Double-stage braking hydraulic station with high-reliability scavenge oil and control method thereof

A two-level braking and reliability technology, applied in conveyors, hoisting devices, transportation and packaging, etc., can solve the problems of inability to achieve two-level braking, prone to mechanical failures, failures that cannot be found, etc., to achieve wide practicality High performance, compact structure, good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

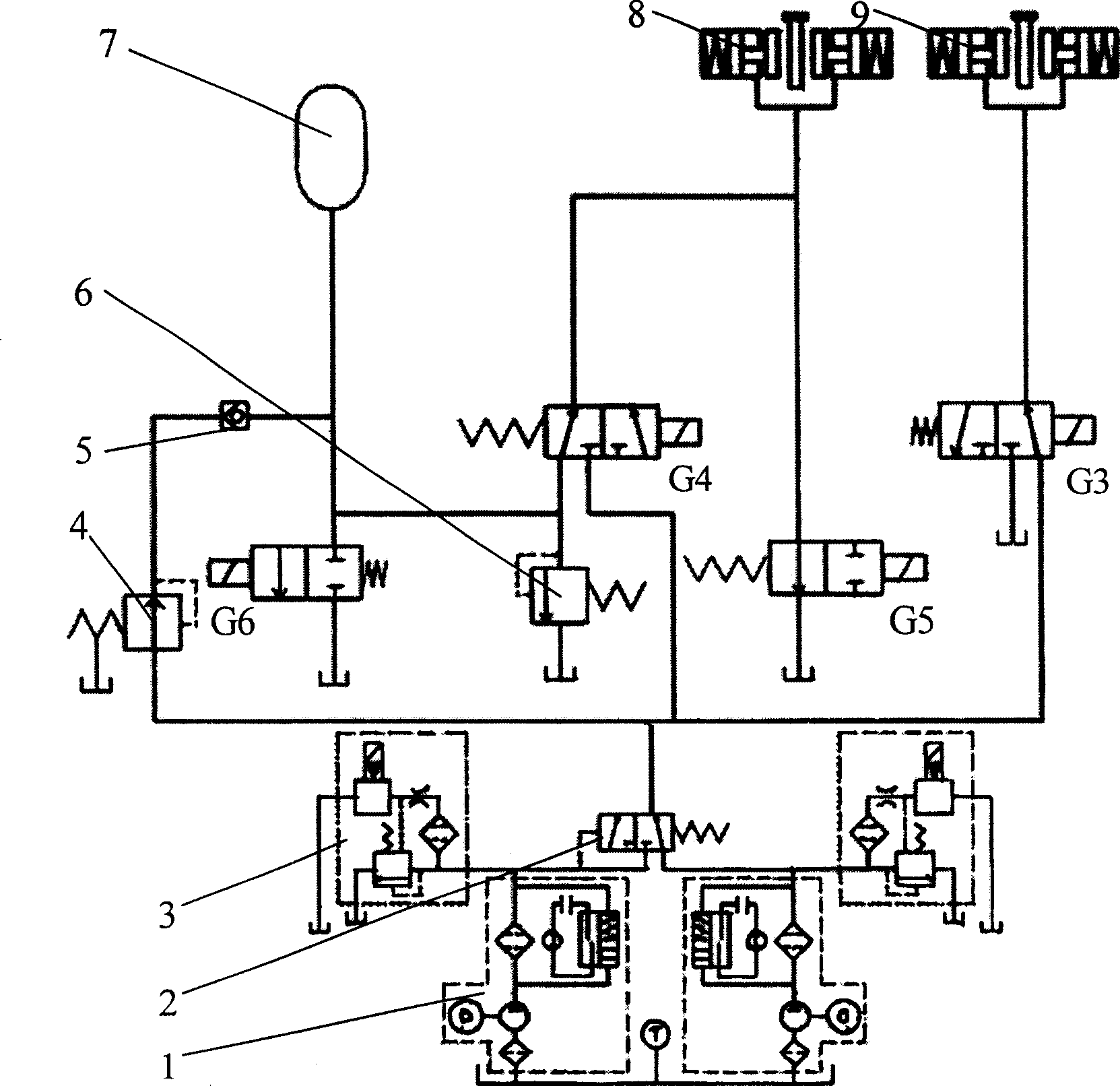

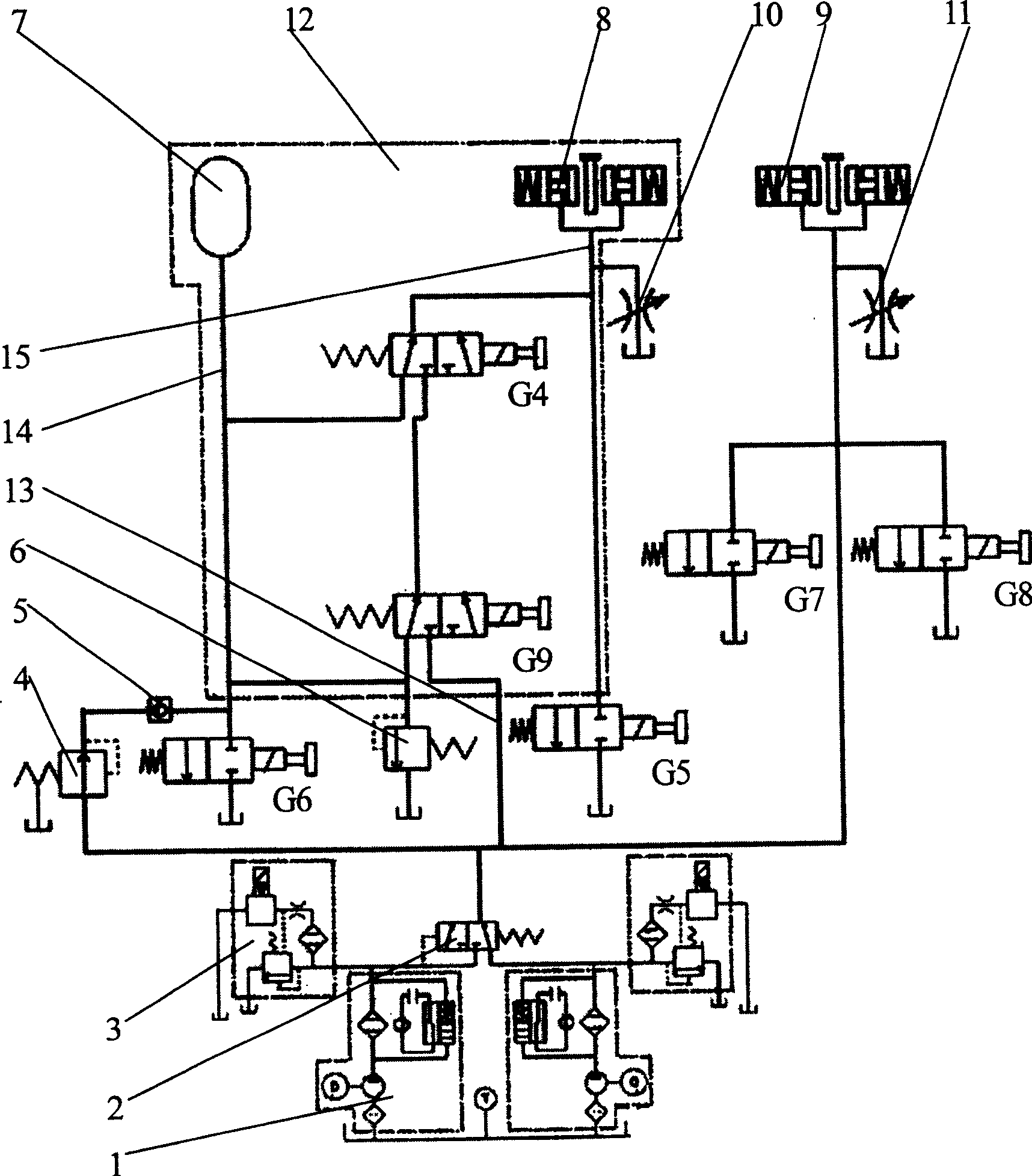

Embodiment 1

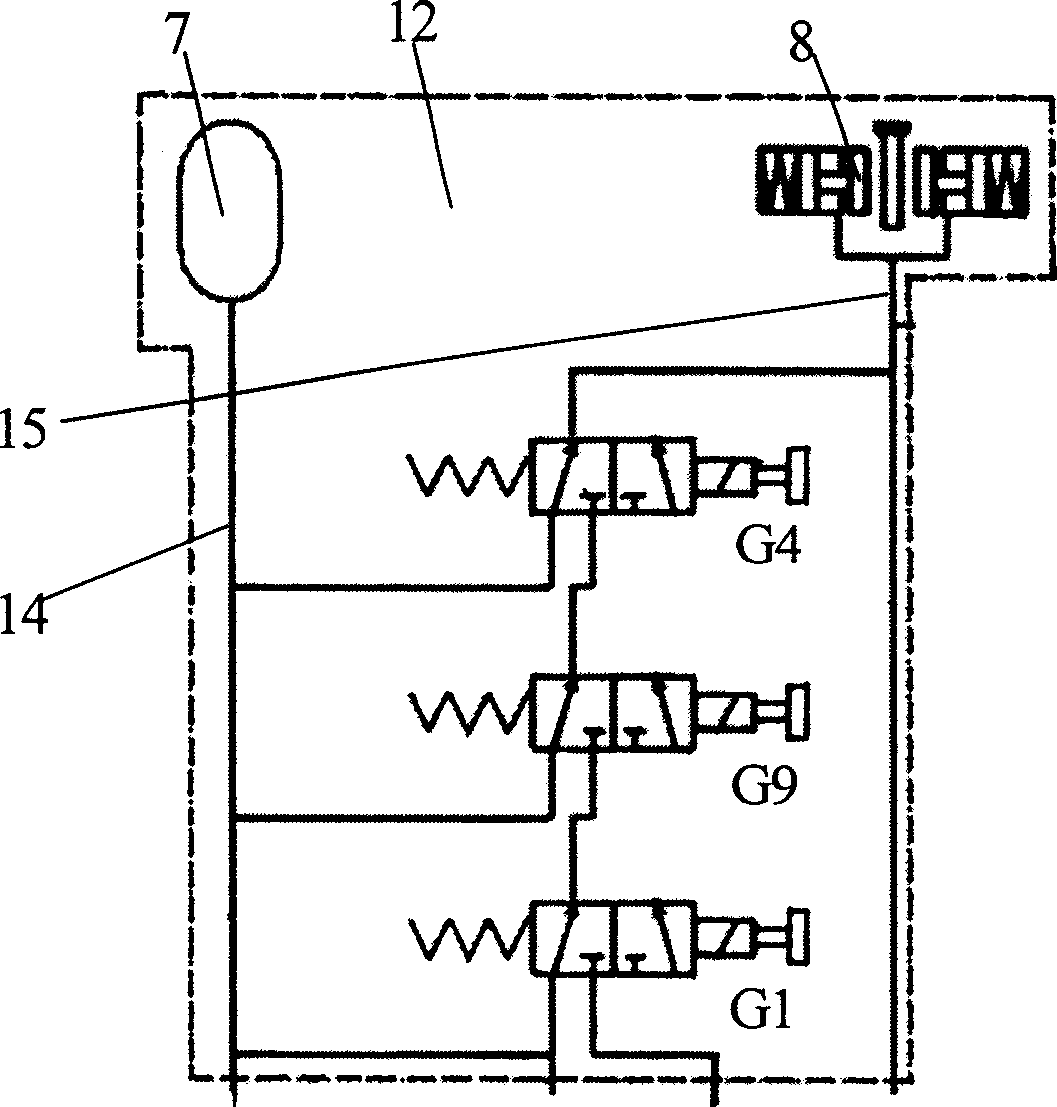

[0016] Embodiment one, figure 2 As shown, the secondary brake hydraulic station includes two sets of independent liquid supply devices consisting of an oil pump 1 and an electro-hydraulic pressure regulating device 3. Directional valve 2 is directly connected to group B brake brake 9, and the inlet and outlet of group B brake brake 9 is equipped with a normally open adjustable flow valve 11 connected to the fuel tank, and two solenoid valves directly connected to the fuel tank are connected in parallel on the pipeline. Reversing valves G7 and G8, and electromagnetic reversing valves G7 and G8 are equipped with sensors for online monitoring of reversing positions. Two electromagnetic directional valves G4 and G9 are connected in series in the pipeline connecting the brake brake 8 of group A, the accumulator 7 and the hydraulic directional valve 2, and online monitoring is installed on the two electromagnetic directional valves G4 and G9. Sensor for commutation position. The ...

Embodiment 2

[0017] Embodiment two, image 3 As shown, it is basically the same as the first embodiment, except that the multi-safety secondary brake valve circuit 12 in which the group A brake brake 8 communicates with the accumulator 7 and the hydraulic directional valve 2 is connected with three electromagnetic directional valves G4, G9 and G10 constitute the three-insurance secondary brake valve circuit, and the electromagnetic reversing valves G4, G9 and G10 are all equipped with sensors for online monitoring of the reversing position.

[0018] The control method of the secondary braking hydraulic station of the present invention:

[0019] During normal working braking, the hydraulic reversing valve 2 is controlled to supply fluid to the group A brake brake 8 and the B group brake brake 9, and the hydraulic oil is divided into two routes through the hydraulic reversing valve, and one route passes through the multi-insurance secondary brake valve circuit The two electromagnetic revers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com