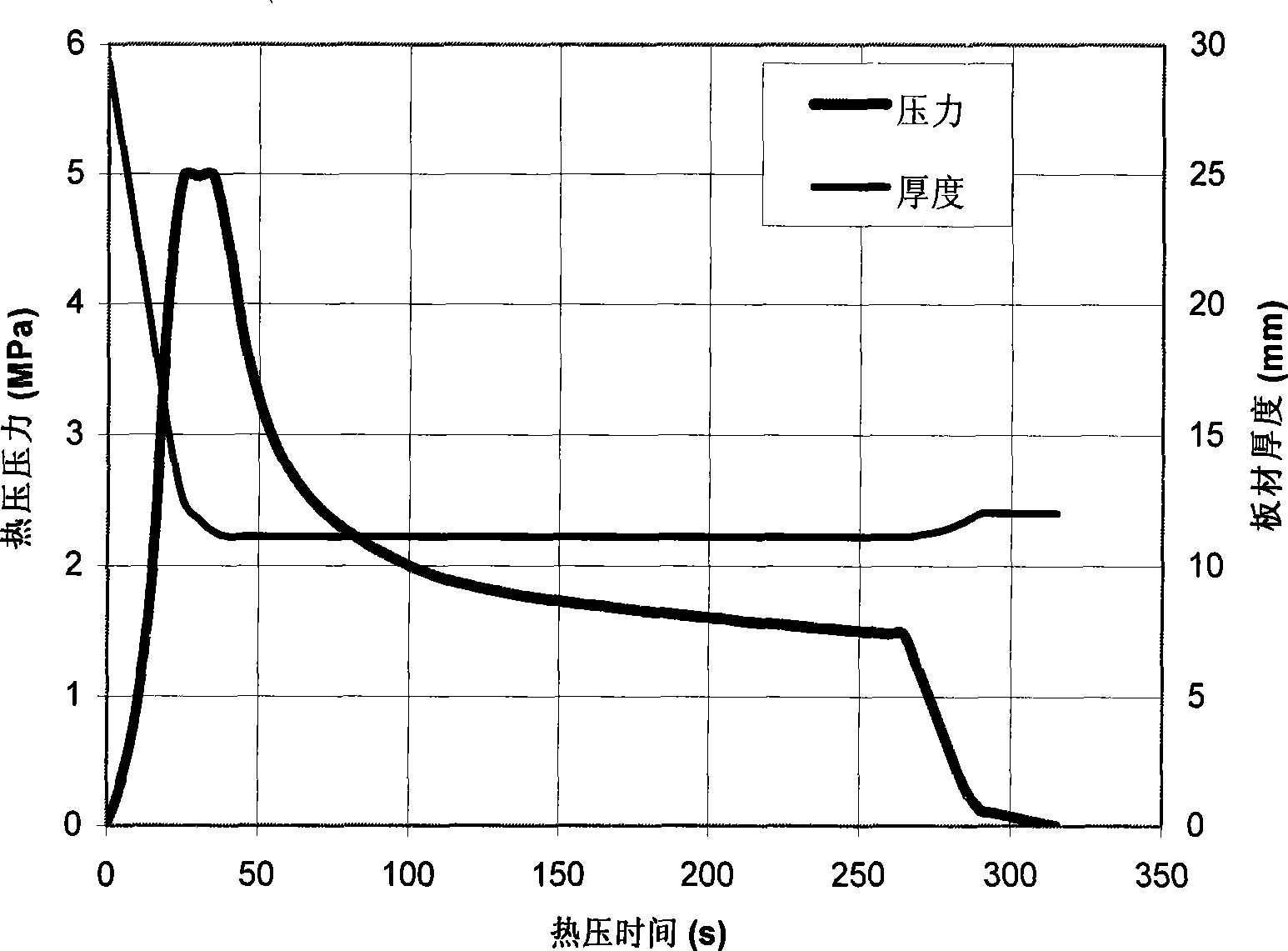

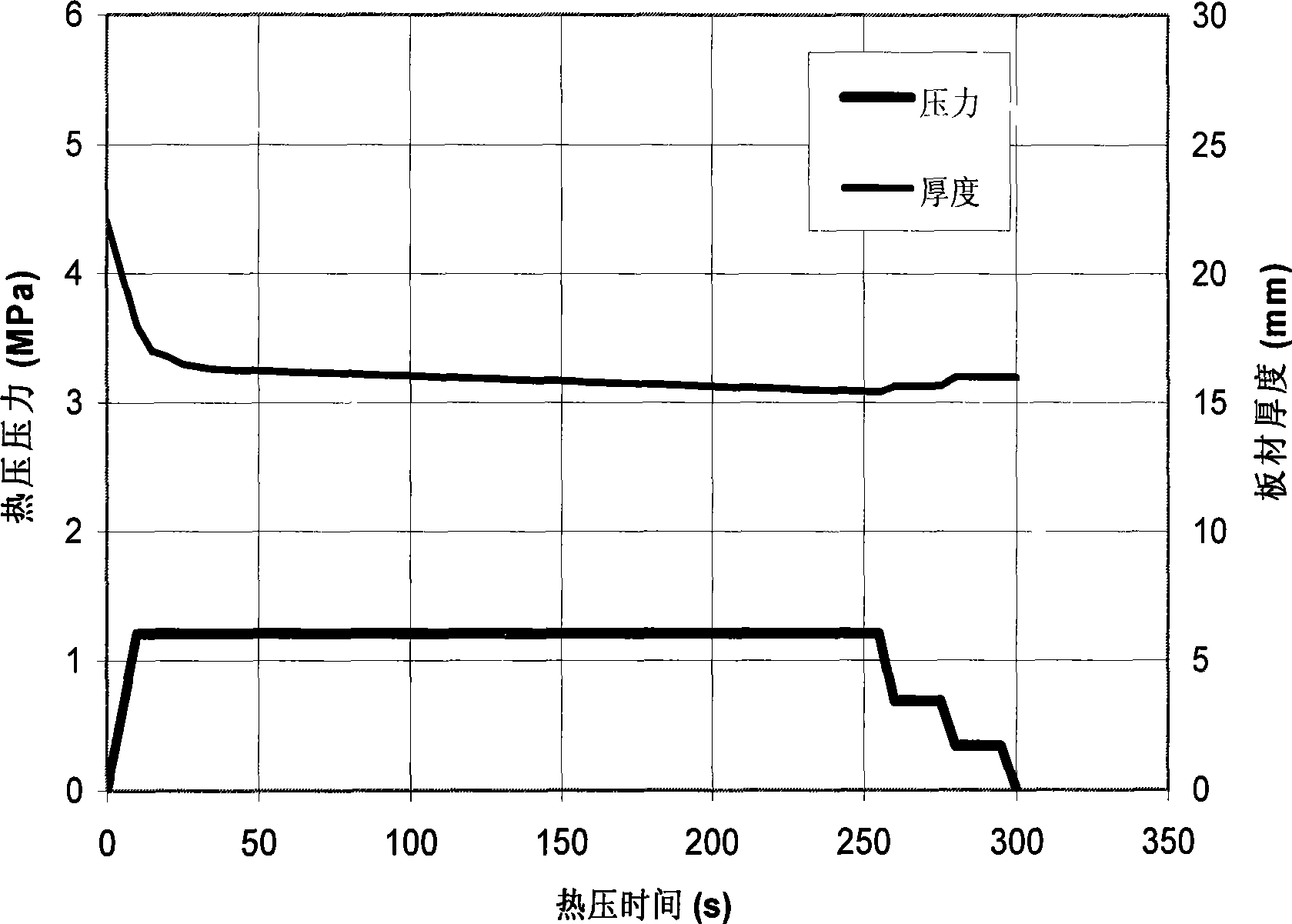

[0019] ◆Conventional process (hot-pressing control curve is similar to attached figure 2 ): hot pressing pressure 1.31MPa; hot pressing temperature 155℃;

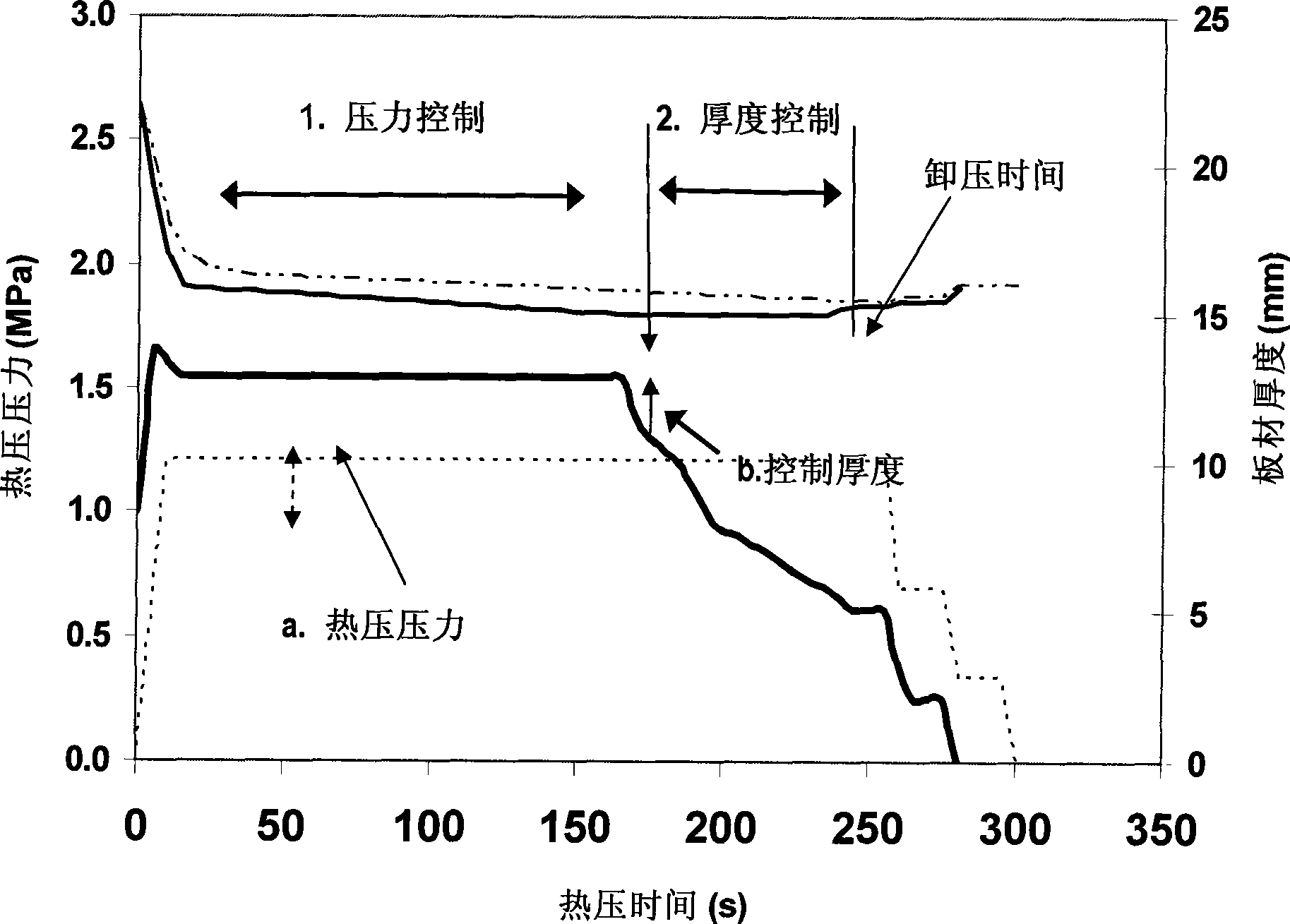

[0020] ◆New process (hot-pressing control curve is similar to attached image 3 shown): the hot-pressing pressure is 0.3-0.8MPa higher than the conventional hot-pressing according to the moisture content of the veneer; the hot-pressing temperature is 155°C;

[0021] For the two processes, when the temperature of the most central adhesive layer in the thickness direction of the sheet is 110 °C, the pressure relief begins, and t...

example 2

[0025] Example 2: The length and width are 83.8cm×61.0cm, thirteen layers of twisted leaf pine veneer laminated timber, the thickness of the board is 37.7 or 38.0mm;

[0026] ●Preparation of veneer: peeling thickness: 3.175mm; average moisture content 3.5%, 5.5%, 9.0%;

[0027] Glue type and sizing amount: phenolic resin glue (PF), single-sided sizing amount 171g / m 2 ;

[0028] ●Press: The width is 91cm×91cm single-layer hot press;

[0029] ◆Conventional process (hot-pressing control curve is similar to attached figure 2 ): hot pressing pressure 1.31MPa; hot pressing temperature 155℃;

[0030] ◆New process (hot-pressing control curve is similar to attached image 3 ): The hot pressing pressure is 0.3-0.8MPa higher than the conventional hot pressing according to the moisture content of the veneer; the hot pressing temperature is 155℃;

[0031] For both processes, the pressure relief starts when the temperature of the most central adhesive layer in the thickness direction ...

example 3

[0035] Example 3: The length and width are 1220mm×2440mm five-layer plywood, and the nominal thickness is 15.5mm;

[0036] ●Veneer preparation: 3.338mm thick Douglas fir veneer; moisture content is 3%;

[0037] ●Glue type and sizing amount: phenolic resin glue (PF), single-sided sizing amount 157g / m 2 ;

[0038] ●Preload: 3 minutes

[0039] ●Press: 40-layer periodic hot press;

[0040] ◆Conventional process (hot-pressing control curve is similar to attached figure 2 ): A total of 40 sheets were pressed, and the process was: hot-pressing pressure 1.31MPa; hot-pressing time 285 seconds; hot-pressing temperature 140.5°C;

[0041] ◆New process (plate compression control unit is installed on the press): a total of 40 sheets are pressed, and the process is: hot pressing pressure 1.45MPa (limited by the hydraulic system of the factory press, the pressure is only 0.14MPa higher than the conventional hot pressing); The constant pressure holding time is 240 seconds; the total hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com